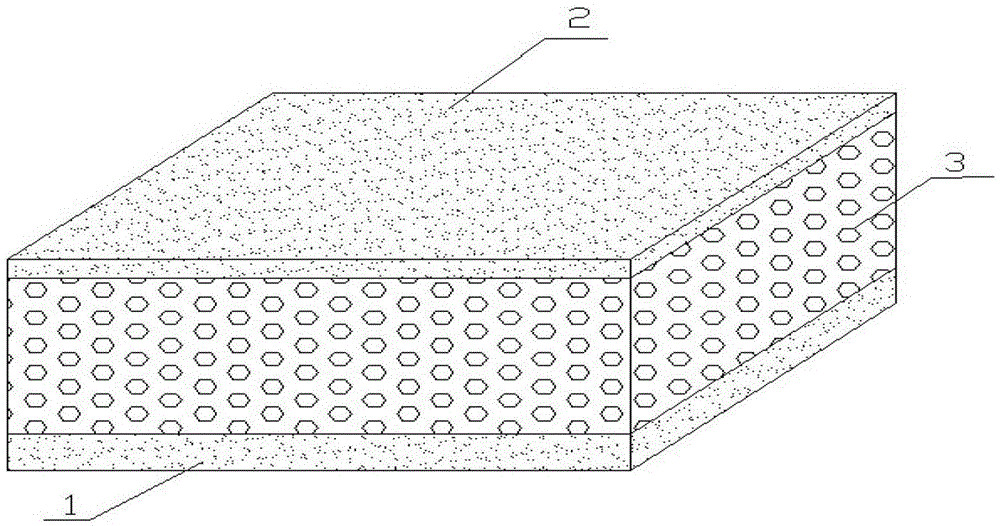

Explosion-proof heat-preservation multifunctional sheet material of foaming concrete sandwich and preparation method of material

A foamed concrete, multi-functional technology, applied in the direction of thermal insulation, chemical instruments and methods, ceramic products, etc., can solve the problems of devastating damage, damage to the main structure of buildings, endangering people's lives and property safety, and achieve strong blast resistance The effect of ability and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

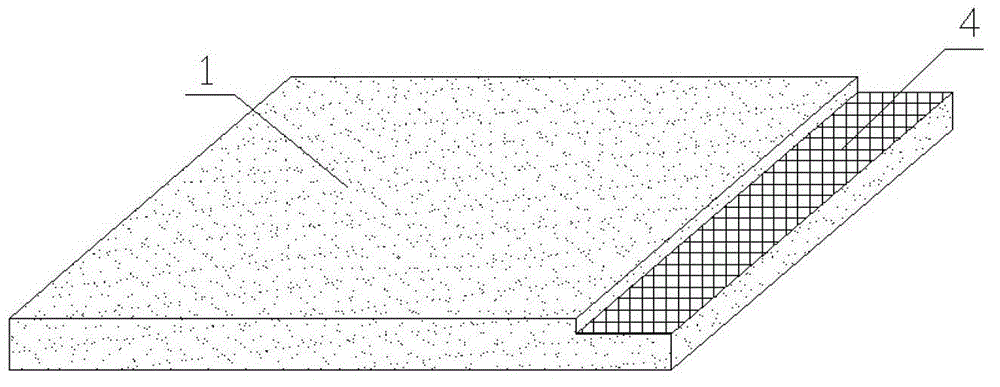

[0049] A Preparation of explosion-proof lightweight mortar outer guard plate:

[0050] 1) Mix 725 high-strength cement and water according to the mass ratio of 0.4:1, and the total weight is 55 kg. Add it to the mixer and stir for 8 minutes;

[0051] 2) Add 40 kg of lightweight aggregate shale ceramsite, 3 kg of starch ether, and 2 kg of latex powder to the slurry formed in step 1) and stir for 6 minutes;

[0052] 3) After stirring evenly, pour it into the mold, add a layer of metal grid reinforcement layer when pouring half, and then pour the remaining half, the thickness is about 5-20mm;

[0053] 4) Moisturize and maintain according to the traditional process, and finally demould;

