Special device for manufacturing composite material molded arc mold release film

A special equipment and release film technology, which is applied in the field of special equipment for manufacturing composite forming arc release films, can solve the problems of uneven thickness, high cost, easy air leakage, etc., and achieve uniform thickness of air bags and high production efficiency. High and air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

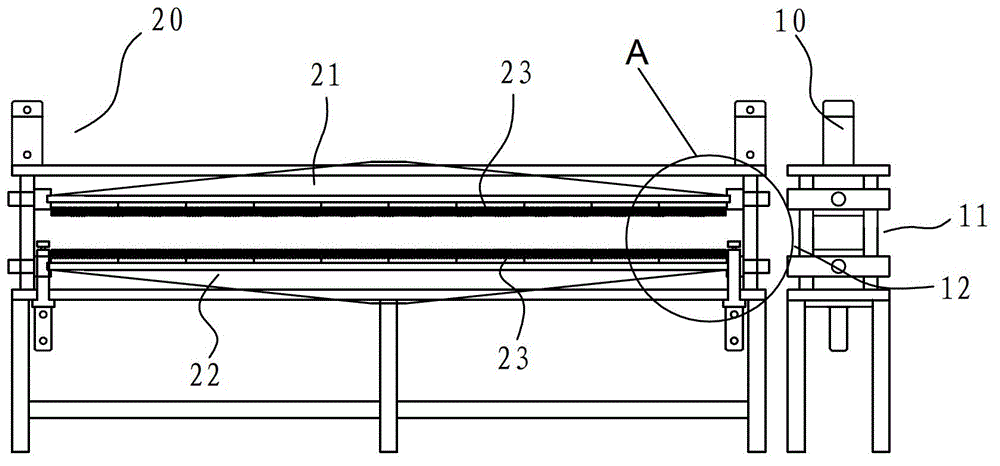

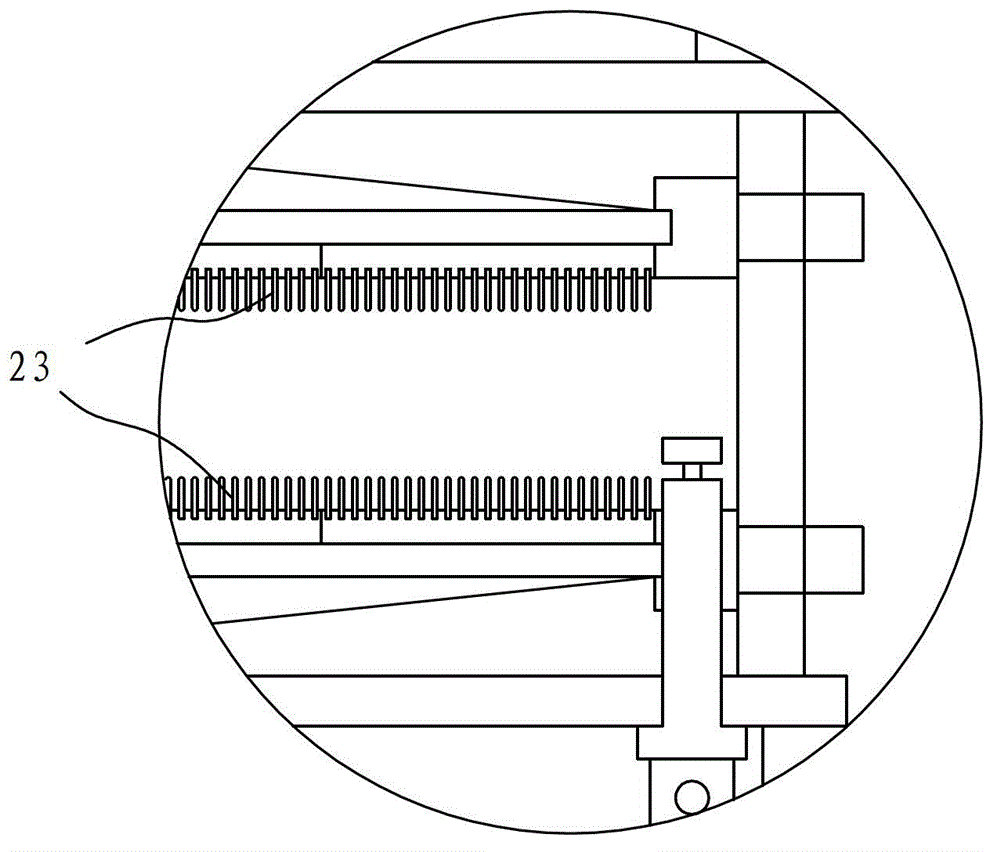

[0011] Such as figure 1 and figure 2 As shown, the special equipment for manufacturing arc-shaped release film for composite material forming according to the present invention includes a feed frame 10 and upper and lower welding molds 20 . The feeding frame 10 is provided with a feed port 11 and a discharge port 12, and the discharge port 12 is facing the upper and lower welding molds 20, and the upper and lower welding molds 20 include a patrix 21 and a lower die 22, and the upper die 21 and the lower die The mold 22 is provided with evenly distributed welding contact knives 23, and the welding contact knives 23 on the upper mold 21 and the lower mold 22 are in contact with each other. The outer ends of the welding contact knives 23 are arc-shaped. state.

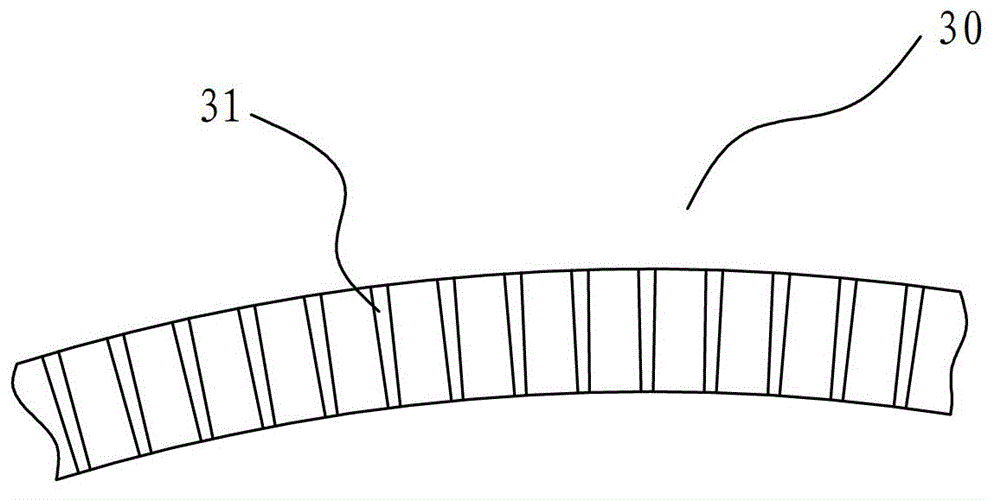

[0012] Such as Figure 1 to Figure 3 As shown, in the actual use process, after the release film 30 enters from the feed port 11 of the feed frame 10, it is pushed into the upper and lower welding molds 20 from the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com