Preparation method and application of nano glass fiber reinforced concrete material

A technology of nano-glass fiber and reinforced concrete, which is applied in the field of concrete materials, and can solve the problems of inconvenient production process, increased component cost, and decreased productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

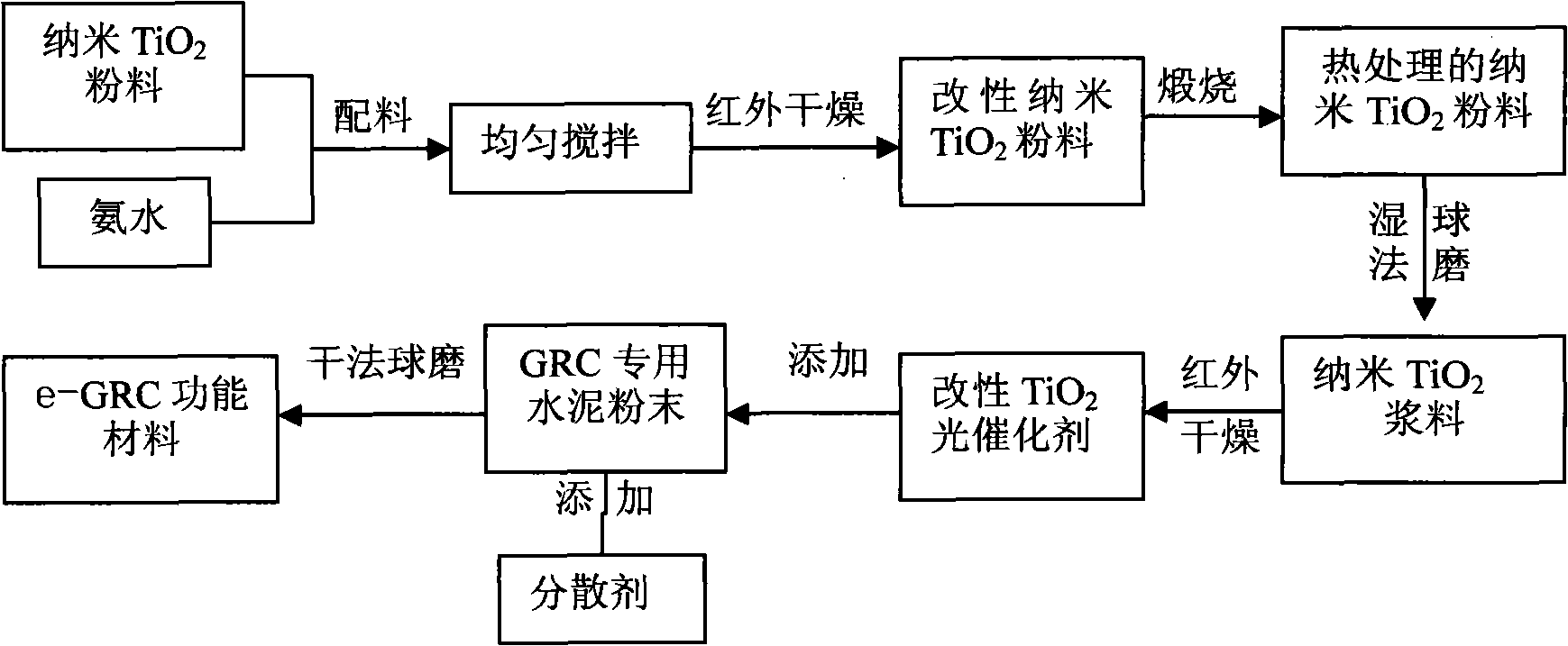

[0026] A preparation method of nano glass fiber reinforced concrete material (e-GRC functional material) with self-cleaning function, see figure 1 , the method includes the following steps:

[0027] 1) Selection and modification of nano-titanium dioxide; nano-titanium dioxide is mixed with rutile type and anatase type in a weight ratio of 50 to 30; the particle size of nano-titanium dioxide is between 10-20 nanometers, and the nano-titanium dioxide powder is heat-treated. Calcining at 500°C for 2 hours, adding non-metallic ion N modified titanium dioxide to obtain modified nano titanium dioxide powder;

[0028] 2) Dispersion of nano-titanium dioxide; multi-stage dispersion process is adopted; first, the modified nano-titanium dioxide after heat treatment uses zirconia balls as the grinding medium, and performs primary dispersion through wet ball milling to reduce the powder agglomeration phenomenon caused by heat treatment, and obtain nano Titanium dioxide slurry;

[0029] 3...

