Production technology of waste cloth strip and sludge fuel particles and equipment thereof

A fuel particle and production process technology, applied in the direction of waste fuel, fuel, solid fuel, etc., can solve the problems of low efficiency, large space occupation, loose waste cloth strips, etc., and achieve high economic benefits, improve combustion efficiency, and compact surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: a kind of production technology of waste cloth strip sludge fuel particle, comprises the following steps:

[0031] Include the following steps:

[0032] 1) The waste cloth strips are powder cut to obtain rags, which are transported to the quantitative barrel;

[0033] 2) The rags are evenly placed on the mixing conveyor belt by the quantitative material cylinder;

[0034] 3) The sludge is put on the mixing conveyor belt covered with rags through the auger, the rags account for 70%, and the rest is sludge;

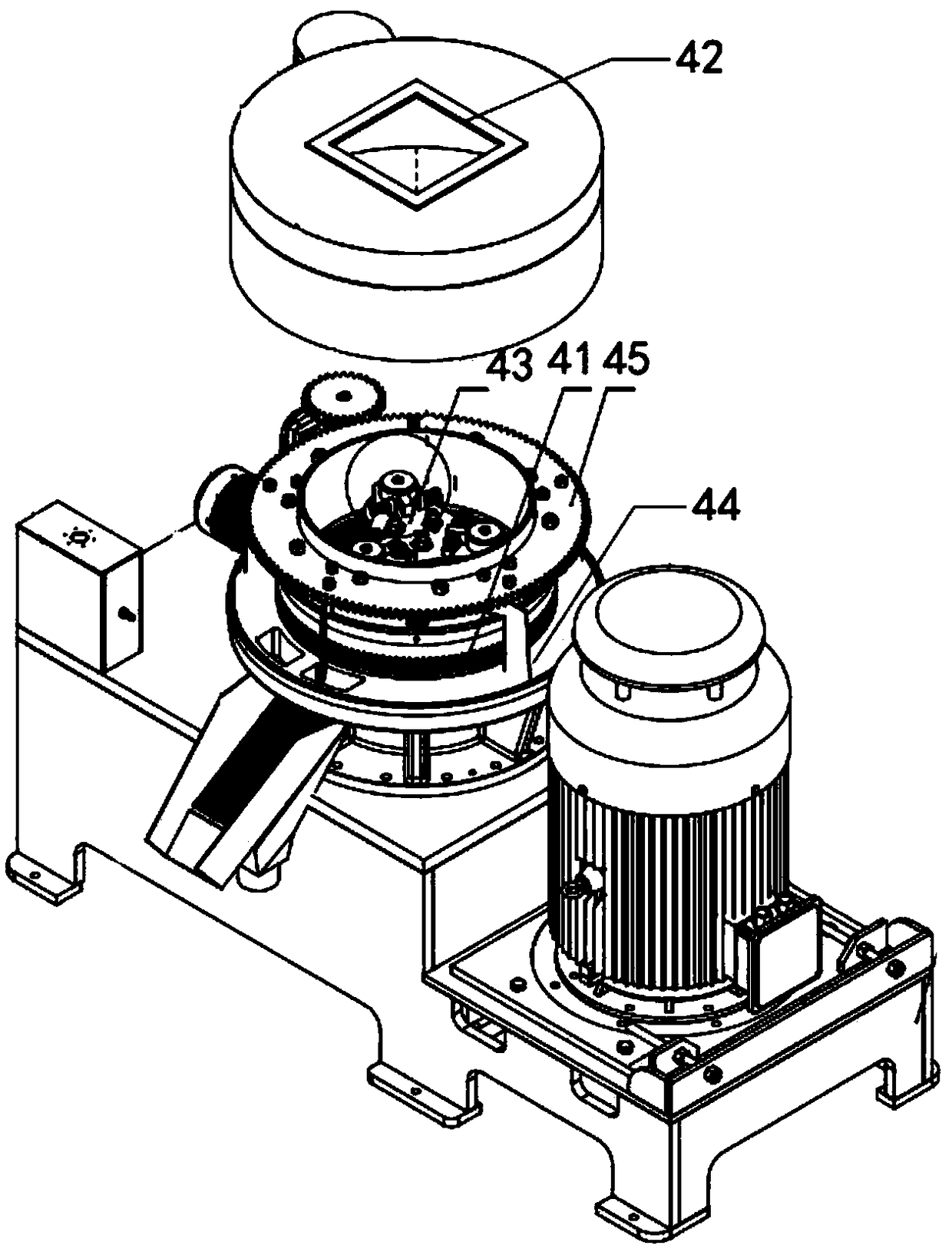

[0035] 4) The rags and sludge are mixed with planetary rollers in the granulation device. The revolution of the rollers is a reciprocating circular motion. The mixture is centrifugally extruded to produce fuel particles. The surface of the fuel particles is dense and the core has an air gap.

[0036] In step 4, the water content of the sludge is 30%.

