Polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy and preparation method thereof

A technology for polyurethane rigid foam and external wall thermal insulation, which is applied in the field of external wall thermal insulation, can solve the problems of conflict between fire and flame retardant properties and mechanical properties, and achieve the effects of excellent mechanical properties and high flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of phosphorus-containing flame-retardant polyether polyol:

[0017] Heat and dissolve 0.2mol tetrabromobisphenol A, 0.5mol pentaerythritol, and 0.3mol sucrose, slowly add 0.3mol polyphosphoric acid and phosphorus pentoxide mixture at 100°C, then react for 5 hours, then drop 10mol epichlorohydrin for ring opening After the etherification reaction, a flame-retardant polyether polyol containing 5 wt% of phosphorus and 10 wt% of bromine is obtained.

[0018] Preparation of component B:

[0019] Bromine with a concentration of 8wt% was added dropwise to polyphenyl polymethyl isocyanate at room temperature, kept at 65° C. for 10 hours, and vacuumed for 1 hour to obtain bromine-containing polyphenyl polymethyl isocyanate.

Embodiment 2

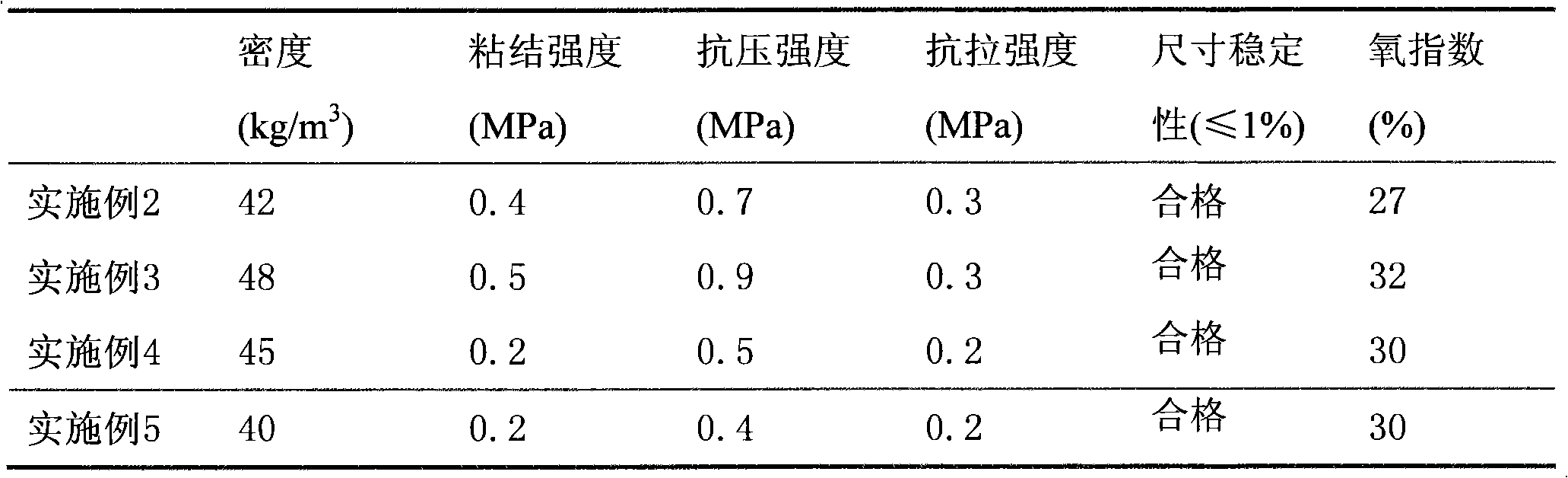

[0021] Use 5g of phenolic resin and 5g of brominated epoxy resin to pre-mix with 90g of phosphorus-containing flame-retardant polyether, add 2g of silicone foam stabilizer, 2g of catalyst dimethylethanolamine, 1g of catalyst dibutyltin dilaurate, and flame retardant A dimethyl phosphate 50g, foaming agent fluorodichloroethane 20g; as component A, polyphenyl polymethyl isocyanate as component B, the weight ratio of component A and component B is 1:1 Mixed foaming, the isocyanate index is 1.05, and the oxygen index of the obtained polyurethane rigid foam is 27.

Embodiment 3

[0023] Use 20g of phenolic resin, 20g of brominated epoxy resin and 60g of phosphorus-containing flame-retardant polyether to pre-mix, add 2g of silicone foam stabilizer, 2g of catalyst dimethylethanolamine, 1g of catalyst dibutyltin dilaurate, flame retardant phosphoric acid Tris (2-chloroethyl) ester 20g, foaming agent fluorodichloroethane 40g; As A component, bromine-containing polyphenyl polymethyl isocyanate is used as B component, A component and B group The parts are mixed and foamed according to the weight ratio of 1:1.5, the isocyanate index is 1.10, and the oxygen index of the obtained polyurethane rigid foam is 32.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com