Fiber reinforced concrete uplift pile

A technology of concrete piles and fiber reinforcement, which is applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problem that the bonding performance of FRP fibers and concrete is not very mature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

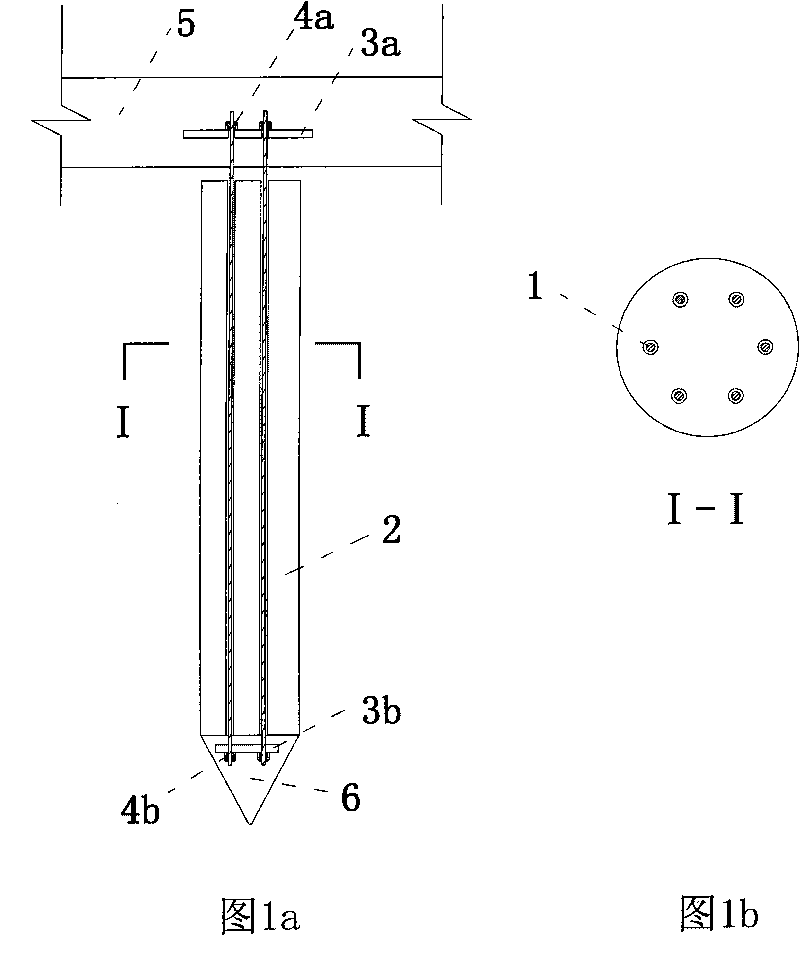

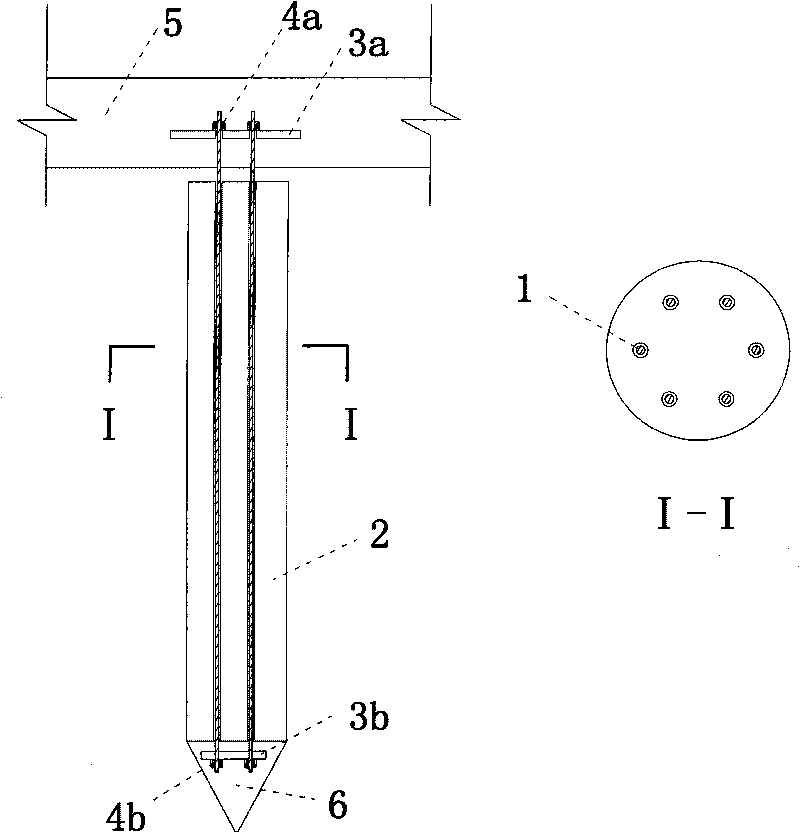

[0016] A fiber-reinforced concrete uplift pile, comprising: a concrete pile body 2, a pile head 6 is arranged on one end of the concrete pile body 2, and an FRP fiber reinforcement 1 with an external sleeve sleeve is arranged inside the concrete pile body 2 And one end of the FRP fiber reinforcement 1 extends into the pile head 6, and the other end of the FRP fiber reinforcement 1 extends out of the concrete pile body 2 in reverse; a second support plate 3b is provided in the pile head 6, located at One end of the FRP fiber reinforcement 1 in the pile head 6 is fixed on the second support plate 3b by the second anchor 4b; the first support plate 3a is sleeved on the other end of the FRP fiber reinforcement 1, and the FRP fiber reinforcement 1 is supported by the first anchor 4a. The other end of the fiber tendon 1 is fixed on the first support plate 3a.

