Adhesive applying device and method for bamboo skin coil

A bamboo strip roll and glue component technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of increased production cost, unenvironmental pollution, reduced tensile strength and mechanical strength, etc., and achieves the effect of reliable quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

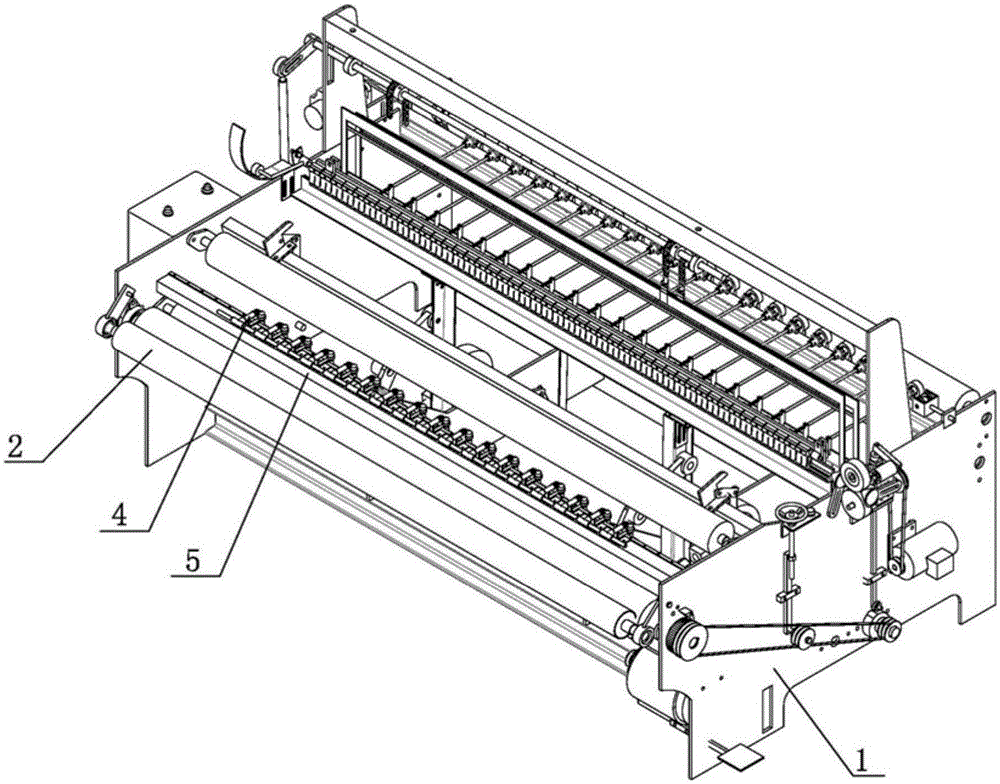

[0026] A glue application device for bamboo strip rolls, such as figure 1 As shown, it includes a frame 1 and a transmission part 2 of the bamboo strip roll, and a glue application part 4 connected to a glue source is provided on the transmission route of the bamboo strip roll. The glue application part 4 is a spray head, which has a plurality of nozzles, and is distributed on the mounting frame 5 perpendicular to the bamboo strip roll transmission direction, and its glue outlet corresponds to the braided wire 32 on the bamboo strip roll 3 .

[0027] When in use, all the nozzles are aimed at the braided wires in the gaps of the bamboo rolls to spray glue at the same time, and the bamboo rolls are controlled to drive a cutting step distance, and continue to spray glue for the next time.

