Method and special equipment for preparing unidirectionally-distributed steel fiber reinforced concrete

A technology of steel fiber reinforced concrete and reinforced concrete, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of low effective utilization efficiency of steel fibers and increased raw material costs, and achieves increased raw material costs, improved flexural strength, and tensile strength. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

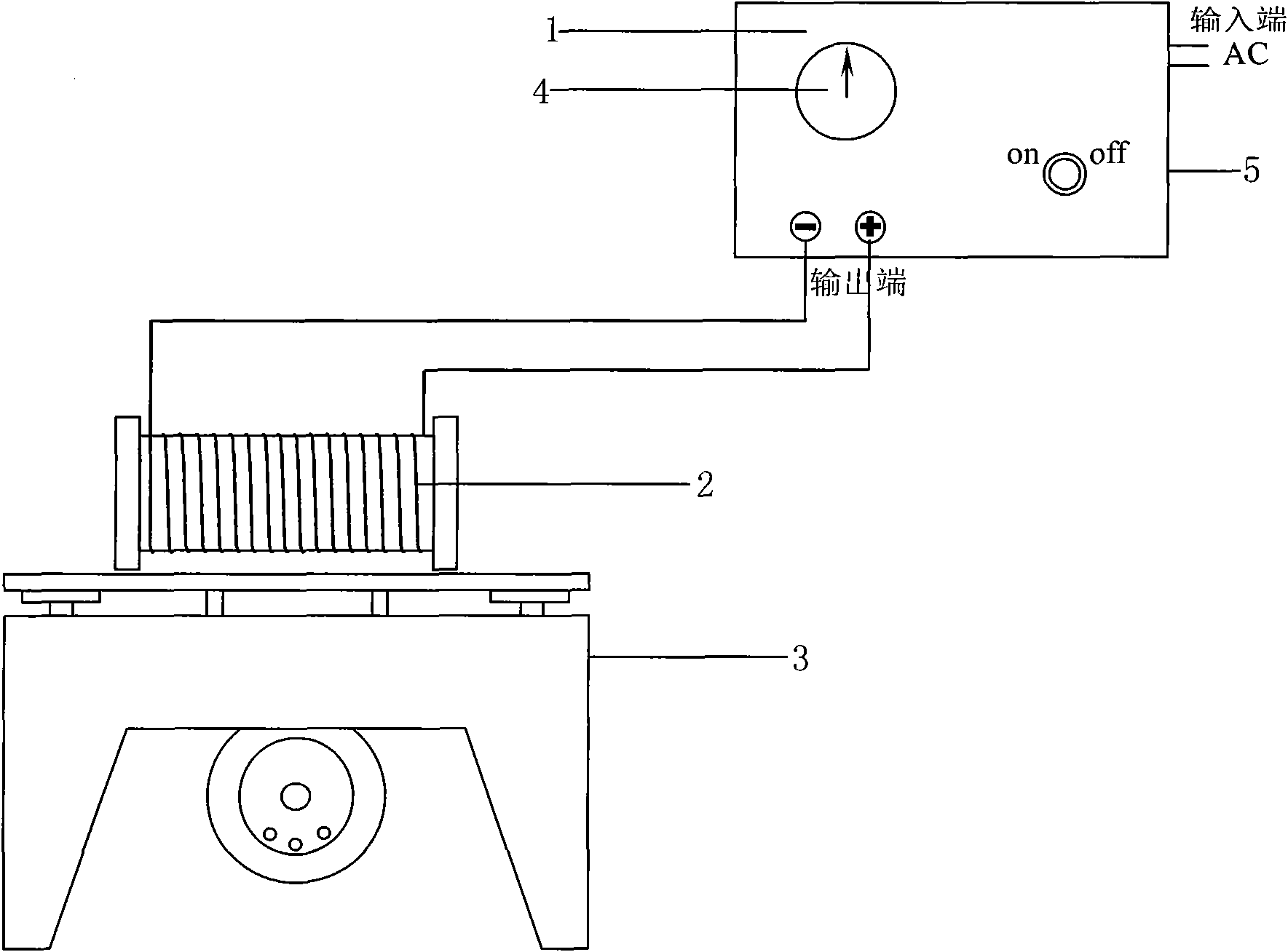

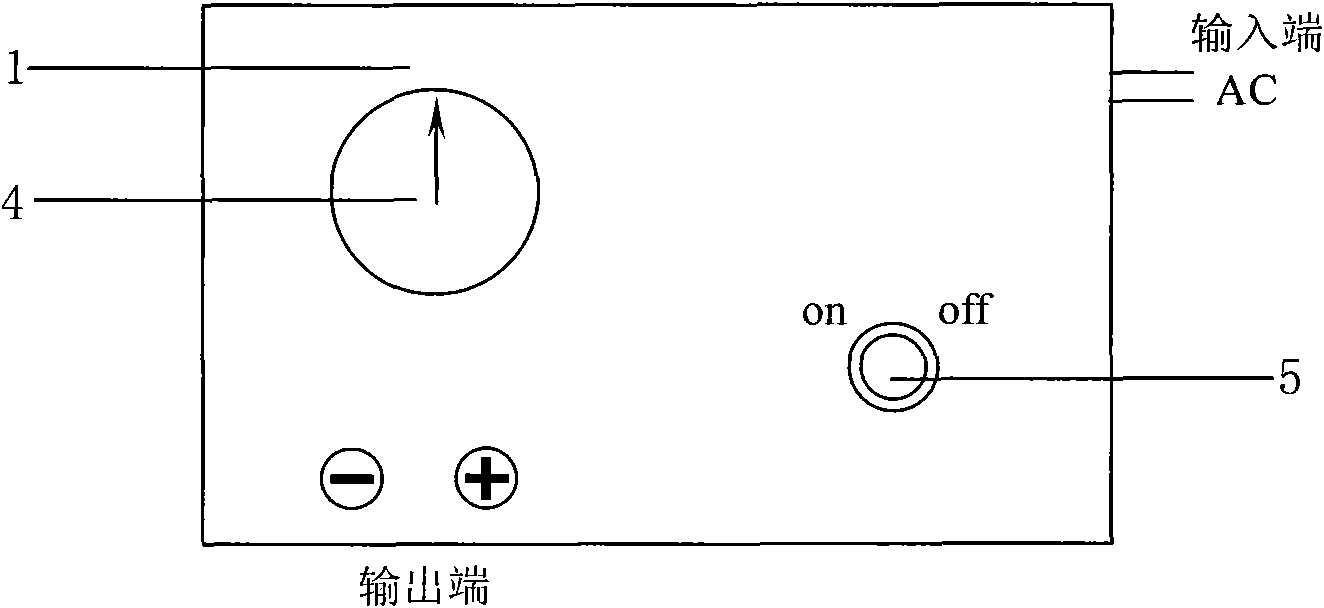

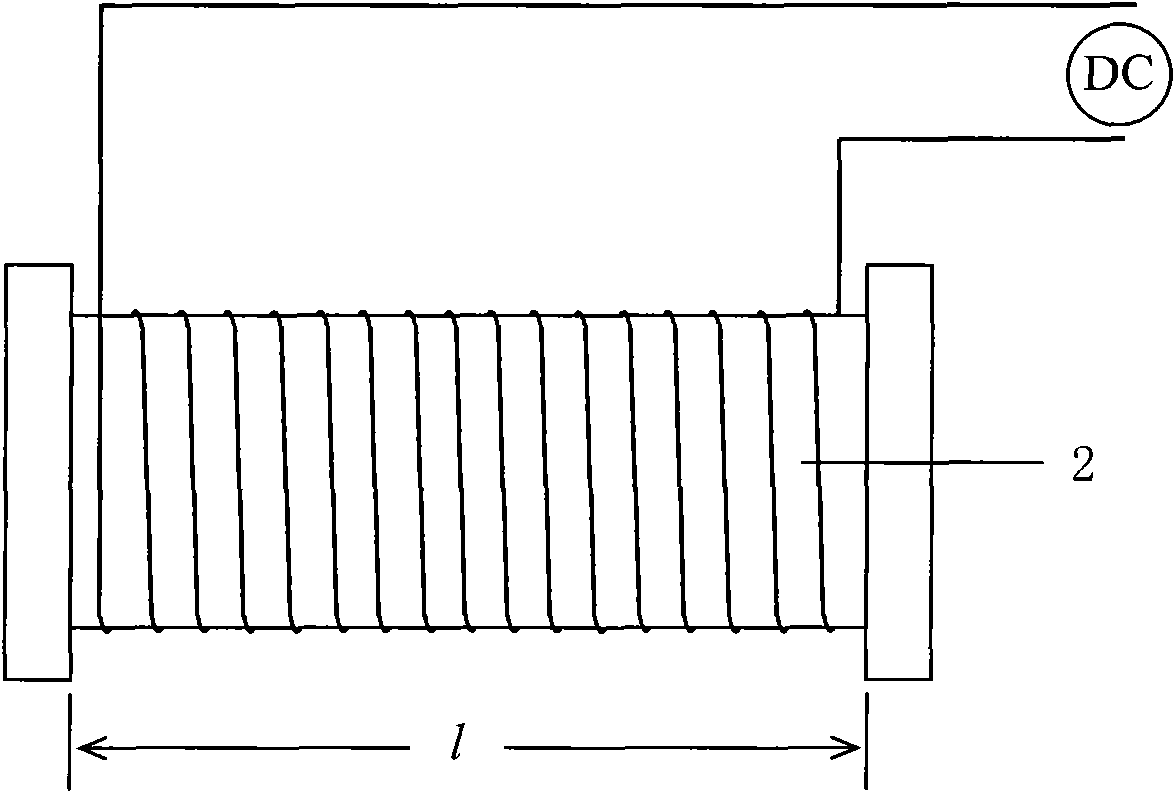

Method used

Image

Examples

Embodiment 1

[0044] The first step is to prepare the steel fiber concrete mixture

[0045] According to the known design method, the mass ratio of the concrete components whose strength grade is C40 is water: cement: fly ash: sand: stone: high-efficiency water reducer: steel fiber = 180: 375: 75: 780: 990:2.2:47 Weigh the required amount of water, cement, fly ash, sand, stone, high-efficiency water reducer and steel fiber. The steel fiber used is made of low carbon steel by cutting technology, with a diameter of 0.5mm and a length of The diameter ratio is 40. Put the weighed cement, fly ash, sand