Special binding agent for converter dedusting ash cold-pressed pellets

A converter technology for dust removal and cold-pressing pellets, applied in the field of smelting, can solve problems such as insufficient strength and pulverization, and achieve the effects of reducing the pulverization rate, increasing the strength, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

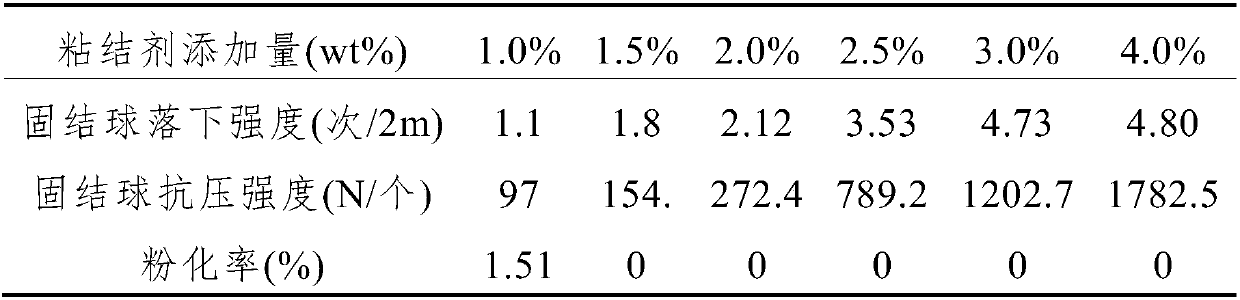

Embodiment 1

[0030] The binder in the present embodiment is weighed by weight ratio: 1 part of syrup, 15 parts of ammonium carbonate and 2 parts of sodium carboxymethyl cellulose. When in use, mix ammonium carbonate and sodium carboxymethyl cellulose according to Add the required proportion to the converter dust removal ash, and then take the syrup according to the proportion and add it to the converter dust removal ash, spray 6% water and mix well, press it into a ball with a jack, and test the falling strength of the pellet after solidifying in the air for 24 hours , compressive strength and pulverization rate, the test method is as follows:

[0031] Drop strength: Randomly select 10 pellets, each of which falls freely from a height of 2m onto a steel plate with a thickness of 10cm, counts the number of times when it breaks as the drop strength of the pellet, and finally calculates the average value as the group of pellets drop strength index.

[0032] For compressive strength, 10 pelle...

Embodiment 2

[0042]The binding agent in the present embodiment, carry out by weight ratio: 0.6 part of syrup, 20 parts of ammonium carbonate and 1.4 parts of sodium carboxymethyl cellulose, add the binding agent that weight ratio is 3% in converter dedusting ash, namely 97 parts by weight of converter dust and 3 parts by weight of binder, wherein 0.082 parts by weight of syrup, 2.727 parts by weight of ammonium carbonate, and 0.191 parts by weight of sodium carboxymethyl cellulose can be added respectively in the binder, or can be added after mixing 97 parts by weight of the converter dust, after that, sprayed with different amounts of water, mixed evenly, pressed into balls with a jack, consolidated in the air for 24 hours, measured with the method in Example 1. Wherein, the amount of water added is calculated according to the weight percentage of the total amount of converter dust and binder.

[0043] The results show that with the increase of the amount of water added, such as from 4% t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com