Embodiment 2

[0032] Another preparation method of nano glass fiber reinforced concrete material (e-GRC functional material) with self-cleaning function. Compared with Example 1, the method differs in that the nano-titanium dioxide is rutile type and anatase type by 20~ Mixing ratio of 25; the particle size of nano-titanium dioxide is between 5-10 nanometers, and calcined at 400 ° C for 2 hours. Dispersant weight percent 0.5%. The dispersant is acrylate.

Embodiment 3

[0034] Another preparation method of nano glass fiber reinforced concrete material (e-GRC functional material) with self-cleaning function, compared with Examples 1 and 2, the difference is that nano-titanium dioxide is rutile type and anatase type according to 80-75 ratio mixing; the particle size of nano-titanium dioxide is between 20-30 nanometers, and calcined at 600 ° C for 1 hour. The percentage by weight of the dispersant is 1%. The dispersing agent is polyethylene glycol.

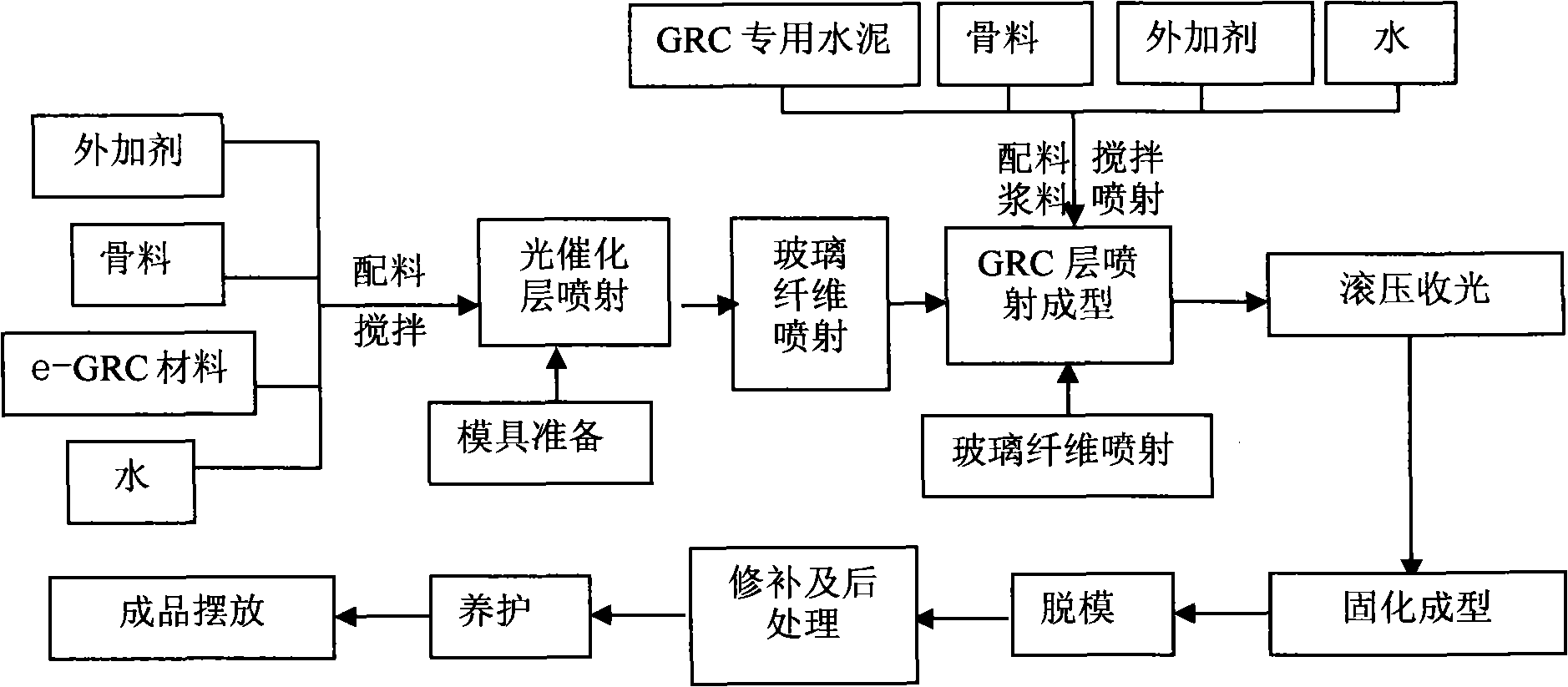

[0035] The application of the nano glass fiber reinforced concrete material that a kind of above-mentioned preparation method obtains in building, see figure 2 , first prepare the nano-concrete slurry without glass fiber, and spray the extremely thin mist layer of the nano-concrete slurry without glass fiber into the mold to obtain a photocatalytic cement coating; then the reinforced cement material containing glass fiber It is sprayed out, mixed and sprayed with GRC special cement slurry, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com