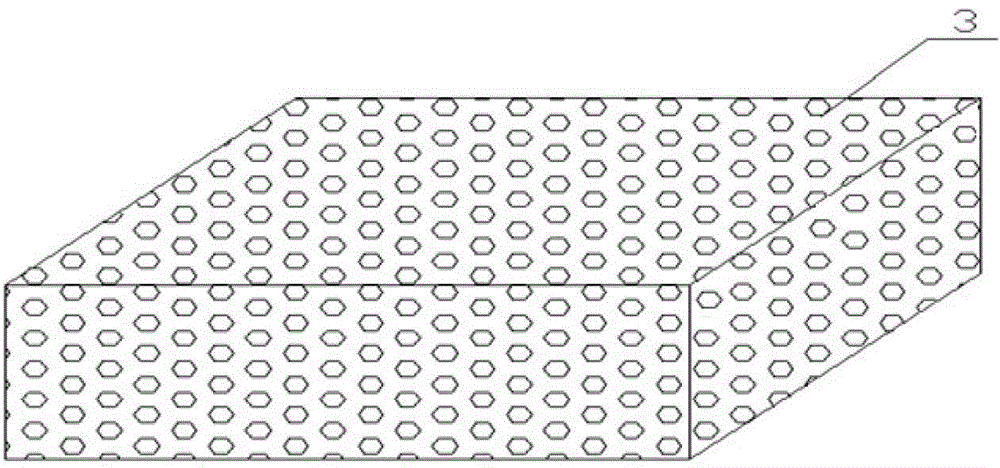

[0054] B preparation of foam concrete core:

[0055] 1) Mix 20 kg of foaming agent hydrogen peroxide, 0.5 kg of VA-01 emulsion or styrene-butadiene emulsion, and 156 kg of water and stir for 2 minutes to make it uniform;

[0056] 2) Add 50 kg of 32.5R Portland cement, 20 kg of fly ash, and 8 k...

Embodiment 2

[0060] Explosion-proof lightweight mortar outer guard plate:

[0061] 1) Mix 52.5R sulfoaluminate cement and water according to the mass ratio of 0.5:1, and the total weight is 70 kg. Add it into the mixer and stir for 5 minutes;

[0062] 2) Add 45 kg of lightweight aggregate pumice or tuff to the slurry formed in step 1), 2 kg of polymer modified additive lignocellulose, hydroxypropyl methylcellulose (HPMC) or polypropylene fiber, and 3 kg of latex powder Kilograms were stirred and stirred for 5 minutes;

[0063] 3) After stirring evenly, pour it into the mold, add a layer of metal grid reinforcement layer when pouring half, and then pour the remaining half, the thickness is about 5-20mm;

[0064] 4) Moisturize and maintain according to the traditional process, and finally demould;

[0065] B preparation of foam concrete core:

[0066] 1) Mix 30 kg of LC-2 composite cement foaming agent, 0.3 kg of hydraulic calcium stearate emulsion or vinyl-acrylate copolymer emulsion, an...

Embodiment 3

[0071] Explosion-proof lightweight mortar outer guard plate:

[0072] 1) Mix 62.5R slag Portland cement and water according to the mass ratio of 0.7:1, and the total weight is 50 kg. Add it into the mixer and stir for 3 minutes;

[0073] 2) Add 25 kg of industrial waste light aggregate slag, fly ash ceramsite or natural coal gangue, 4 kg of polymer modification additive polyvinyl alcohol micropowder, and 1 kg of latex powder to the slurry formed in step 1), and stir. Stir for 3 minutes;

[0074] 3) After stirring evenly, pour it into the mold, add a layer of metal grid reinforcement layer when pouring half, and then pour the remaining half, the thickness is about 5-20mm;

[0075] 4) Moisturize and maintain according to the traditional process, and finally demould;

[0076] B preparation of foam concrete core:

[0077] 1) Mix 12 kg of foaming agent sodium lauryl sulfate (K12), 0.4 kg of VA-01 emulsion, and 216 kg of water and stir for 7 minutes to make it uniform;

[0078] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com