Fcc counter-current regenerator with regenerator riser

A regenerator and riser technology, applied in the field of countercurrent catalyst regenerators, can solve the problems of large size and high construction cost of FCC regenerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

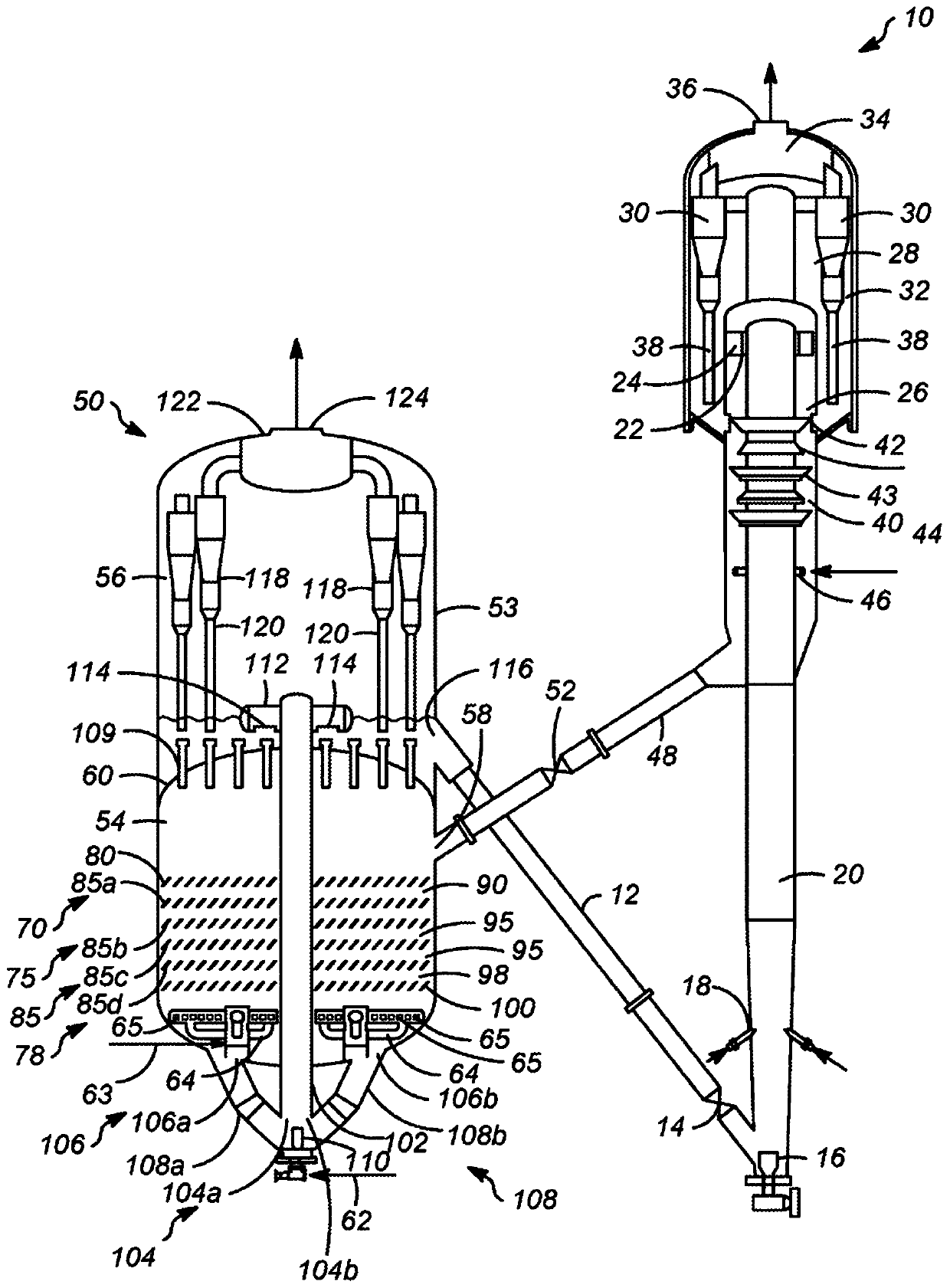

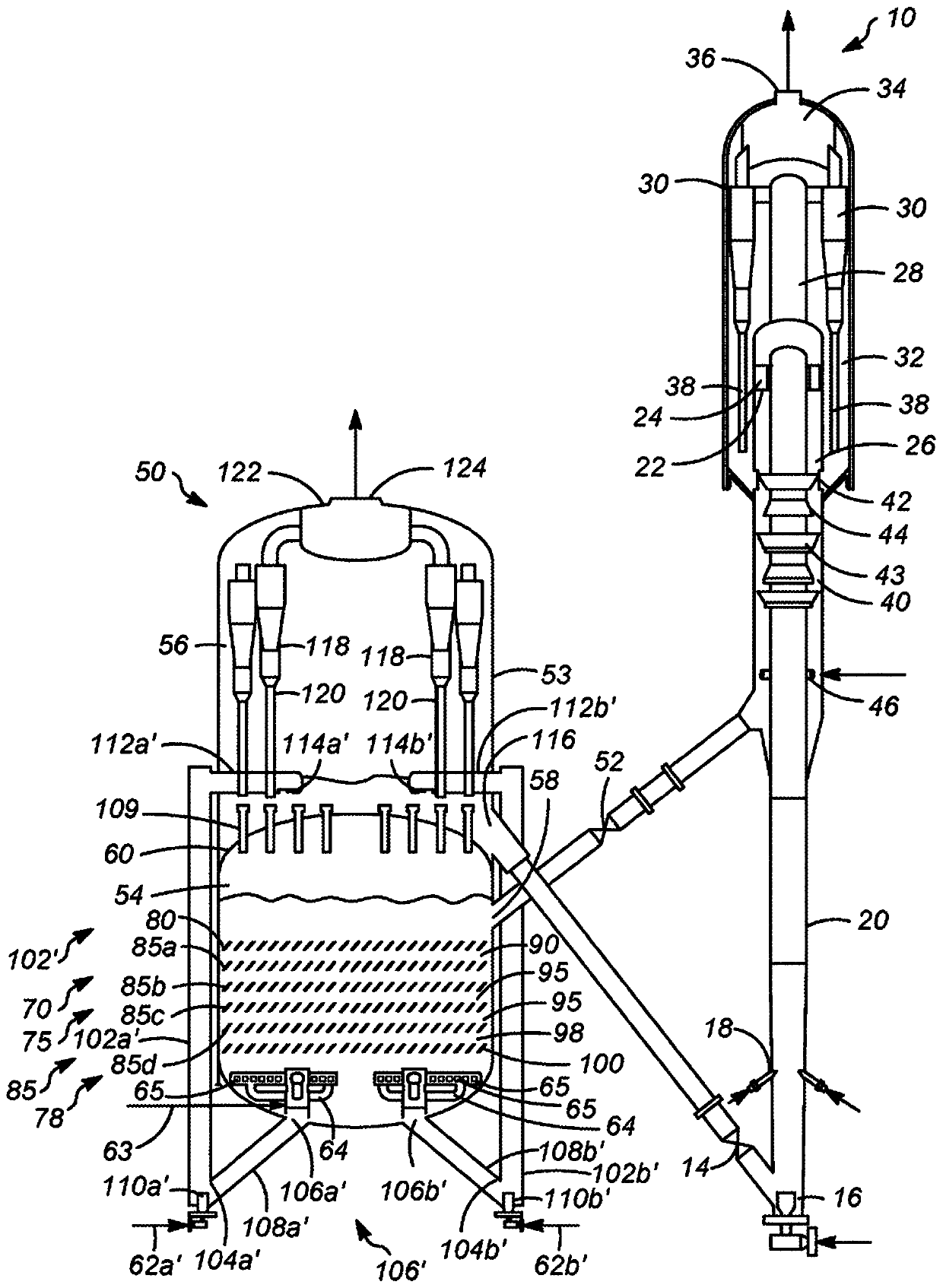

[0016] A new regenerator is proposed where the catalyst and gas streams are countercurrent to each other in multiple stages and are provided with either an internal regenerator riser or an external regenerator riser to facilitate catalyst delivery. A permeable barrier above each stage facilitates countercurrent flow of catalyst by alleviating catalyst back mixing. The permeable barrier may also have a structure that promotes efficient mixing between the catalyst and combustion gases. Each stage may also include open volume sections between adjacent permeable barriers. From one stage the catalyst flows down through the lower permeable barrier and from the stage the oxygen-containing gas flows up through the upper permeable barrier. One or more stages can be assembled in a regenerator vessel to approximate true countercurrent flow conditions. In addition, the regenerator riser can be used as the final polishing stage for catalyst regeneration after countercurrent regeneration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com