140 MPa grade cold rolled ultra-low carbon steel with high bake hardening characteristic and production method

A technology of bake-hardening and ultra-low carbon steel, which is applied in the production field of 140MPa high-bake-hardening cold-rolled ultra-low-carbon steel and can solve the problems of high forming ability requirements, difficult forming, and small application range, and achieves The effect of high bake hardening value, good formability and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1~10

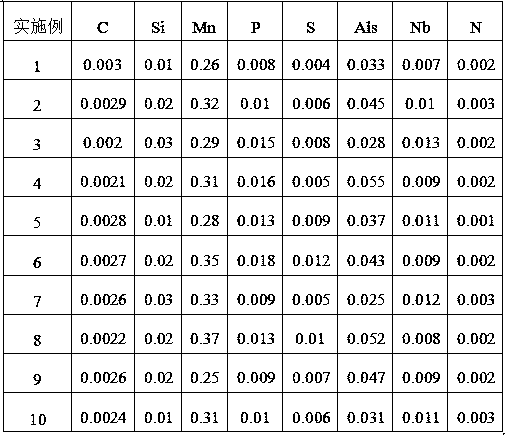

[0029] Below in conjunction with specific embodiment 1~10, the present invention is described in further detail:

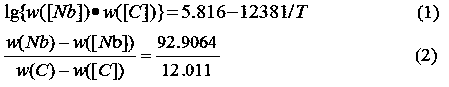

[0030] The chemical composition and mass percentage content of Examples 1-10 are shown in Table 1; the mechanical properties of the bake-hardened steel produced in Examples 1-10 are shown in Table 2. The production method comprises a steelmaking process, a hot rolling process, an acid rolling process and a continuous annealing process; the production process parameters of each embodiment are described as follows:

Embodiment 1

[0032]Hot rolling process: the hot-rolled slab stays in the furnace for 200 minutes, the temperature is 1215°C, the final rolling temperature is controlled at 909°C, the laminar flow cooling is adopted in the front 1 / 2 cooling method, and the coiling temperature is controlled at 710°C;

[0033] Acid rolling process: the total reduction rate of acid rolling is 70%;

[0034] Continuous annealing process: divided into preheating section, heating section 1, heating section 2, heating section 3, soaking section, slow cooling section, fast cooling section, aging section and final cooling section: heating section 3, soaking section temperature control at 850°C, holding time 75s, slow cooling temperature 640°C, slow cooling section cooling speed 10°C / s, fast cooling section end temperature 353°C, fast cooling section cooling speed 59.8°C / s, overaging end temperature 291°C, The aging time is 275s, and the flat elongation rate is 1.0%.

Embodiment 2

[0036] Hot rolling process: the hot-rolled slab stays in the furnace for 216 minutes, the temperature is 1195°C, the final rolling temperature is controlled at 906°C, the laminar flow cooling adopts the front 1 / 2 cooling method, and the coiling temperature is controlled at 703°C;

[0037] Acid rolling process: the total reduction rate of acid rolling is 76%;

[0038] Continuous annealing process: divided into preheating section, heating section 1, heating section 2, heating section 3, soaking section, slow cooling section, fast cooling section, aging section and final cooling section: heating section 3, soaking section temperature control at 845°C, holding time 88s, slow cooling temperature 646°C, slow cooling section cooling speed 7.7°C / s, fast cooling section end temperature 330°C, fast cooling section cooling speed 46°C / s, overaging end temperature 307°C, The aging time is 325s, and the flat elongation rate is 1.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com