Fire-proof type exterior wall composite thermal insulation decorative board and manufacture method thereof

A composite thermal insulation and decorative board technology, applied in covering/lining, construction, building structure, etc., can solve the problem of endangering personal life and property safety, without considering the preparation method of fire-proof external wall composite thermal insulation decorative board, long construction period, etc. To achieve the effect of protecting personal life and property safety, controllable quality of prefabrication, and integration of appearance and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

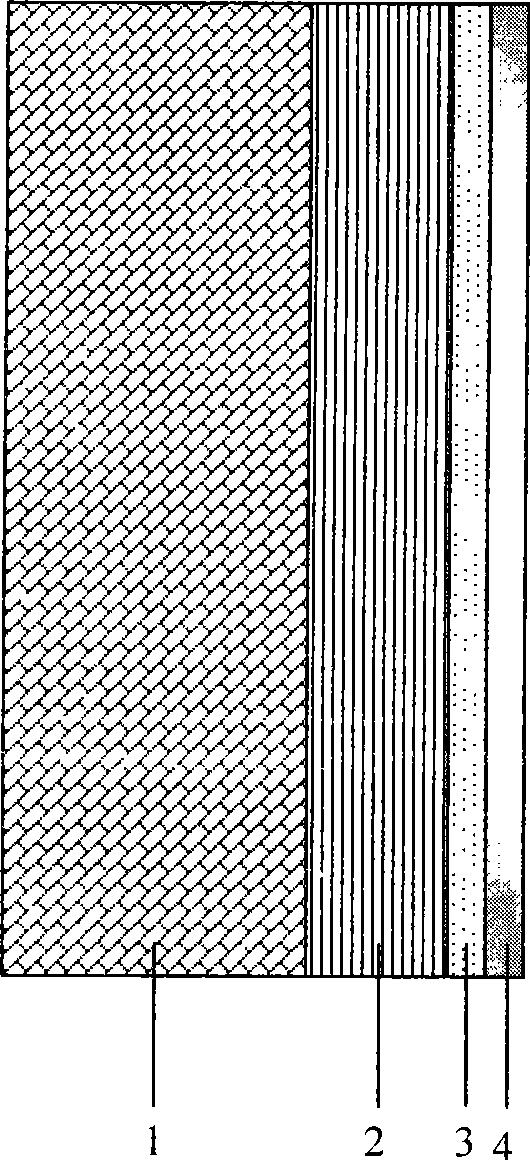

[0027] A method for preparing a fireproof exterior wall composite thermal insulation decorative board, which comprises the following steps:

[0028] 1) Hydrophobicity of the fireproof insulation layer: Process the rock wool to 600mm×600mm×30mm; then use the spraying construction method to cover the surface of the rock wool with silicone water repellent;

[0029] 2) Preparation of the fire-proof and heat-insulating layer: bonding a 3-8 mm thick calcium-silicon board to the above-mentioned rock wool treated with hydrophobic treatment to obtain a fire-proof and heat-preserving layer;

[0030] 3) Preparation of the reinforcing layer: according to the ratio of 300 parts of cement, 600 parts of medium and fine sand, 1.5 parts of dispersible latex powder, 0.3 parts of water retaining agent, 0.3 parts of water reducing agent, 0.1 part of defoaming agent, and 250 parts of water, through a mixer Stir to obtain a polymer mortar. Cover the fireproof insulation layer with 3-8mm thick poly...

Embodiment 2

[0034] A method for preparing a fireproof exterior wall composite thermal insulation decorative board, which comprises the following steps:

[0035] 1) Hydrophobicity of the fireproof insulation layer: Process the mineral wool to 600mm×600mm×50mm; then use the soaking construction method to cover the surface of the rock wool with silicone water repellent;

[0036] 2) Preparation of the fire-proof and heat-insulating layer: bonding a 3-8 mm thick calcium-silicon board to the above-mentioned mineral wool treated with water-repellent treatment to obtain a fire-proof and heat-preserving layer;

[0037] 3) Preparation of reinforcement layer: A 600mm×600mm×3mm thick silicon-calcium board is bonded to the fireproof insulation layer with an acrylic adhesive to obtain a reinforcement layer;

[0038] 4) Preparation of the decorative layer: after bonding the fireproof insulation layer and the reinforcing layer, spray acrylic latex paint on the surface of the reinforcing layer to obtain t...

Embodiment 3

[0041] A method for preparing a fireproof exterior wall composite thermal insulation decorative board, which comprises the following steps:

[0042] 1) Hydrophobicity of the fireproof insulation layer: process the rock wool board to 600mm×600mm×60mm; then use the spraying construction method to cover the surface of the rock wool board with silicone water repellent;

[0043] 2) Preparation of the fire-proof and heat-insulating layer: bonding a 3-8 mm thick calcium-silicon board to the above-mentioned rock wool board that has undergone hydrophobic treatment to obtain a fire-proof and heat-preserving layer;

[0044] 3) Preparation of reinforcement layer: A 600mm×600mm×3mm thick silicon-calcium board is bonded to the fireproof insulation layer with an acrylic adhesive to obtain a reinforcement layer;

[0045] 4) Preparation of the decorative layer: after bonding the fireproof insulation layer and the reinforcing layer, spraying metallic paint on the surface of the reinforcing layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com