Preparation method of steel slag mould sand

A technology of molding sand and steel slag, which is applied in the field of wear-resistant building materials production, can solve problems such as polluting the environment and occupying space, and achieves the effects of low metal iron content, good quality and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

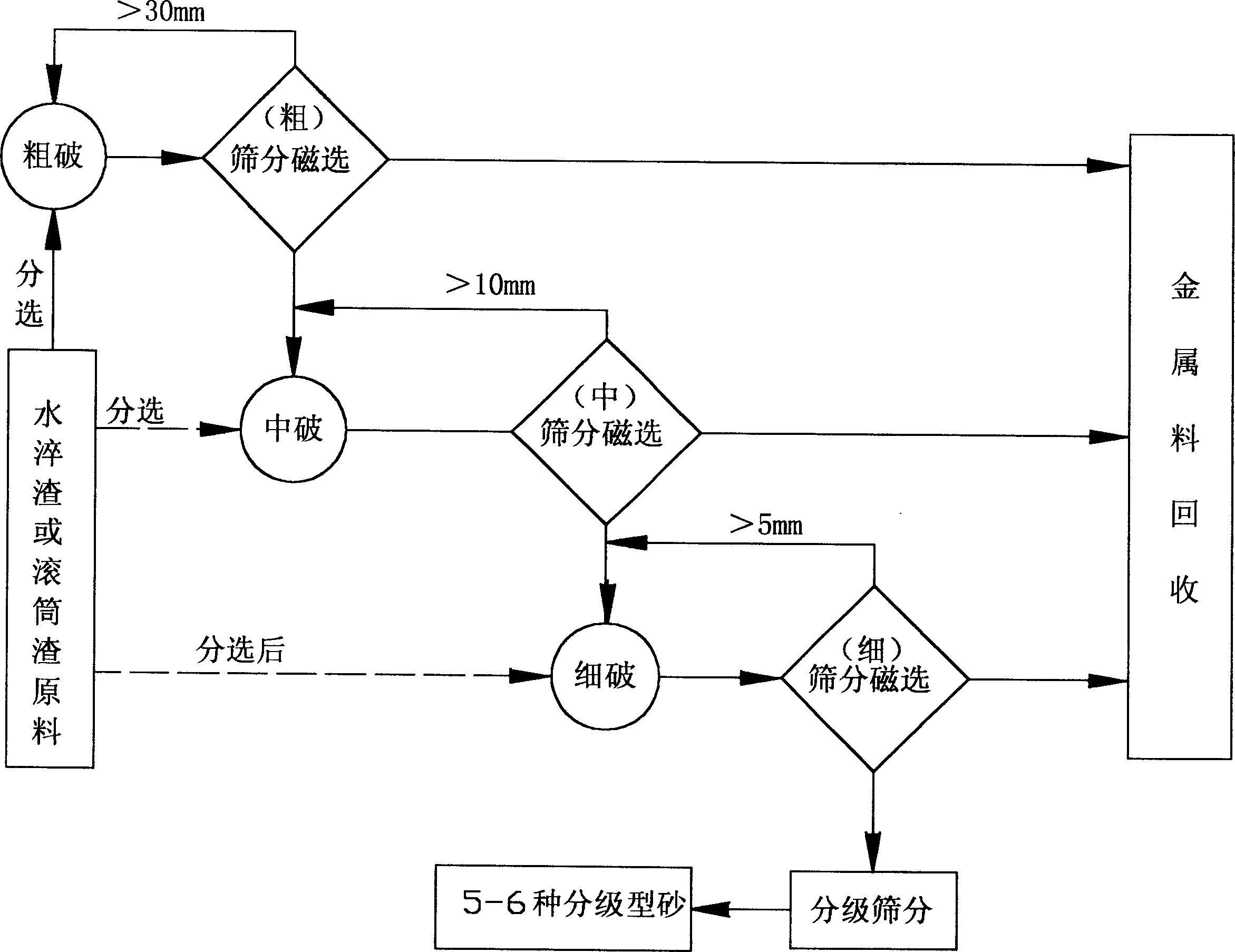

[0015] figure 1 Shown is a flow chart of the production process of steel slag molding sand. The preparation method of the steel slag molding sand is to process the converter steel slag through water injection and quenching process, and then perform magnetic separation and crushing on the formed water-quenched steel slag or drum slag , Filtered.

[0016] The steel slag molding sand formed after the water-quenched steel slag or drum slag is processed is a molding sand with a grain size less than or equal to 5mm and with different specifications or meshes.

[0017] The specific operation methods for magnetic separation, crushing and screening of the formed water-quenched steel slag or drum slag are as follows:

[0018] (1) Take water-quenched steel slag or drum slag by coarse, medium and fine crushing methods, classify, sieve and magnetically s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com