Insulating decoration integral board for building exterior wall

A technology of building exterior walls and integrated panels, applied in construction, building structure, lamination devices, etc., can solve problems such as large drying shrinkage stress, affecting thermal insulation effect, easy cracking, etc., to improve crack resistance and flexibility, Ensure the effect of heat insulation and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The thermal insulation and decoration integrated board for building exterior walls includes a thermal insulation layer, a single combination layer and a decorative layer. The insulation layer is made of XPS insulation board, the bonding layer is a polymer adhesive layer, and the facing layer is made of aluminum-plastic board. The thickness of the thermal insulation and decoration integrated board is 40mm.

Embodiment 2

[0077] The thermal insulation and decoration integrated board for the exterior wall of the building includes a thermal insulation layer, a bonding layer and a decorative layer. The material of the thermal insulation layer is EPX thermal insulation board, the bonding layer is a composite bonding layer, and the decorative layer is made of imitation granite real stone paint film. The exterior wall thermal insulation and decoration integrated board is successively composed of thermal insulation layer, polymer bonding mortar layer, alkali-resistant glass fiber mesh cloth, polymer plastering mortar layer, exterior wall putty layer, and decorative surface from the inside to the outside from the insulation layer. decorative layer. The thickness of the thermal insulation and decoration integrated board is 55mm, and the thickness of the bonding layer is 5mm.

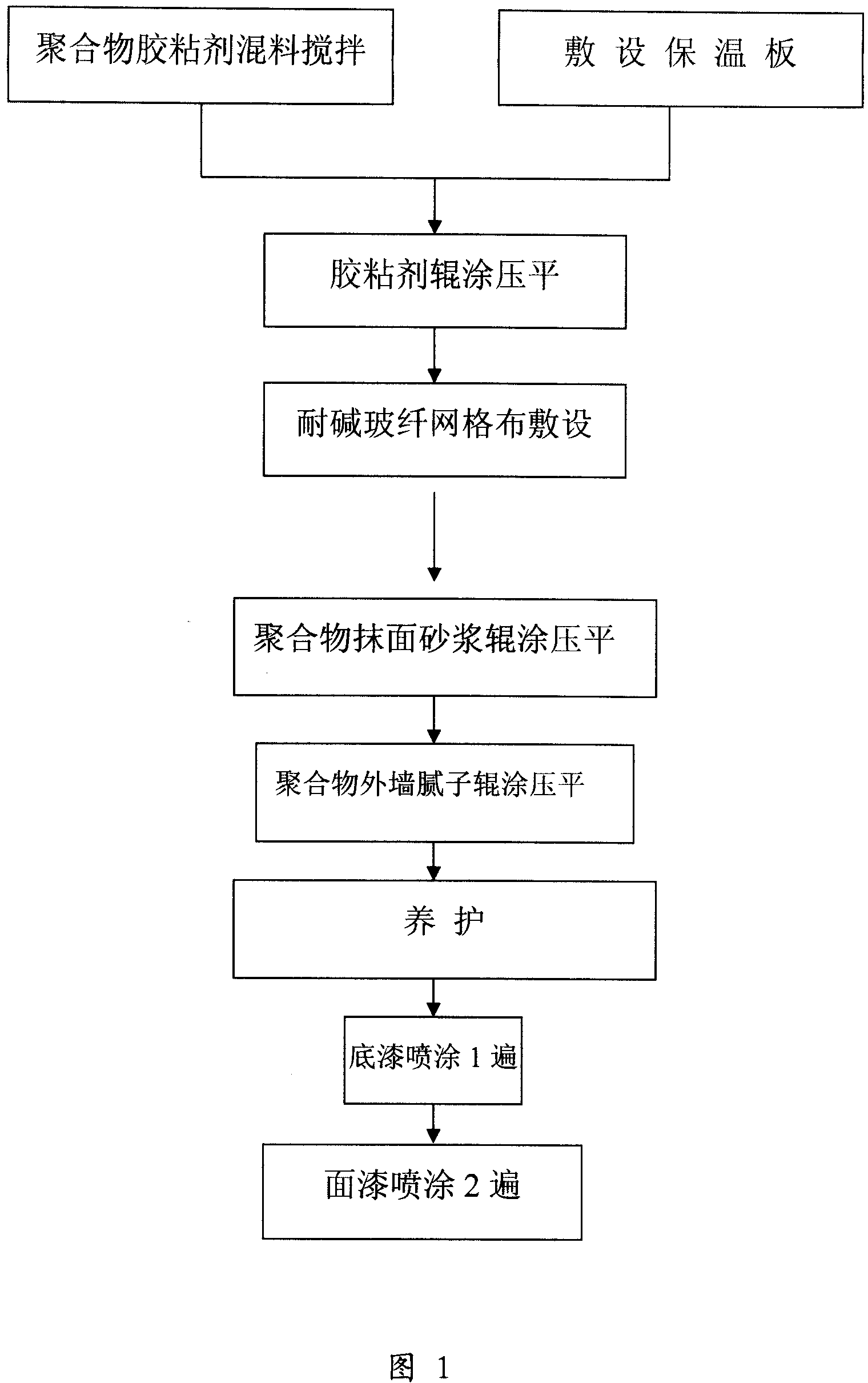

[0078] The production method of the exterior wall thermal insulation and decoration integrated board is as follows:

[0079] Th...

Embodiment 3

[0082] The parts by weight of each component in the adhesive mortar dry powder used in the adhesive mortar layer in the above-mentioned embodiment 2 are as follows:

[0083] 42.5R Ordinary Portland Cement 31

[0084] 60 mesh quartz sand 58

[0085] 250 mesh heavy calcium carbonate 8.5

[0086] SP-3000 dispersible rubber powder 2.1

[0087] Methyl cellulose ether 0.18

[0088] 0.8mm polypropylene fiber 0.12

[0089] Commercially available building defoamer 0.1

[0090] During production and use, add 22kg of neutral water to every 100kg of the above-mentioned glue dry powder, and stir to make glue for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com