Pelletizing method of titanium concentrate

A titanium concentrate and granulation technology, applied in the field of metallurgy, can solve problems such as large size of titanium concentrate pellets, high molding cost, and reduced pellet quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add titanium concentrate and strengthening agent according to the mass ratio of titanium concentrate dry basis to strengthening agent 100:1.8 and mix well to obtain a mixture. The final moisture content of the mixture is 11.8%. The strengthening agent is composed of polyvinyl alcohol: medium temperature Asphalt powder: plant adhesive = 20:5:75;

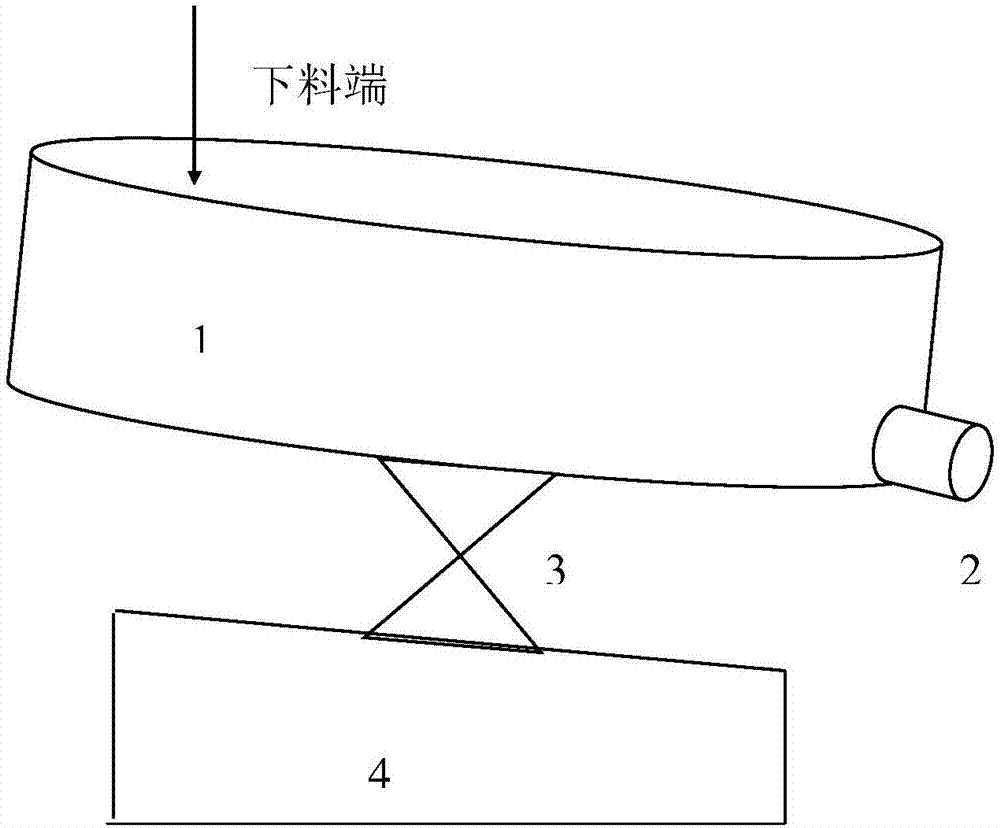

[0038] The above-mentioned mixture is granulated in an oscillating forming device with an inclination angle of 1° to obtain titanium concentrate forming wet granules; the vibration amplitude of the oscillating forming device is ±2cm, and the frequency is 12 times / s;

[0039] Pass the formed wet granules of titanium concentrate into the rotary kiln for drying with flue gas at 100°C, and finally obtain granulated dry particles of titanium concentrate, with a particle size of 3 mm to 8 mm, the mass ratio reaches 95.6%, and the average drop strength is 8.4 times / m.

Embodiment 2

[0041] Add titanium concentrate and strengthening agent according to the ratio of titanium concentrate dry weight to strengthening agent mass ratio of 100:1.3 and mix well to obtain a mixture. The final moisture content of the mixture is 13.4%. The strengthening agent is composed of polyvinyl alcohol: medium temperature Asphalt powder: plant adhesive = 60:10:30;

[0042] The above-mentioned mixture is granulated in an oscillating forming device with an inclination angle of 2.5° to obtain titanium concentrate forming wet granules; the vibration amplitude of the oscillating forming device is ±7cm, and the frequency is 5 times / s;

[0043] Pass the ilmenite concentrate shaped wet granules into the rotary kiln for flue gas drying at 220°C, and finally get the ilmenite concentrate granulated dry granules, the mass proportion of which is within the range of 3 mm to 8 mm in particle size reaches 91%, and the average drop strength is 5.4 times / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com