and stone into the dry material of the mixer and mix evenly, then put in all the weighed steel fibers while stirring until evenly mixed, then add the weighed mixing water and high-efficiency water reducing agent, continue to stir for 90 seconds, and the slump of the concrete mixture is 160mm;

[0046] The second step, pouring into the test mold

[0047] Pour the steel fiber concrete mixture pre...

Embodiment 2

[0057] The first step is to prepare the steel fiber concrete mixture

[0058] According to the known design method, the mass ratio of the concrete components whose strength grade is C55 is water: cement: fly ash: sand: stone: superplasticizer: steel fiber=170:385:95:775: 980:3.0:117 Weigh the required amount of water, cement, fly ash, sand, stone, high-efficiency water reducer and steel fiber, the steel fiber used is made of low carbon steel material by cutting technology, with a diameter of 0.5mm and a length of The diameter ratio is 40. Put the weighed cement, fly ash, sand and stone into the dry material of the mixer and mix evenly, then put in all the weighed steel fibers while stirring until evenly mixed, then add the weighed mixing water and high-efficiency water reducing agent, continue stirring for 300 seconds, and the slump of the concrete mixture is 40mm;

[0059] The second step, pouring into the test mold

[0060] Pour the steel fiber concrete mixture prepared i...

Embodiment 3

[0070] The first step is to prepare the steel fiber concrete mixture

[0071] According to the known design method, the mass ratio of the concrete components whose strength grade is C45 is water: cement: fly ash: sand: stone: superplasticizer: steel fiber=165:430:0:815: 970:3.2:59 Weigh the required amount of water, cement, fly ash, sand, stone, high-efficiency water reducer and steel fiber, the steel fiber used is made of low carbon steel material by cutting technology, with a diameter of 0.5mm and a length of The diameter ratio is 40. Put the weighed cement, fly ash, sand and stone into the dry material of the mixer and mix evenly, then put in all the weighed steel fibers while stirring until evenly mixed, then add the weighed mixing water and high-efficiency water reducing agent, continue to stir for 180 seconds, and the slump of the concrete mixture is 135mm;

[0072] The second step, pouring into the test mold

[0073] Pour the steel fiber concrete mixture prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com