Water-based fluorocarbon heat insulation coating and preparation method

A thermal insulation, water-based fluorocarbon technology, applied in the field of coatings, can solve the problems of poor stain resistance, no air permeability, peeling of the finish layer, etc., and achieve outstanding heat insulation effect, low thermal conductivity, and low heat storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

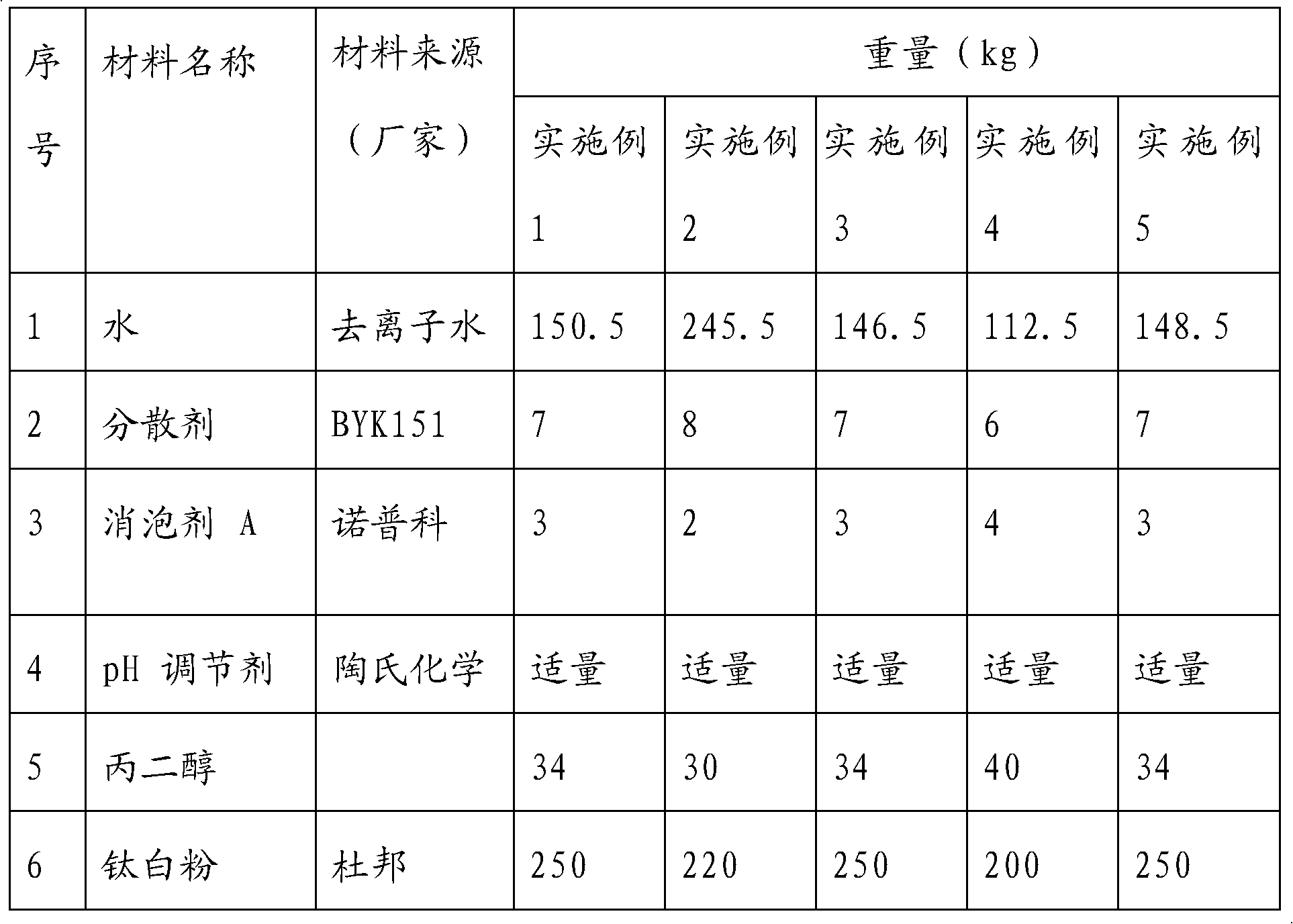

Examples

Embodiment 1

[0031] The water is deionized water, which is the dispersion medium of the whole formula; the water-based fluorocarbon emulsion is a fluorine-modified emulsion with excellent weather resistance, with a solid content of 48-50%, and a fluorine content of 9-10%, which is The coating film provides excellent weather resistance, stain resistance, water resistance, alkali resistance and enhanced adhesion, and is also one of the base materials for coatings.