[0017] Such as figure 1 , consisting of FRP fiber reinforcement 1 with casing, concrete pile body 2, first support plate 3...

Embodiment 2

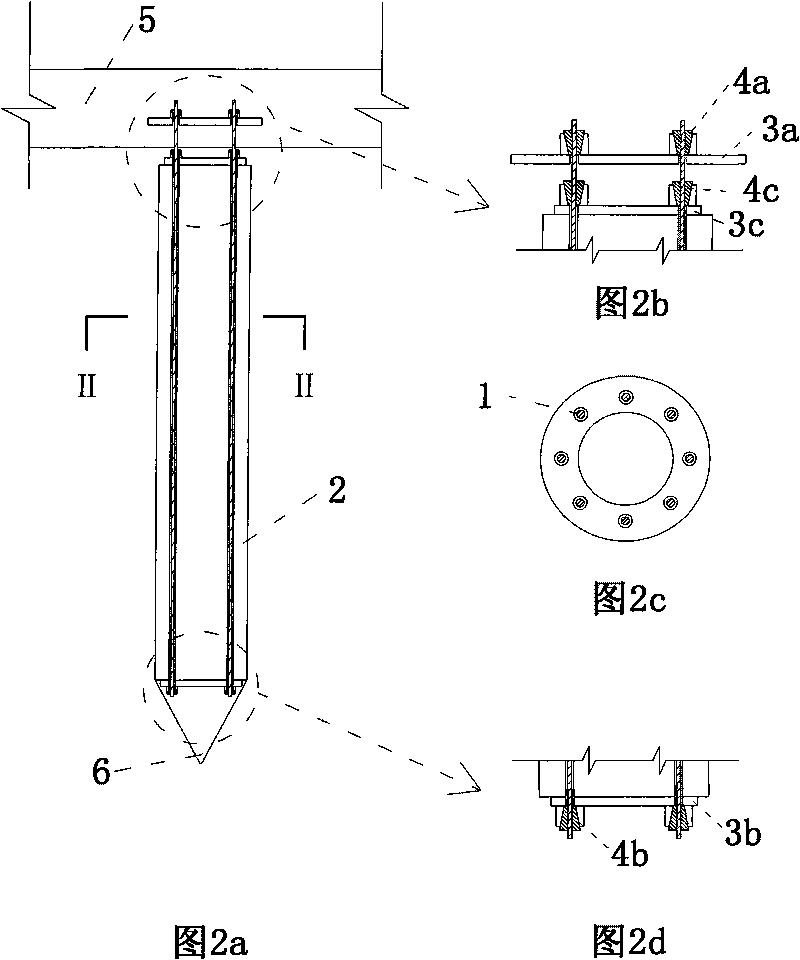

[0019] A fiber-reinforced concrete uplift pile, comprising: a concrete pile body 2, a pile head 6 is arranged on one end of the concrete pile body 2, and an FRP fiber reinforcement 1 with an external sleeve sleeve is arranged inside the concrete pile body 2 And one end of the FRP fiber reinforcement 1 extends into the pile head 6, and the other end of the FRP fiber reinforcement 1 extends out of the concrete pile body 2 in reverse; a second support plate 3b is provided in the pile head 6, located at One end of the FRP fiber reinforcement 1 in the pile head 6 is fixed on the second support plate 3b by the second anchor 4b; the first support plate 3a is sleeved on the other end of the FRP fiber reinforcement 1, and the FRP fiber reinforcement 1 is supported by the first anchor 4a. The other end of the fiber reinforcement 1 is fixed on the first support plate 3a. In this embodiment, the other end of the FRP fiber reinforcement 1 is also sleeved with a third support plate 3c, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com