Method for preparing full-vanadium-titanium pellets

A technology of pelletizing and vanadium-titanium, which is applied in the field of preparing all-vanadium-titanium pellets, can solve problems such as methods to be studied, and achieve the effects of large porosity, compressive strength, and shortening of pelletizing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

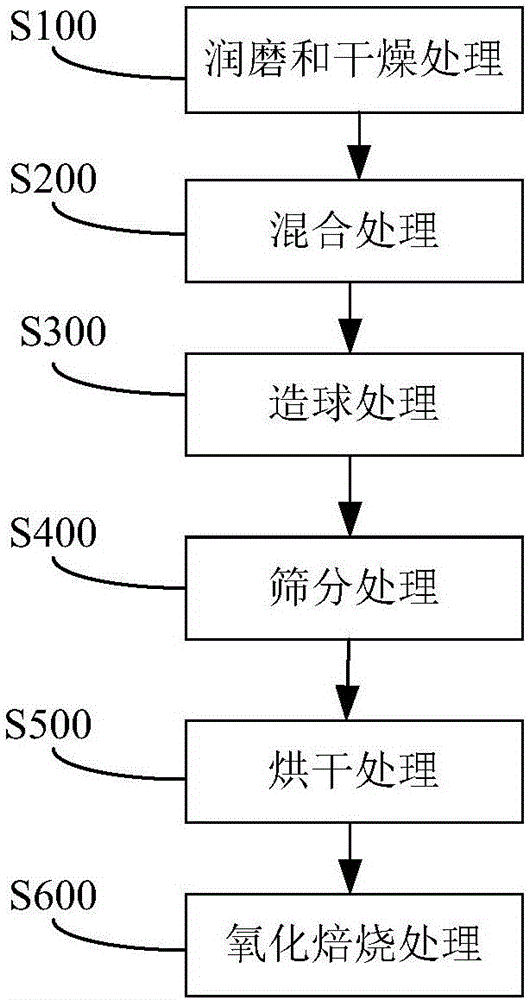

Method used

Image

Examples

Embodiment 1

[0049] Chengde vanadium-titanium magnetite and bentonite are used as raw materials to prepare all-vanadium-titanium pellets. Among them, the water content of Chengde vanadium-titanium magnetite is 1.3%, and the main components and particle size distribution are as follows:

[0050] The main components of Chengde vanadium-titanium magnetite are:

[0051] TF FeO V 2 o 5

TiO 2

SiO 2

CaO MgO al 2 o 3

S P 57.22 27.5 0.498 7.77 1.57 1.01 1.00 2.09 0.049 0.058

[0052] The particle size distribution of Chengde vanadium-titanium magnetite is:

[0053] Grain fraction / mm +0.15 -0.15~+0.10 -0.10~+0.074 -0.074~+0.045 -0.074 -0.045 content / % 0.8 2.4 17.6 48.7 79.2 30.5

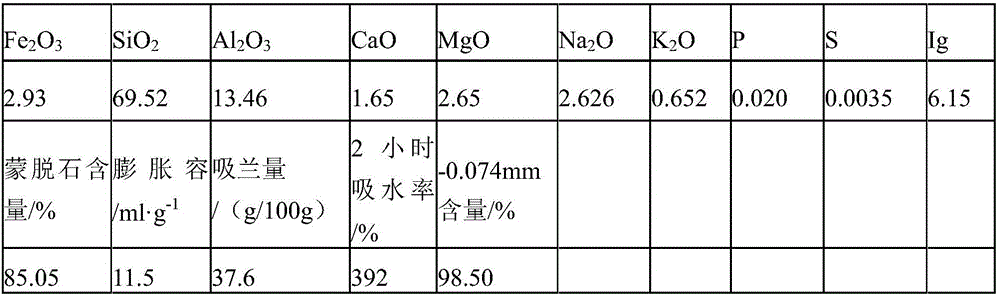

[0054] The main components of bentonite:

[0055]

[0056] Utilize above-mentioned raw material to prepare the method for pellet as follows:

[0057] (1) Add 2% by mass of bentonite to Chengde vanadium-titanium magnetite.

...

Embodiment 2

[0066] Using Kazakhstan vanadium-titanium magnetite and bentonite as raw materials to prepare all-vanadium-titanium pellets, wherein the water content of Kazakhstan vanadium-titanium magnetite is 1.0%, and the main components and particle size distribution are as follows:

[0067] Main components of vanadium-titanium magnetite in Kazakhstan

[0068] TF FeO V 2 o 5

TiO 2

SiO 2

CaO MgO Al 2 o 3

S P 67.29 27.5 0.546 1.47 1.57 0.66 0.51 0.83 0.001 0.006

[0069] Particle Size Distribution of Vanadium-Titanium Magnetite in Kazakhstan

[0070] Grain fraction / mm +0.15 -0.15~+0.10 -0.10~+0.074 -0.074~+0.045 -0.074 -0.045 content / % 2.04 4.28 3.35 42.00 90.33 48.33

[0071] The main components of bentonite:

[0072]

[0073] (1) Add 0.8% by mass of bentonite to Kazakhstan vanadium-titanium magnetite.

[0074] (2) Dry blend the materials obtained in step (1). After the materials are evenly...

Embodiment 3

[0082] Using Mozambique vanadium-titanium magnetite and bentonite as raw materials, all-vanadium-titanium pellets are prepared. Among them, the water content of Mozambique vanadium-titanium magnetite is 0.8%, and the main components and particle size distribution are as follows:

[0083] The main components of vanadium-titanium magnetite in Mozambique are:

[0084] TF FeO V 2 o 5

TiO 2

SiO 2

CaO MgO Al 2 o 3

S P MnO Cr 2 o 3

54.16 9.91 0.815 16.16 1.69 0.36 0.86 3.25 0.01 0.01 0.26 0.24

[0085] Mozambique vanadium-titanium magnetite particle size distribution is:

[0086]

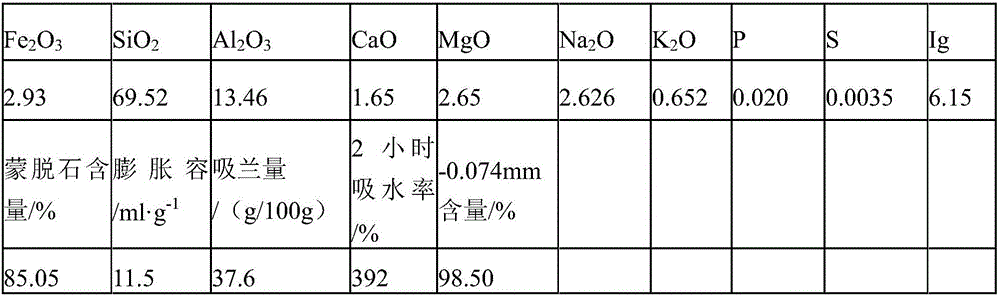

[0087] The main components of bentonite:

[0088]

[0089] Utilize above-mentioned raw material to prepare the method for pellet as follows:

[0090] (1) Mozambique vanadium-titanium magnetite was added with 2% by mass of bentonite.

[0091] (2) Dry blend the materials obtained in step (1). After the materials are evenly mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com