Urea resin foam material prepared by microwave foaming and preparation method of urea resin foam material

A technology of urea-formaldehyde resin foam and microwave foaming, which is applied in the field of foam materials and their preparation, can solve the problems that the preparation method of urea-formaldehyde foam materials has not been reported, and achieve the effects of shortening heating time, good flame retardancy and low fire risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

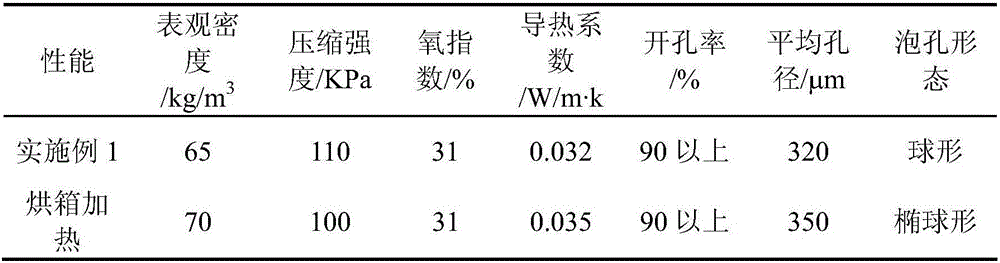

Examples

Embodiment 1

[0039] (1) Preparation of microwave foamable urea-formaldehyde resin

[0040] Calculate the feeding amount with the molar ratio of urea and formaldehyde being 1.4:1, and add the weighed formaldehyde aqueous solution with a mass fraction of 37% into the reaction kettle in advance, and start stirring. Use 30% NaOH aqueous solution to adjust the pH value of formaldehyde to 8.8, then add the first batch of urea, and raise the temperature to 85°C for half an hour. Immediately after the heat preservation stage is over, adjust the pH value of the reaction system to 4.8 with 0.5 mol / L hydrochloric acid aqueous solution, and at the same time warm to 90°C, and react under these conditions until the viscosity reaches 18s. The temperature was lowered to 75° C., and the pH value of the system was adjusted to 6.0 with 30 wt % NaOH aqueous solution immediately, and the second batch of urea was added. After reacting for 30 minutes, adjust the pH value to 7.6, add the third batch of urea, con...

Embodiment 2

[0052] (1) Preparation of microwave foamable urea-formaldehyde resin

[0053] Calculate the feeding amount with the molar ratio of urea and formaldehyde being 1.3:1, and add the weighed formaldehyde aqueous solution with a mass fraction of 37% into the reaction kettle in advance, and start stirring. Use 30% NaOH aqueous solution to adjust the pH value of formaldehyde to 8.8, then add the first batch of urea, and raise the temperature to 85°C for half an hour. Immediately after the heat preservation stage is over, adjust the pH value of the reaction system to 5.1 with 0.5 mol / L hydrochloric acid aqueous solution, and at the same time warm to 95°C, and react under these conditions until the viscosity reaches 18.5s. The temperature was lowered to 75° C., and the pH value of the system was adjusted to 5.8 with 30 wt % NaOH aqueous solution immediately, and the second batch of urea was added. After reacting for 30 minutes, adjust the pH value to 7.5, add the third batch of urea, c...

Embodiment 3

[0061] (1) Preparation of microwave foamable urea-formaldehyde resin

[0062] Calculate the feeding amount with the molar ratio of urea and formaldehyde being 1.3:1, and add the weighed formaldehyde aqueous solution with a mass fraction of 37% into the reaction kettle in advance, and start stirring. Use 30% NaOH aqueous solution to adjust the pH value of formaldehyde to 8.8, then add the first batch of urea, and raise the temperature to 80°C for half an hour. Immediately after the heat preservation stage is over, adjust the pH value of the reaction system to 5.1 with 0.5 mol / L hydrochloric acid aqueous solution, and at the same time warm to 95°C, and react under these conditions until the viscosity reaches 18s. The temperature was lowered to 75° C., and the pH value of the system was adjusted to 5.8 with 30 wt % NaOH aqueous solution immediately, and the second batch of urea was added. After reacting for 30 minutes, adjust the pH value to 7.6, add the third batch of urea, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com