Embodiment 2

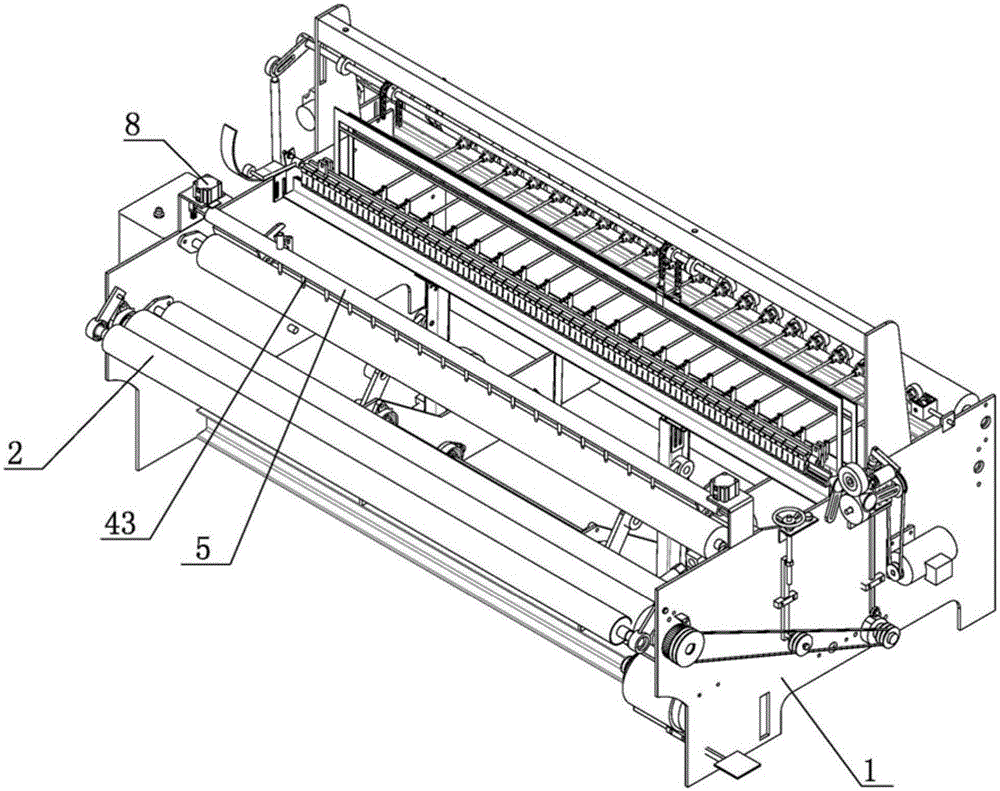

[0029] A glue application device for bamboo strip rolls, such as figure 2 As shown, it includes a frame 1 and a transmission part 2 of the bamboo strip roll, and a glue application part connected to a glue source is provided on the transmission route of the bamboo strip roll. Described gluing part is glue dispensing head 43, has a plurality of, is distributed on the mounting frame 5 perpendicular to the bamboo strip roll transmission direction, and its glue outlet is corresponding to the weaving line 32 on the bamboo strip roll 3. Cylinders 8 are arranged on both sides of the installation frame 5 where the dispensing head 43 is located.

[0030] During use, the installation frame 5 is controlled by the cylinder 8 to move in a direction close to the bamboo strip roll 3, so that all the dispensing heads 43 are aligned with the braided line positions in the gaps between the bamboo strip rolls for dispensing at the same time, and after the installation frame 5 returns, The bambo...

Embodiment 3

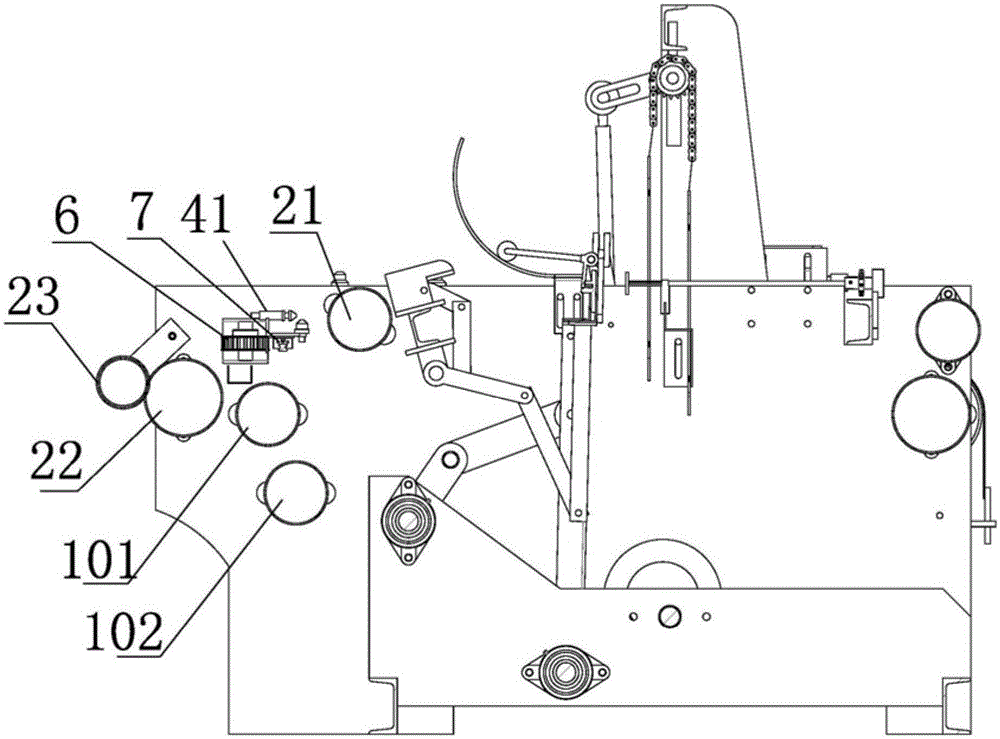

[0032] A glue application device for bamboo strip rolls, such as image 3 As shown, it includes a frame 1 and a transmission part 2 of the bamboo strip roll, and a glue application part connected to a glue source is provided on the transmission route of the bamboo strip roll. The above-mentioned transmission part 2 may include a guide roller 21, a driving roller 22, and a pinch roller 23, and the transmission route of the bamboo strip roll is to pass between the guide roller, the driving roller 22 and the pinch roller 23. The gluing part is a single spray head 41, which is arranged on the guide rail 7 perpendicular to the transmission direction of the bamboo strip roll, and the spray head 41 is connected with the synchronous belt 6.

[0033] When in use, the nozzle 41 is displaced along the guide rail 7 under the action of the synchronous belt 6. During the displacement process, the nozzle 41 continues to spray glue on the gaps between the bamboo strip rolls until all the brai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com