Fcc counter-current regenerator

A regenerator and countercurrent contact technology, which is applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as hot spots, increased catalyst deactivation, and reduced combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

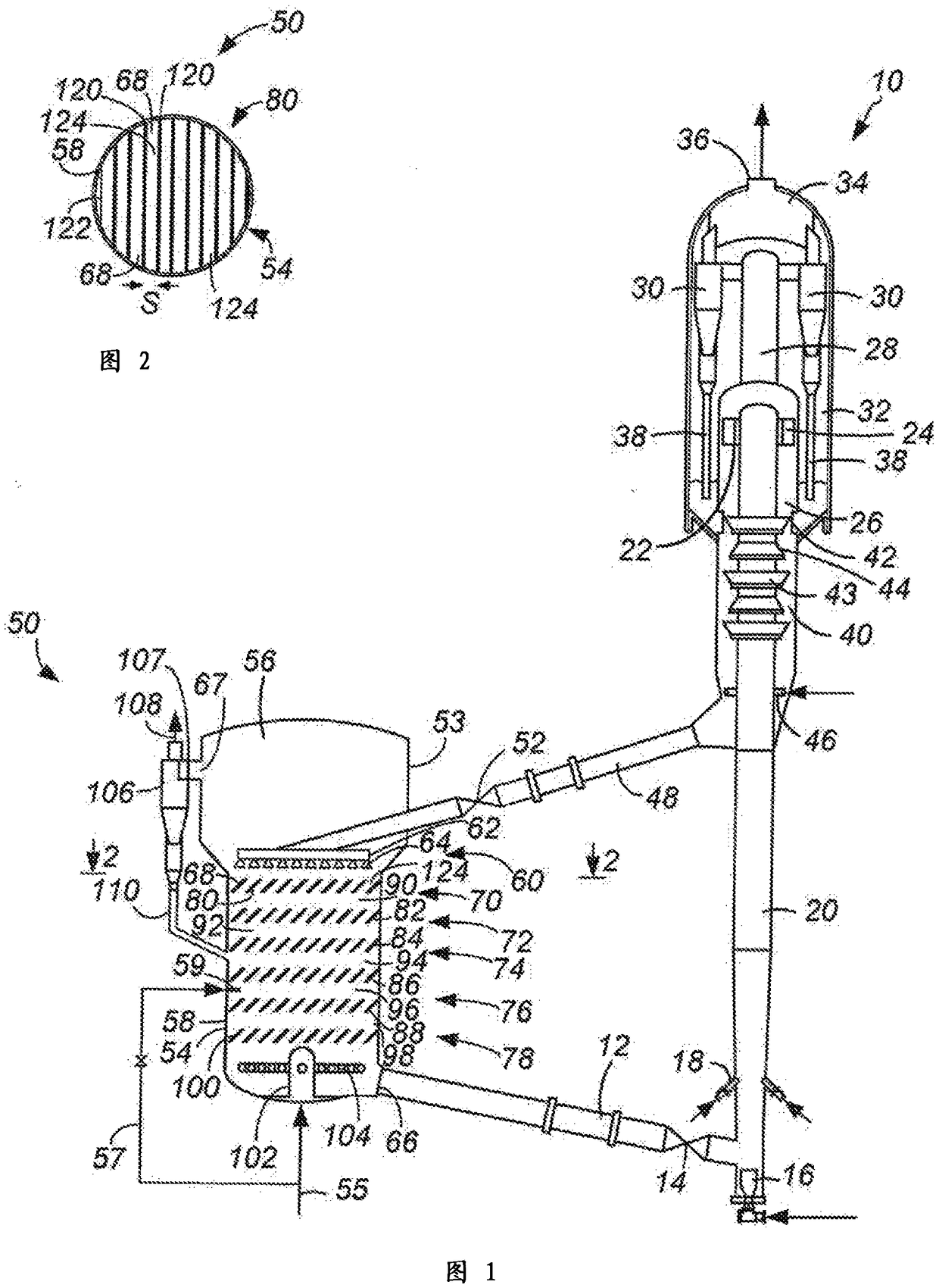

Method used

Image

Examples

Embodiment 1

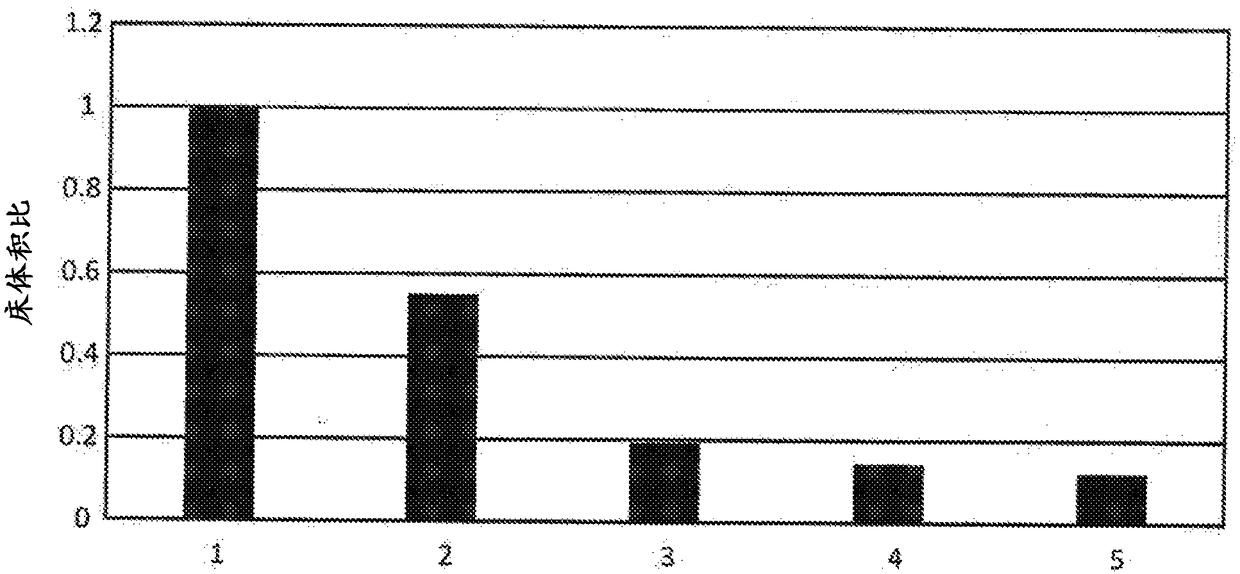

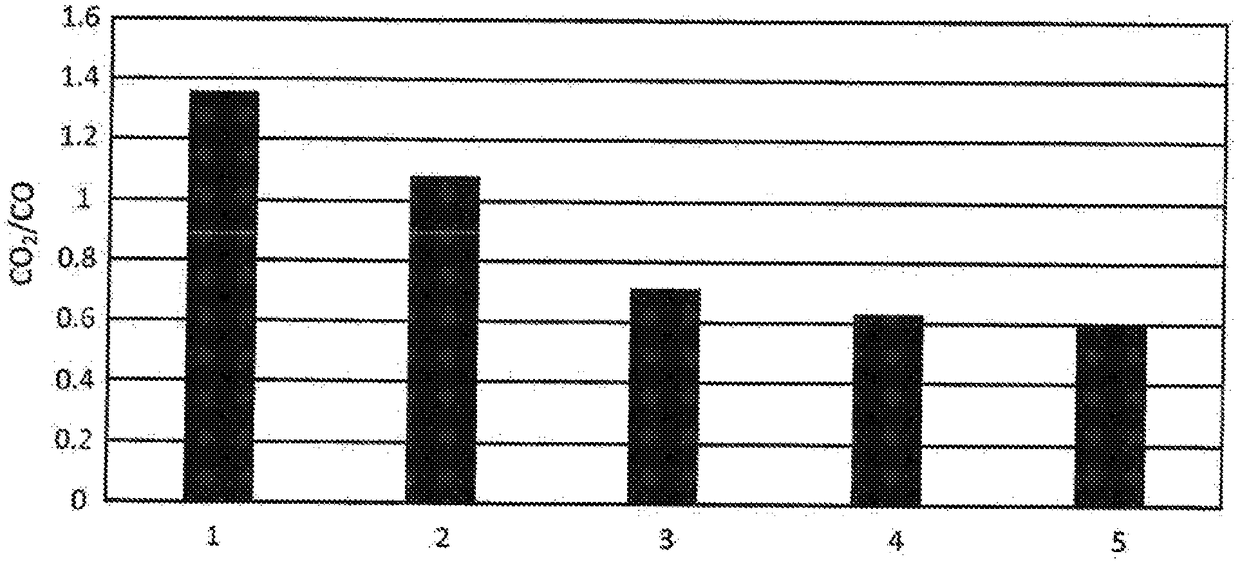

[0070] We performed kinetic simulations comparing bubbling bed regenerators and two to five stage countercurrent regeneration. The bubbling bed is modeled more rigorously than the single-stage continuous stirred tank reactor model in a manner that can be used for computational fluid dynamics simulations. Each stage of the countercurrent regenerator was modeled as a continuous stirred tank reactor without catalyst dilute phase. All simulation cases used the same total catalyst weight, the same total air weight flow rate, the same coke weight concentration on the coked catalyst and the same target coke concentration on the regenerated catalyst. Therefore, each regenerator simulated must burn the same total mass of coke. For each countercurrent regenerator, the same total mass of coke must be burned throughout the regenerator, but the amount of coke burned in each stage of the countercurrent regenerator is determined by the kinetics that occur in equal volumes at each stage.

...

Embodiment 2

[0074] We simulated a countercurrent regenerator with five-stage countercurrent contacting under the same conditions as in Example 1.

[0075] Figure 5 is a graph of the weight percent coke concentration on the catalyst on the left axis and the volume percent oxygen concentration in the gas on the right axis for each countercurrent regeneration stage. The first stage where the coked catalyst was first sent to the regenerator had the highest coke concentration and the lowest coke concentration in the fifth stage, which was the final stage of this study. Oxygen is highest in the final stage of its first distribution and lowest in the first stage. The counter-current arrangement allows the greatest concentration of oxygen to be present at the stage where the coke concentration is lowest and most difficult to burn, and the least oxygen concentration to exist where the coke concentration is highest and most flammable. Therefore, high oxygen concentration or high coke concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com