Fiber reinforced concrete stone panel system

a fiber reinforced concrete and panel system technology, applied in the wall field, can solve the problems of inability to see the underlying structure, difficulty in constructing the underlying structure, and substantial skill in the process of attaching paper, screen and mortar to the sheathing of a conventional building, and achieve the effect of reducing construction costs and removing much of the room for error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

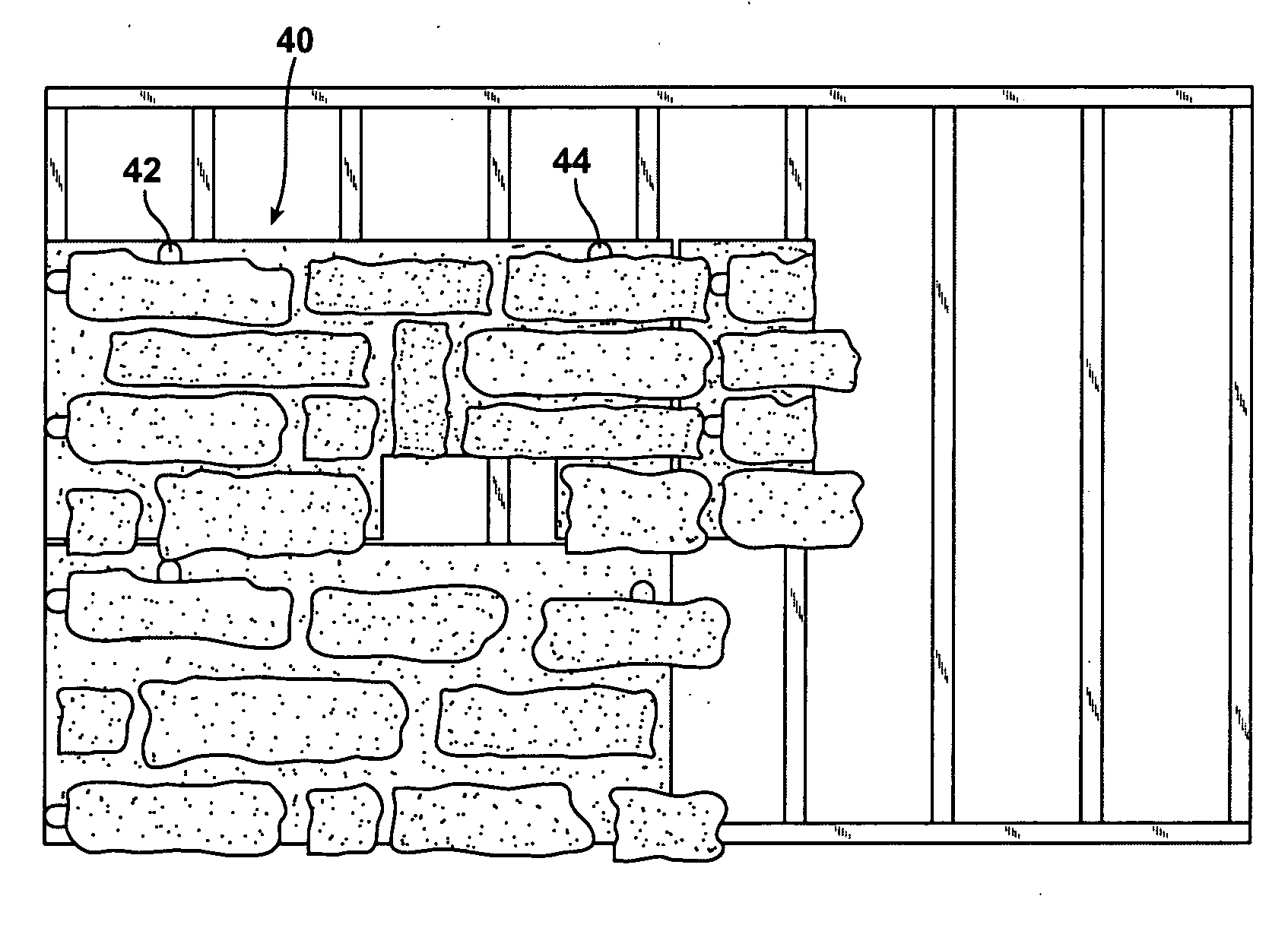

