Binding composition, electric circuit connecting material, electric component connecting structure and production thereof

A technology for circuit connection materials and circuit components, applied in the direction of circuits, adhesives, electrical components, etc., can solve problems such as the adverse effects of surrounding components, and achieve the effects of low connection resistance, good stability, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0029] adhesive composition

[0030] The adhesive composition of the present invention contains a radical polymerizable compound, a radical polymerization initiator, and a compound having a nitrogen-silicon bond.

[0031]A radically polymerizable compound is a compound having a functional group polymerizable by radicals. Radical polymerizable compounds include, for example, (meth)acrylate compounds, maleimide compounds, citraconimide compounds, indophenolimide (najimid) compounds, and the like. These may be used alone or in combination of two or more. In addition, the radically polymerizable compound may be used either in the form of a monomer or an oligomer, or may be used as a mixture of monomers and oligomers.

[0032] Examples of (meth)acrylate compounds include: methyl (meth)acrylate, ethyl (meth)acrylate, isopropyl (meth)acrylate, isobutyl (meth)acrylate, ethyl (meth)acrylate Diol ester, diethylene glycol di(meth)acrylate, trimethylolpropyl tri(meth)acrylate, tetramet...

no. 2 Embodiment approach

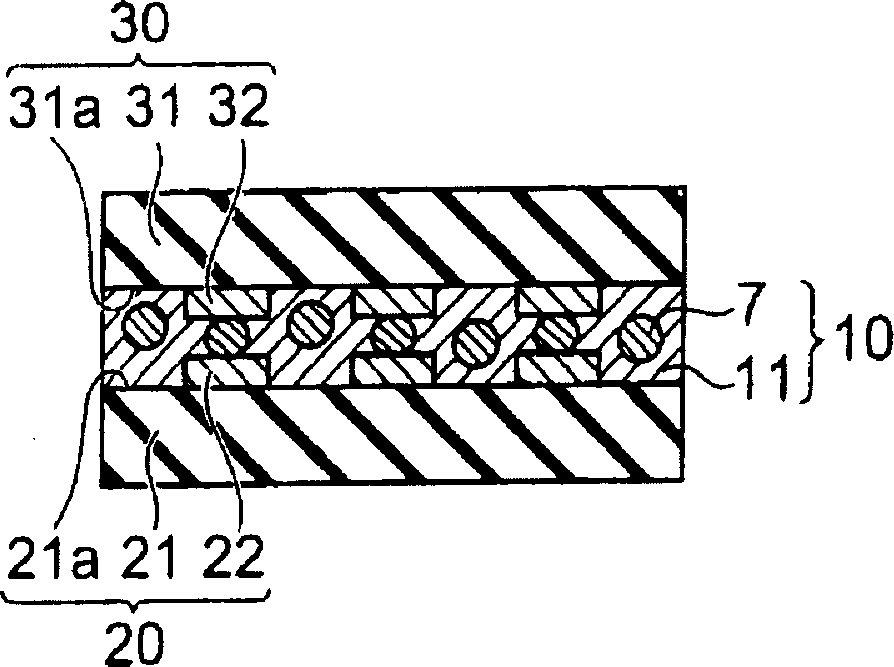

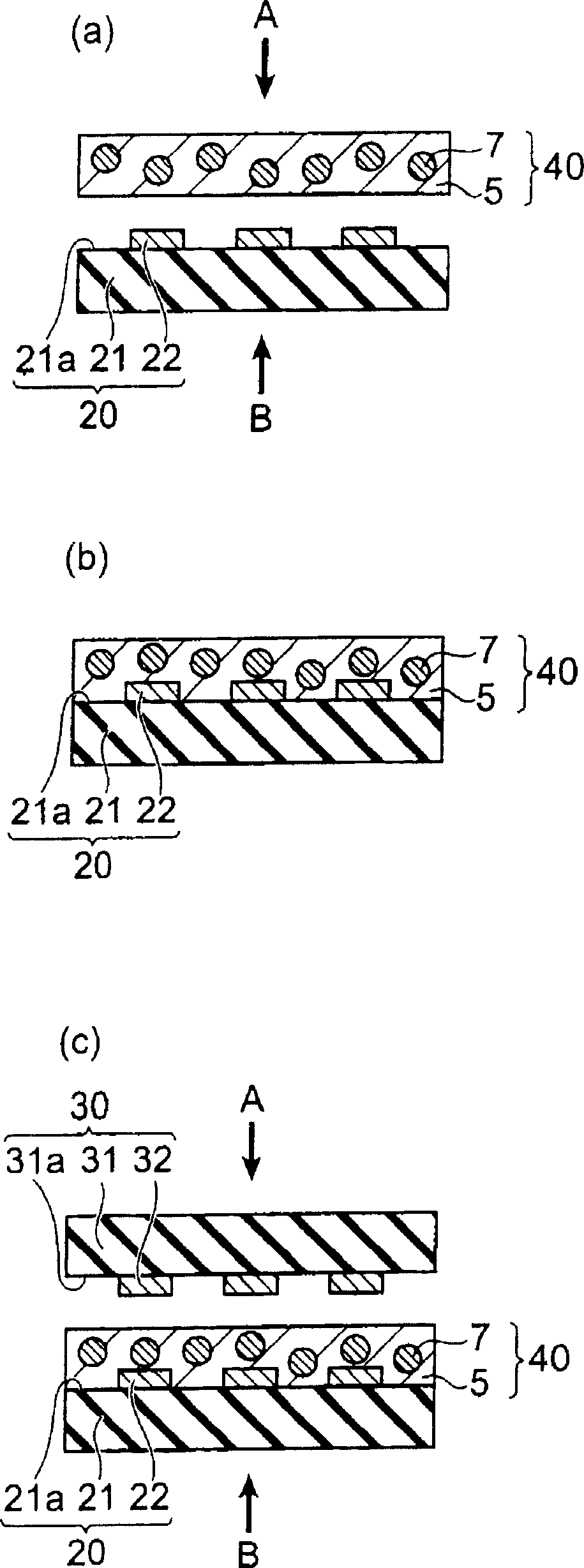

[0097] Circuit connection material

