Novel composite insulating thin-wall external wall board and manufacturing method thereof

A technology of composite thermal insulation and external wall panels, applied in the direction of building structure, structural elements, building components, etc., can solve the problems of architectural beauty, energy saving and thermal insulation, heat insulation and sound insulation integration, high maintenance costs, poor fire performance, etc. problems, to achieve the effect of good deformation ability, low maintenance cost and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

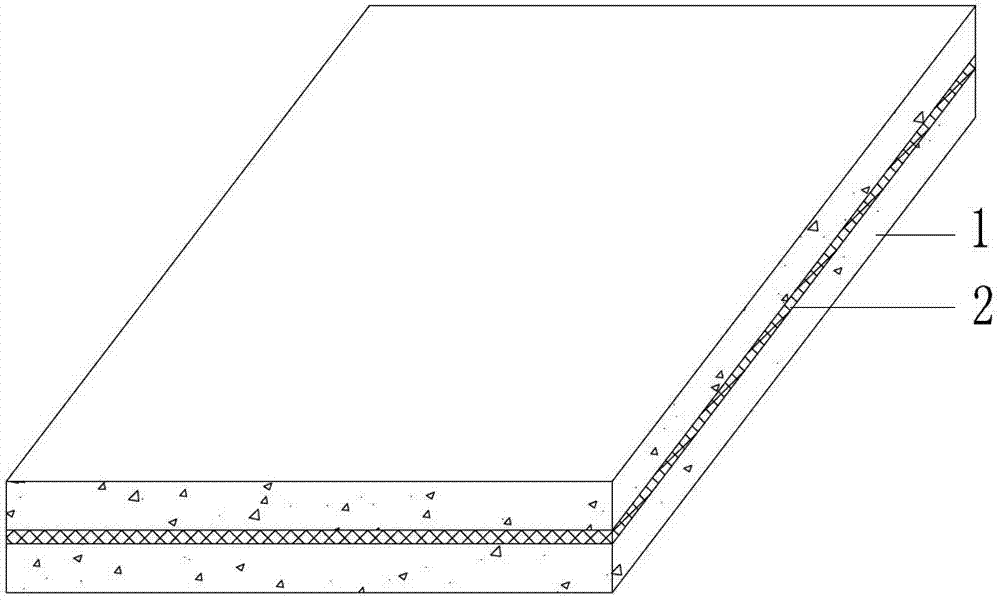

[0022] Embodiment 1, with reference to figure 1 .

[0023] The present invention is mainly composed of fiber braided mesh reinforced concrete and thermal insulation wall materials; wherein, the fiber braided mesh reinforced concrete is composed of high-performance fine concrete 1 and fiber braided mesh 2, and the fiber braided mesh is used as a reinforcing material with high performance fine The mass ratio of each component of the concrete mixture is cement: water: fly ash: silica fume: water reducer: coarse sand: fine sand = 1: (0.45~0.55): (0.3~0.36): (0.05 ~0.1): (0.006~0.01): (0.9~1.0): (1.8~2.0), the particle size range of coarse sand is 0.6~1.2mm; the particle size range of fine sand is less than 0.6mm; the insulation wall material is Nano-silica gel, the thermal insulation material powder is directly mixed into high-performance fine concrete, and the volume dosage is 2-4% of the board composed of fiber braided mesh reinforced concrete.

[0024] A layer of fiber braide...