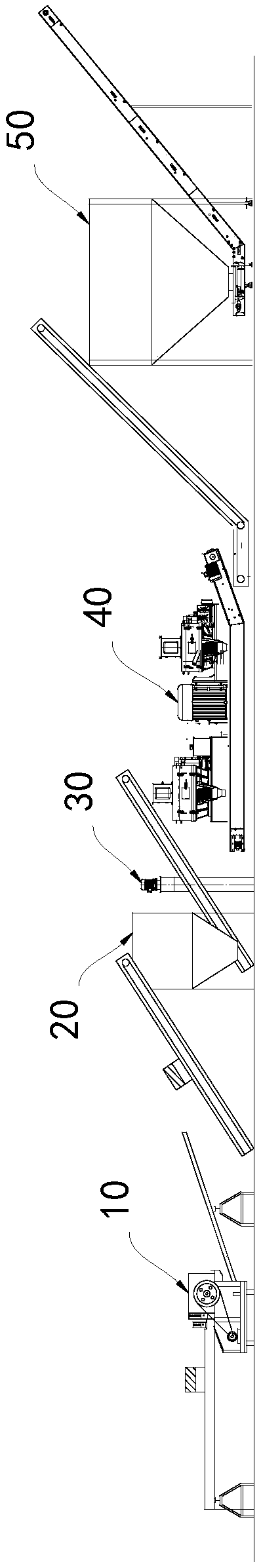

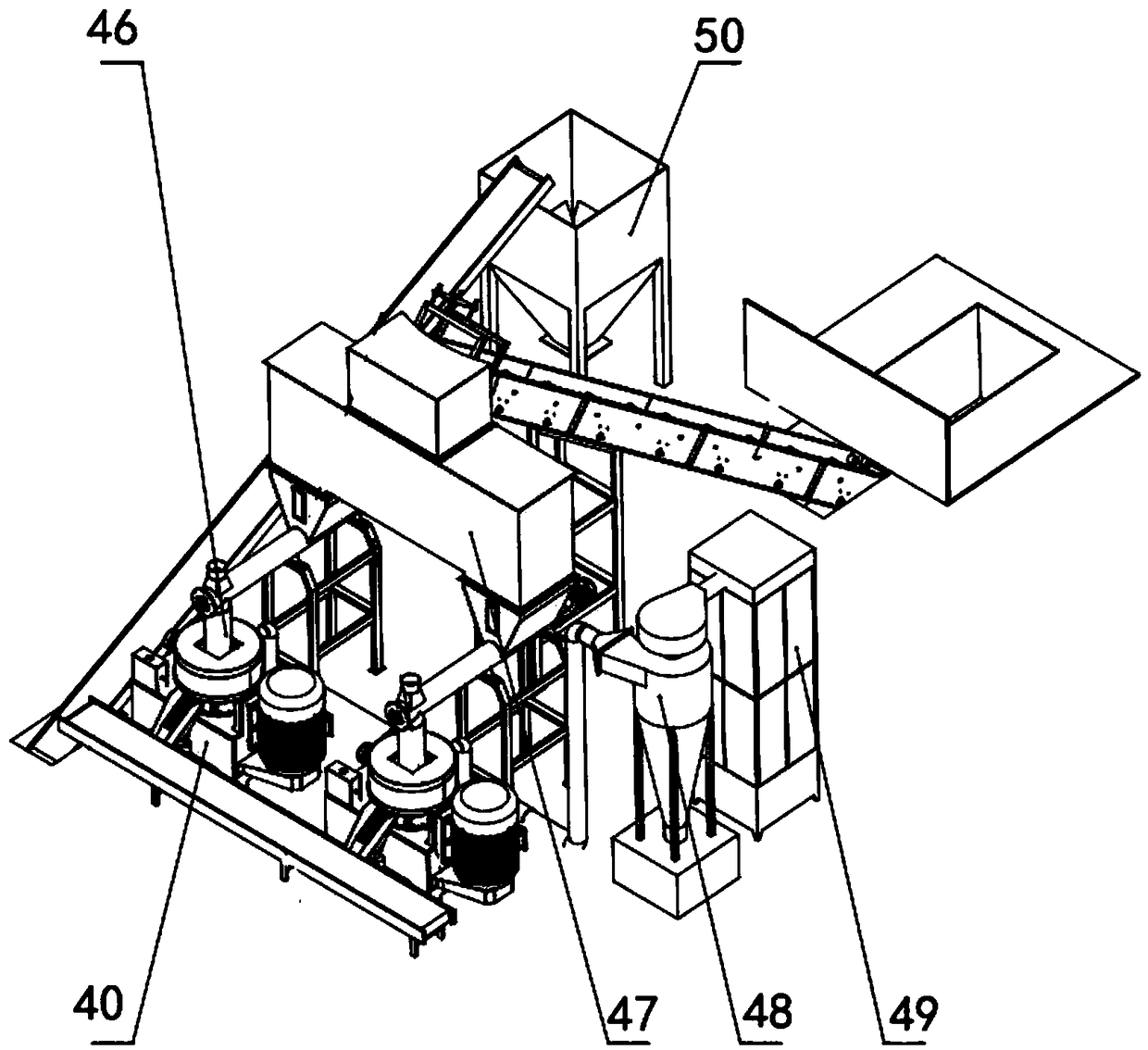

[0037] A kind of production equipment for the production process of waste cloth strips sludge fuel pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com