[0098] The circuit connection material of the present embodiment is used for a first circuit member having a first circuit electrode formed on a main surface of a first circuit board and a second circuit member having a second circuit electrode formed on a main surface of a second circuit board. The first circuit electrode and the second circuit electrode are connected in the state of facing each other, including an adhesive composition having a radical polymerizable compound and a radical polymerization initiator, and a conductive material having a surface treated with a compound having a nitrogen-silicon bond. particle.

[0099] First, the adhesive composition contained in the circuit connection material in this embodiment is demonstrated. The adhesive composition contains at least a radical polymerizable compound and a radical polymerization initiator.

[0100] As the radical polymerizable compound and the radical polymerization initia...

Embodiment 1

[0141] Dissolve 50 g of phenoxy resin (manufactured by Union Carbide Co., Ltd., trade name PKHC, average molecular weight 45,000) in toluene (boiling point 110.6°C, SP value 8.90) / ethyl acetate (boiling point 77.1°C, SP value) at a mass ratio of 50 / 50 In the mixed solvent of 9.10), a phenoxy resin solution having a solid content of 40% by mass was obtained.

[0142] As the radical polymerizable compound, hydroxyethylethylene glycol dimethacrylate (manufactured by Kyoeisha Chemical Co., Ltd., trade name 80MFA) and phosphate dimethacrylate (manufactured by Kyoeisha Chemical Co., Ltd., trade name P- 2M).

[0143] As a silazane compound (a compound having a nitrogen-silicon bond), 1,3,5,7-tetraethenyl-1,3,5,7-tetramethylcyclotetrasilazane (manufactured by Chisso Corporation) was used.

[0144] As a radical polymerization initiator, di-2-ethylhexylperoxydicarbonate (manufactured by NOF Corporation, trade name Pa-Roil OPP) was used.

[0145] On the surface of the polystyrene core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com