[0032] The dispersant is an anionic polyfunctional polymer alcohol amine salt solution, which can increase the gloss and fullness of the coating film, reduce the viscosity and improve the wetting effect of the pigment; improve the storage stability and workability of the coating, and does not contain alkane phenol ethoxylates.

[0033] The titanium dioxide is imported rutile titanium dioxide, which has high refractive index and high whiteness, can produce high refraction and reflection to sunlight, and has good weather resistance...

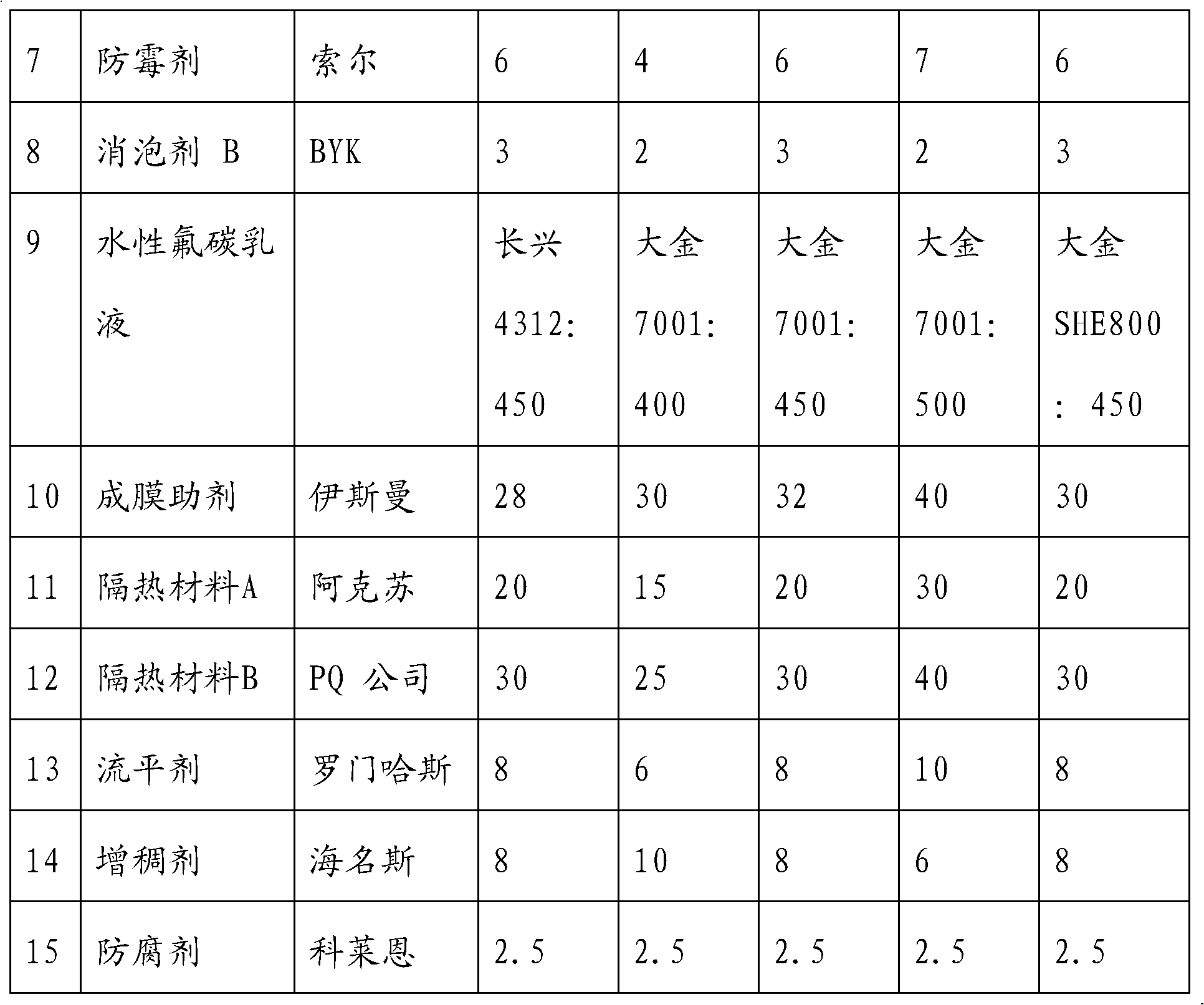

Embodiment 2

[0046] The difference from Example 1 is that the main film-forming material water-based fluorocarbon emulsion is of different types. In this example, vinylidene fluoride (VDF) copolymer and polymethyl methacrylate (PMMA) are used at the molecular