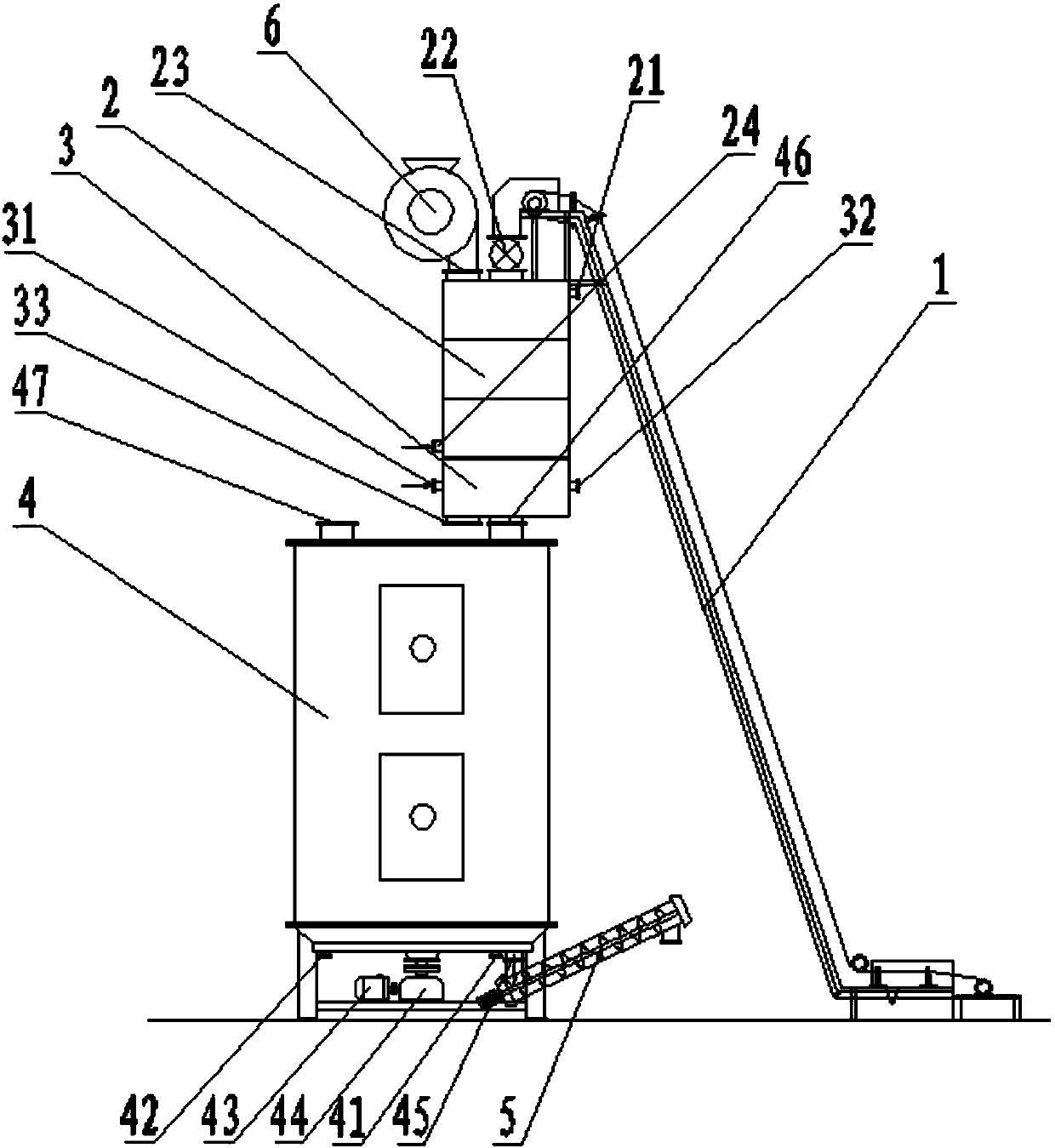

Sludge freezing pelletizing method and device

A frozen granulation and sludge technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problems of small application range, unfavorable energy saving, easy fracture and accumulation, etc. , to achieve the effect of reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

