High-stiffness composite tube formed through fixed length winding and manufacturing method thereof

A winding forming, high rigidity technology, applied in the direction of rigid pipes, ceramic molding machines, chemical instruments and methods, etc., can solve the problems of high construction requirements, inconvenient construction and transportation, high cost of matrix material resin, etc., and achieve excellent corrosion resistance and hydraulic strength performance, good economic performance, and solve the effect of low stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] According to the above preparation process steps, the following process parameters are used for preparation:

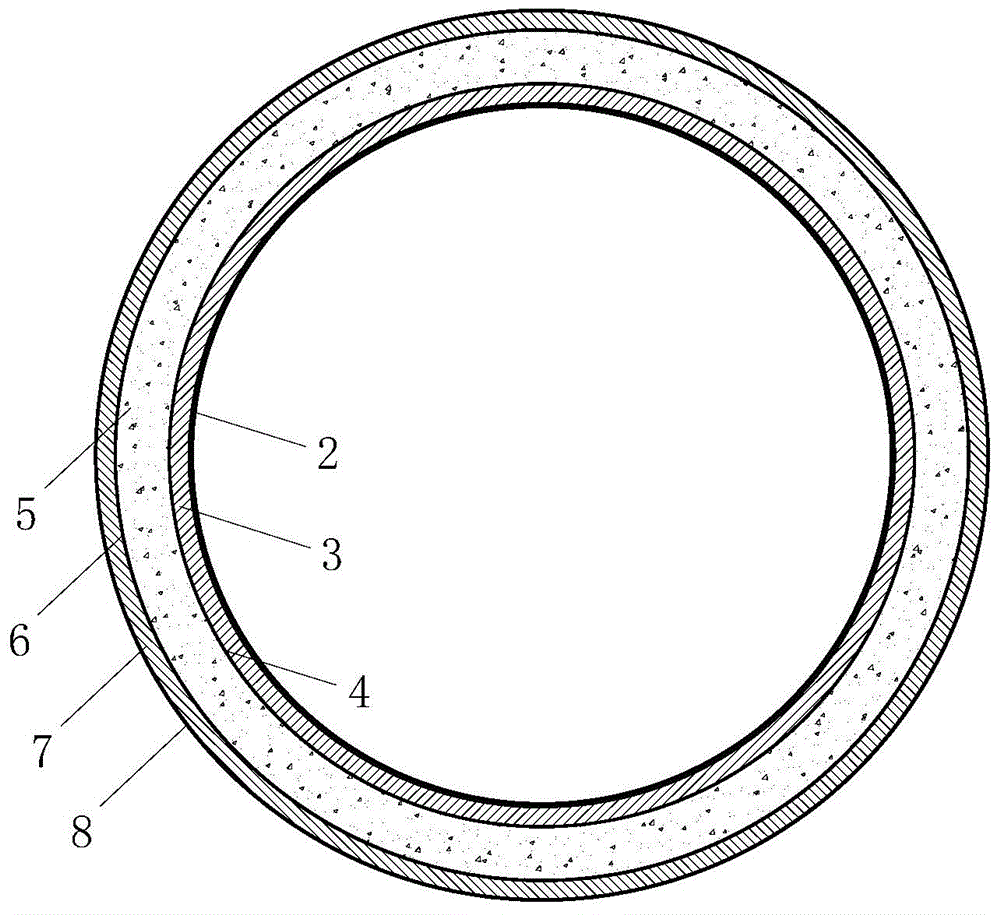

[0045] The inner lining layer has a resin content of 65wt% and is reinforced with glass fiber surface mat and knitted mat, with a thickness of 1.2mm;

[0046] The inner structure layer and the outer structure layer have a resin content of 25wt% and are reinforced with continuous glass fiber yarns, with a thickness of 0.3 mm; the outer structure layer exerts tension on the continuous glass fiber yarns during the winding molding process, and the size is the strength of the continuous glass fiber yarns 1%;

[0047] The outer protective layer has a resin content of 90wt% and is reinforced with glass fiber surface mat, with a thickness of 0.15mm;

[0048] The middle structural layer is PVA fiber concrete cement-based composite material, the fiber content is 1wt%, and the thickness is 20mm;

[0049] The interface adaptation layer is Record's 2 The mixture of two-...

Embodiment 2

[0052] According to the above preparation process steps, the following process parameters are used for preparation:

[0053] The inner lining layer has a resin content of 90wt% and is reinforced with glass fiber surface mat and knitted mat, with a thickness of 5mm;

[0054] The inner structure layer and the outer structure layer have a resin content of 35wt% and are reinforced with continuous glass fiber yarns, with a thickness of 30 mm respectively; the outer structure layer exerts tension on the continuous glass fiber yarns during the winding molding process, and the size is 100% of the strength of the continuous glass fiber yarns. 50%;

[0055] The resin content of the outer protective layer is 95wt% and reinforced with glass fiber surface mat, with a thickness of 2mm;

[0056] The middle structural layer is a glass fiber concrete cement-based composite material, the fiber content is 5wt%, and the thickness is 100mm;

[0057] The interface adaptation layer is Record's 2...

Embodiment 3

[0060] According to the above preparation process steps, the following process parameters are used for preparation:

[0061] The inner lining layer has a resin content of 80wt% and is reinforced with glass fiber surface mat and knitted mat, with a thickness of 3mm;

[0062] The inner structure layer and the outer structure layer have a resin content of 30wt% and are reinforced with continuous glass fiber yarns, with a thickness of 15mm respectively; the outer structure layer exerts tension on the glass fiber surface mat during the winding molding process, and the size is 1% of the strength of the glass fiber surface mat. 25%;

[0063] The outer protective layer has a resin content of 92wt% and is reinforced with glass fiber surface mat, with a thickness of 1mm;

[0064] The middle structural layer is steel fiber concrete cement-based composite material, the fiber content is 3wt%, and the thickness is 50mm;

[0065] The interface adaptation layer is Record's 2 The mixture o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com