level. The mixture of the PMMA ester group and the PVDF unit interacts strongly, so that the ester group can be protected by PVDF, so the coating film has good water resistance and excellent weather resistance; and its fluorine content is ≥ 18%, and the solid content is 50±1%; the minimum film-forming temperature is 32°C; the glass transition temperature is about 29°C, and the average particle size is 200nm. The rest of the materials used are the same as in Example 1, only the amount used is different, so no more details are given here.

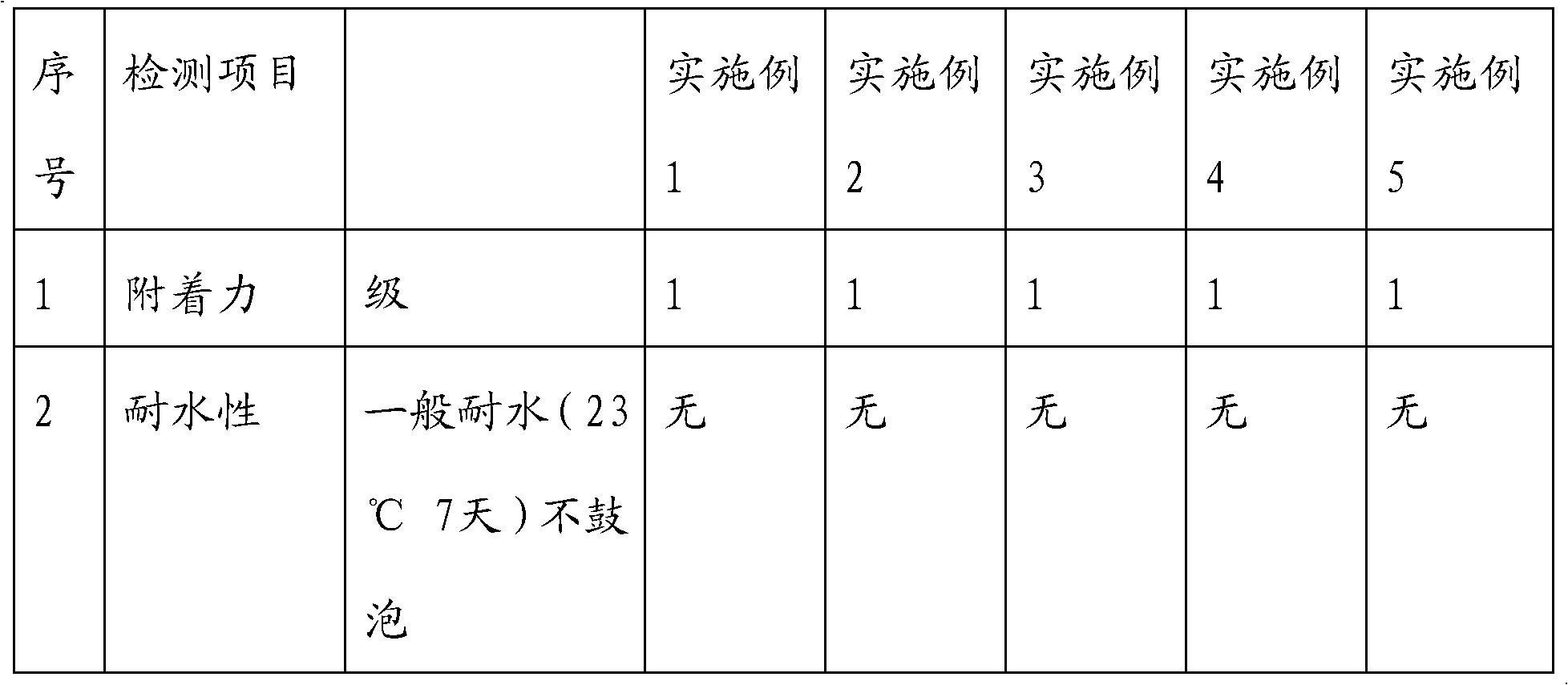

[0047]The quality and technical indicators of the coating film obtained by the above-mentioned embodiment 2 component distribution ratio and preparation method are shown in Table 2.

[0048] The mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com