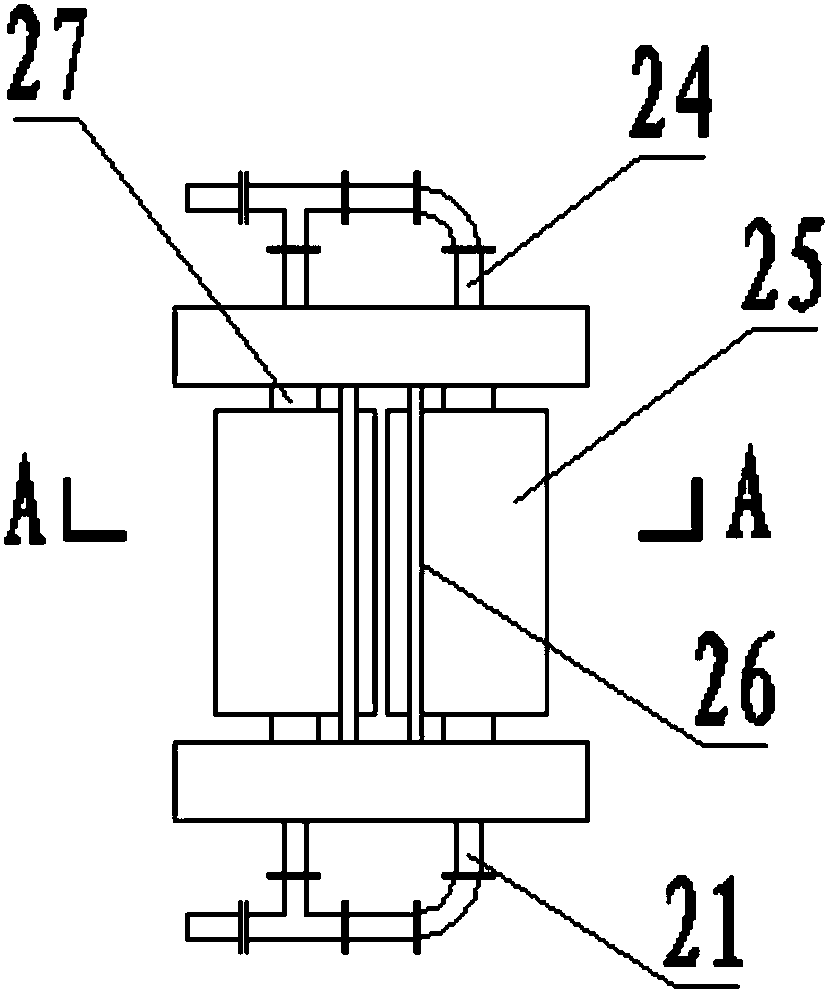

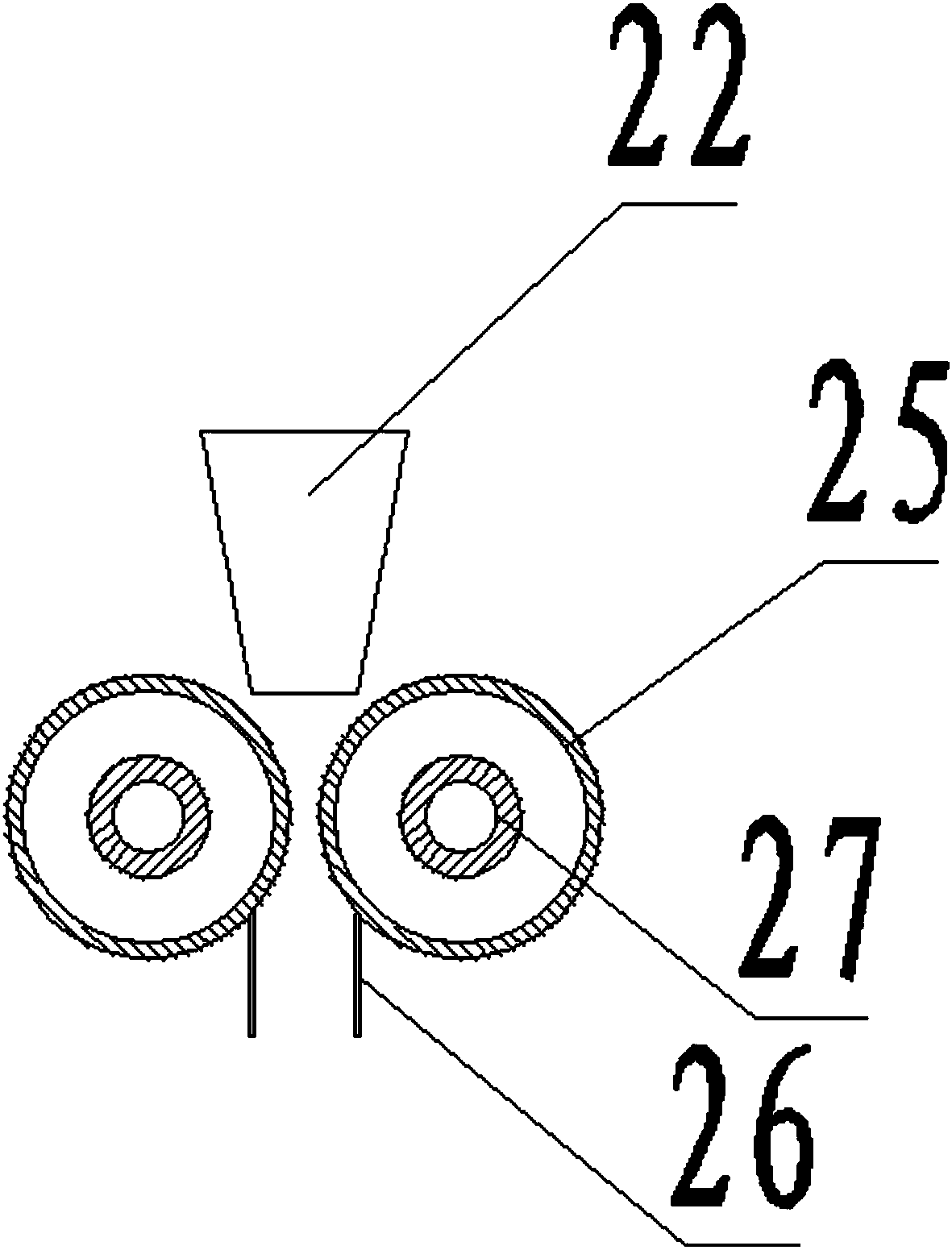

[0048] The main structure of this embodiment is substantially the same as that of Embodiment 1, and the difference is that: the number of stages of the roller press 2 is a natural number not greater than 10, preferably 3 stages, and the distance between the counter-rotating rollers 25 of the roller press 2 is in order Decrease; the number of 3 stages of the tooth knife granulator is a natural number not greater than 10, preferably 2 stages, and the spacing of the counter-rotating tooth cutters 34 of the tooth knife granulator 3 decreases successively. The purpose of this design is to ensure more efficient use of energy while ensuring the molding rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com