Mercury removal agent with copper sulfide and method for preparing mercury removal agent

A copper sulfide and mercury removal technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex method steps, limited content of active components in products, and low mercury content, and achieve The effect of preventing microstructure collapse, good workshop operating environment, and high mercury capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

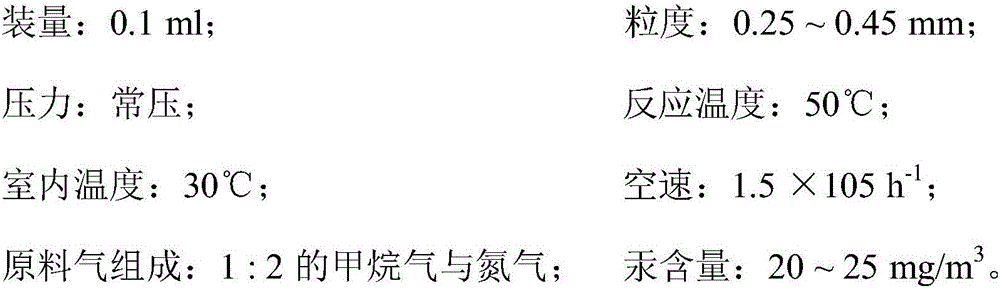

Embodiment 1

[0034] Configure sodium sulfide solution 11.0L, where S 2- The ion concentration is 0.1mol / L; the metal salt solution is 10.0L, wherein copper nitrate is 0.1mol / L, then the copper nitrate solution is added to the sodium sulfide solution at normal temperature, and when the pH is 7, the reaction is stopped, and the resulting product is filtered, Wash and dry at 50°C to obtain active copper sulfide.

[0035] After uniformly mixing 10 parts of active copper sulfide, 85 parts of pseudoboehmite and 10 parts of water, put it into a rolling ball machine and roll it, and spray into silica sol with a solid content of 20%. The particle size of the silica sol used is 8nm, and the amount of silica sol It is 30% of the mass of the mixture, rolled into a spherical object, and dried to obtain a finished mercury removal agent with a diameter of 2 to 5 mm.

Embodiment 2

[0037] Prepare 2.3L of sodium sulfide solution, in which the S2- ion concentration is 0.5mol / L; 10.0L of metal salt solution, including 0.1mol / L of copper nitrate and 0.002mol / L of iron nitrate, and then add the copper salt solution to sulfide at 50°C In the sodium solution, when the pH is 9, the reaction is stopped, the obtained product is filtered, washed, and dried at 50°C to obtain active copper sulfide.

[0038] After uniformly mixing 20 parts of active copper sulfide, 68 parts of α-aluminum hydroxide and 10 parts of water, put it into a rolling ball machine and roll it, and spray into silica sol with a solid content of 30%. The particle size of the silica sol used is 15nm. The dosage is 45% of the mass of the mixture, rolled into a spherical shape, and dried to obtain a finished mercury removal agent with a diameter of 3-5 mm.

Embodiment 3

[0040] Prepare 2.0L of ammonium sulfide solution, in which the S2- ion concentration is 2mol / L; 6.0L of metal salt solution, in which copper sulfate is 0.5mol / L, iron sulfate is 0.02mol / L, magnesium sulfate is 0.08mol / L, and then Add the copper salt solution into the sodium sulfide solution, stop the reaction when the pH is 10, filter and wash the obtained product, and dry at 70°C to obtain active copper sulfide.

[0041] After uniformly mixing 45 parts of active copper sulfide, 50 parts of quick-release powder and 10 parts of water, put it into a rolling ball machine and roll it, spray into silica sol with a solid content of 20%, the particle size of the silica sol used is 40nm, and the amount of silica sol is 33% of the mass of the mixture, rolled into a spherical object, and dried to obtain a finished mercury removal agent with a diameter of 2 to 4 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com