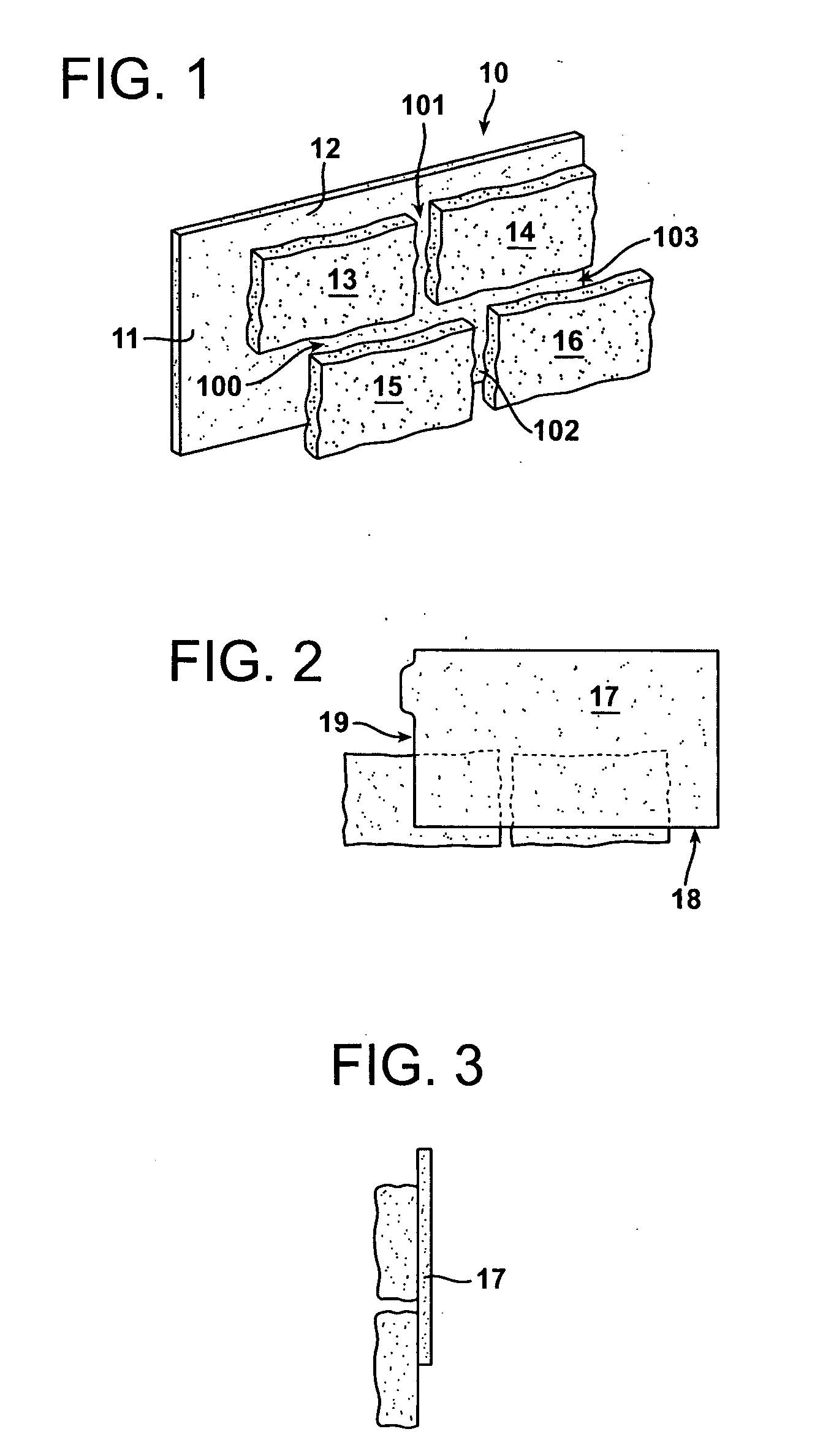

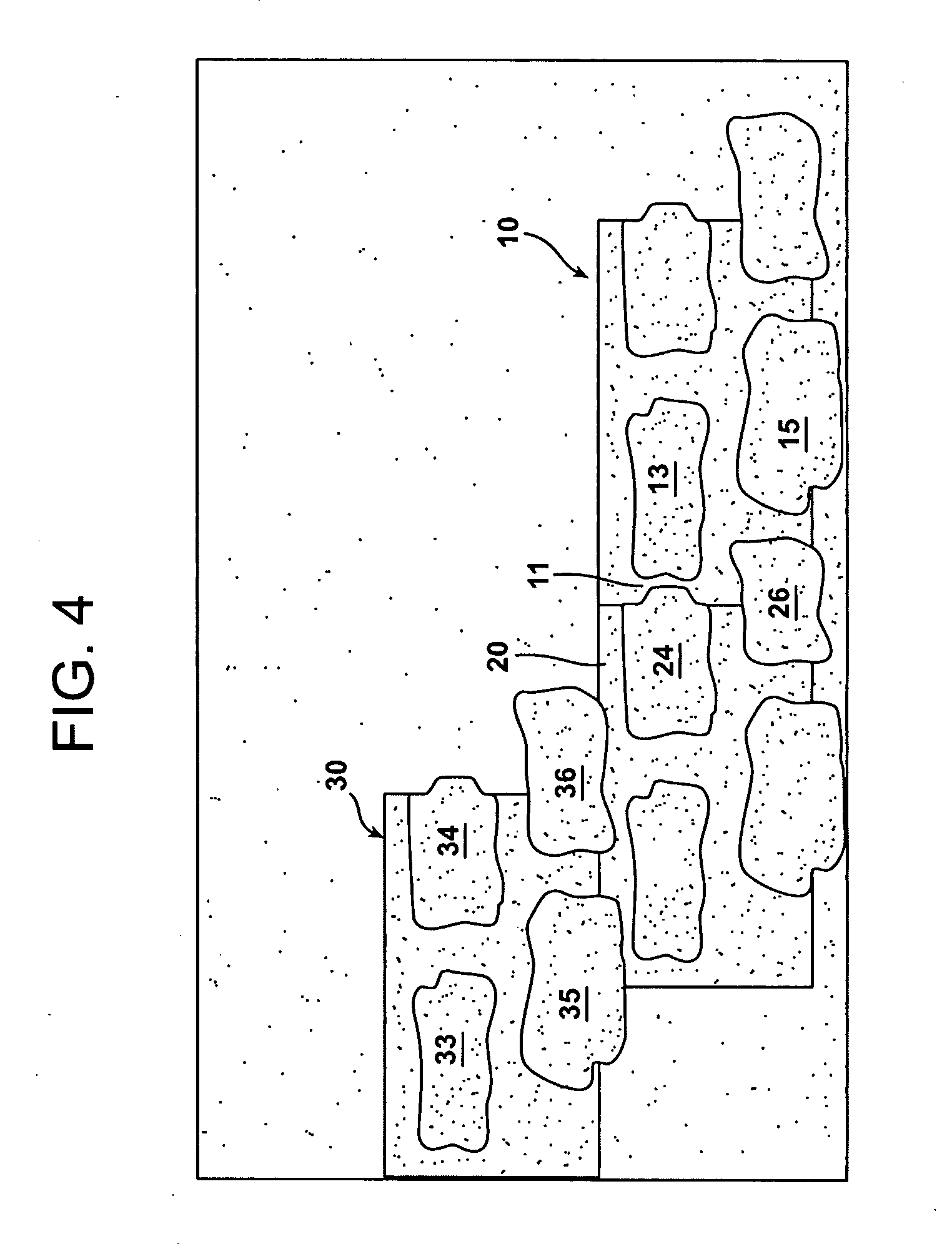

[0029]The panel 10 in FIG. 1 is preferably a single body with one or more masonry units, such as simulated stones 13, 14, 15 and 16 protruding from a rear plate 17. A “masonry unit” is defined herein to be any module that is commonly used to form a weather-resistant surface on a building exterior, and is typically attached by adhesive or mortar with other similar modules, which are then typically grouted in place by injecting mortar between the modules. For the sake of this description, “injecting” includes any manner of placing the mortar into the joints, such as with a grout bag, trowel, or other known manner. The stones 13-16 are not the only size or shape of masonry unit possible on the invention, but are merely exemplary of a common masonry unit: the stone. Other masonry units can be formed on the face of a panel, including bricks and tiles, and other shapes, sizes and colors of stones are contemplated than those shown. Any masonry unit that is commonly mounted to the exterior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com