Composite forming mold with self-provided pressure source and heat source and mold unit

A forming mold with its own pressure technology, which is applied in the field of composite material forming, can solve the problems of low production efficiency, complicated operation and high cost, and achieve the effects of reduced production cost, simple equipment operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

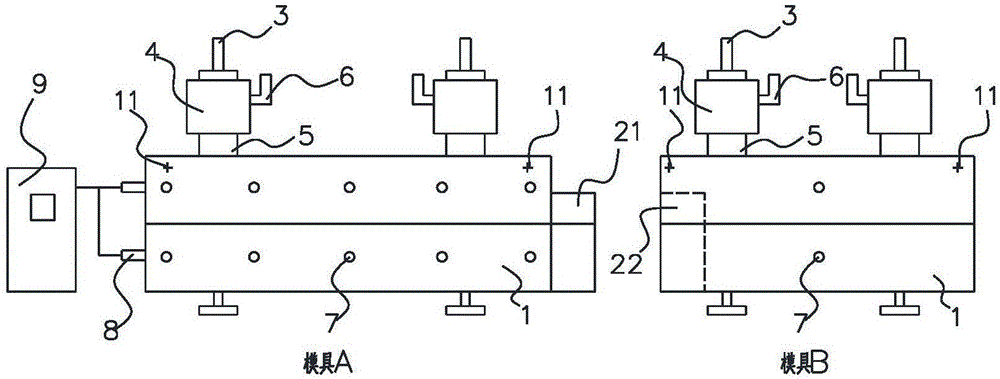

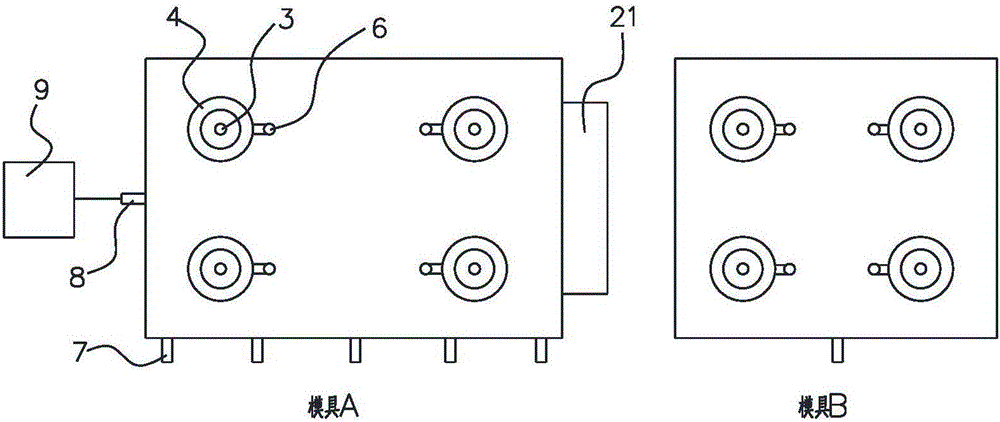

[0023] Such as figure 1 , figure 2 As shown, this embodiment provides a composite material forming mold with its own pressure source and heating source, including mold body 1, pressure source 4, heating source 7 and other components, and pressure source 4 is connected to mold body 1 through force guiding coupling device 3 , the force guiding coupling device 3 runs through the upper and lower surfaces of the mold body 1, and the heating source 7 is connected to the inside of the mold body 1 through the side of the mold body 1 through a thermal pipeline, wherein the pressure source 4 can be an air pressure source or a hydraulic source or a mechanical Pressure source, heating source 7 can choose oil bath source or electric heating source. The pressure source 4 pressurizes the mold body 1 through the force-guiding coupling device 3 to exert pressure on the laminated composite material in the mold body 1 . In this embodiment, there can be multiple pressure sources 4, and multipl...

Embodiment 2

[0026] Such as figure 1 , figure 2 As shown, the present invention also provides a composite material molding die set with its own pressure source and heating source, including a plurality of composite material molding dies with its own pressure source and heating source in Example 1, and the sides of the mold body 1 One side is provided with a locking groove 22 , and the other side of the side of the mold body 1 is provided with a locking block 21 engaged with the locking groove 22 . A plurality of composite molding molds with their own pressure sources and heating sources are combined into a large mold through the slot 22 and the block 21 to meet the molding requirements of various composite material parts, especially for super large composite materials. Forming requirements of parts. It should be noted that the mold cavities of mold A, mold B, mold C... (only mold A and mold B are shown in the figure) are interconnected, and can be sealed through the lap groove 22 and bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com