Embodiment 2

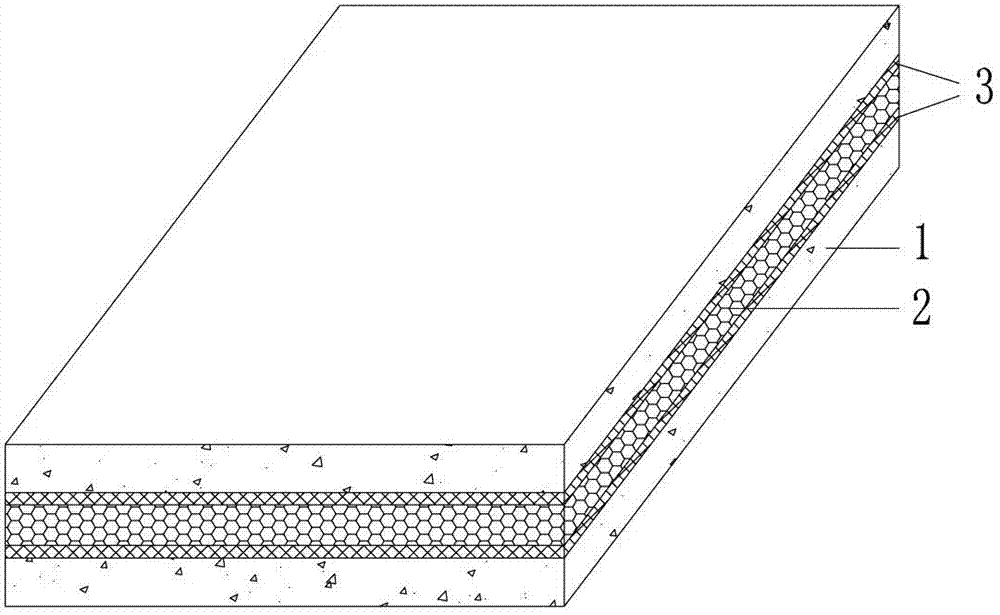

[0026] Embodiment 2, with reference to figure 2 .

[0027]The present invention is mainly composed of fiber braided mesh reinforced concrete and thermal insulation wall materials; wherein, the fiber braided mesh reinforced concrete is composed of high-performance fine concrete 1 and fiber braided mesh 3, and the fiber braided mesh is used as a reinforcing material with high performance fine The mass ratio of each component of the concrete mixture is cement: water: fly ash: silica fume: water reducer: coarse sand: fine sand = 1: (0.45~0.55): (0.3~0.36): (0.05 ~0.1): (0.006~0.01): (0.9~1.0): (1.8~2.0), the particle size range of coarse sand is 0.6~1.2mm; the particle size range of fine sand is less than 0.6mm; the insulation wall material adopts The foam concrete insulation board 2, the combination of the foam concrete insulation board 2 and the fiber braided mesh reinforced concrete is a sandwich composite board, and the foamed concrete insulation board 2 is sandwiched betwee...

Embodiment 3

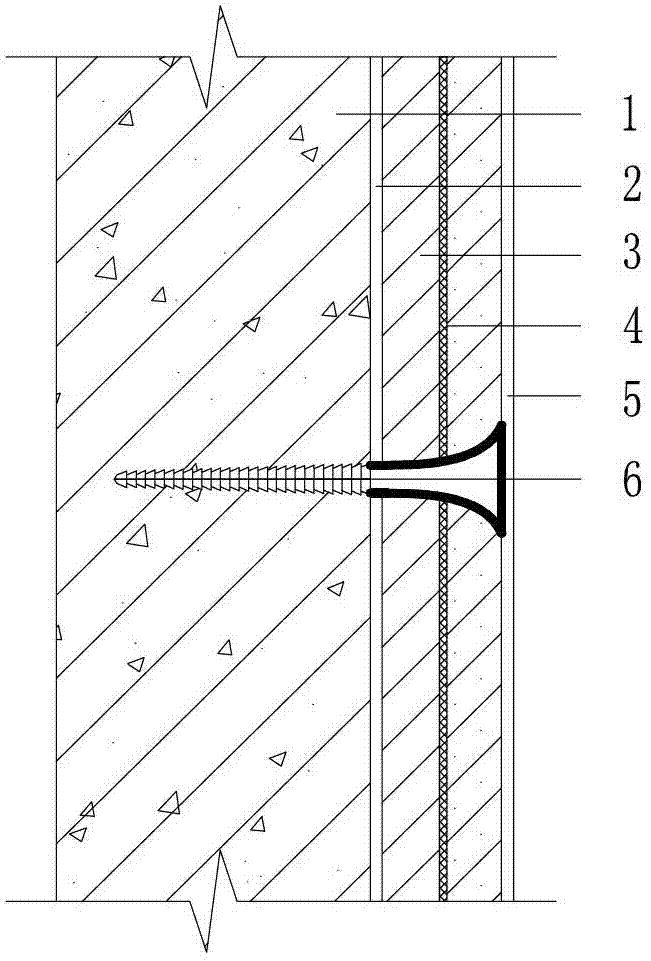

[0030] Embodiment 3, with reference to attached image 3 , 4 .

[0031] The prefabricated exterior wall panels are transported to the construction site by a special vehicle for combined installation. The connection method between the prefabricated exterior wall panels and the structural system can be adopted in the following two ways:

[0032] (1) if image 3 As shown, the connection between the exterior wall panels and the main structure 1 is realized through anchors such as bolts 6, and the wall panels and the structural system are fastened by expansion bolts at intervals, and the gaps between the panels are filled with mortar, and finally the surface of the exterior walls Surface coating 5 is then carried out; wherein the reference number 2 is the interface agent, the reference number 3 is the exterior wall board, and the reference number 4 is the fiber braided net in the exterior wall board.

[0033] (2) if Figure 4 As shown, the external wall panel and the structural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com