Rotor assembly

A component and rotor technology, applied in the field of rotor components, can solve problems such as poor bearing performance and difficulty in ensuring, and achieve the effect of increased life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

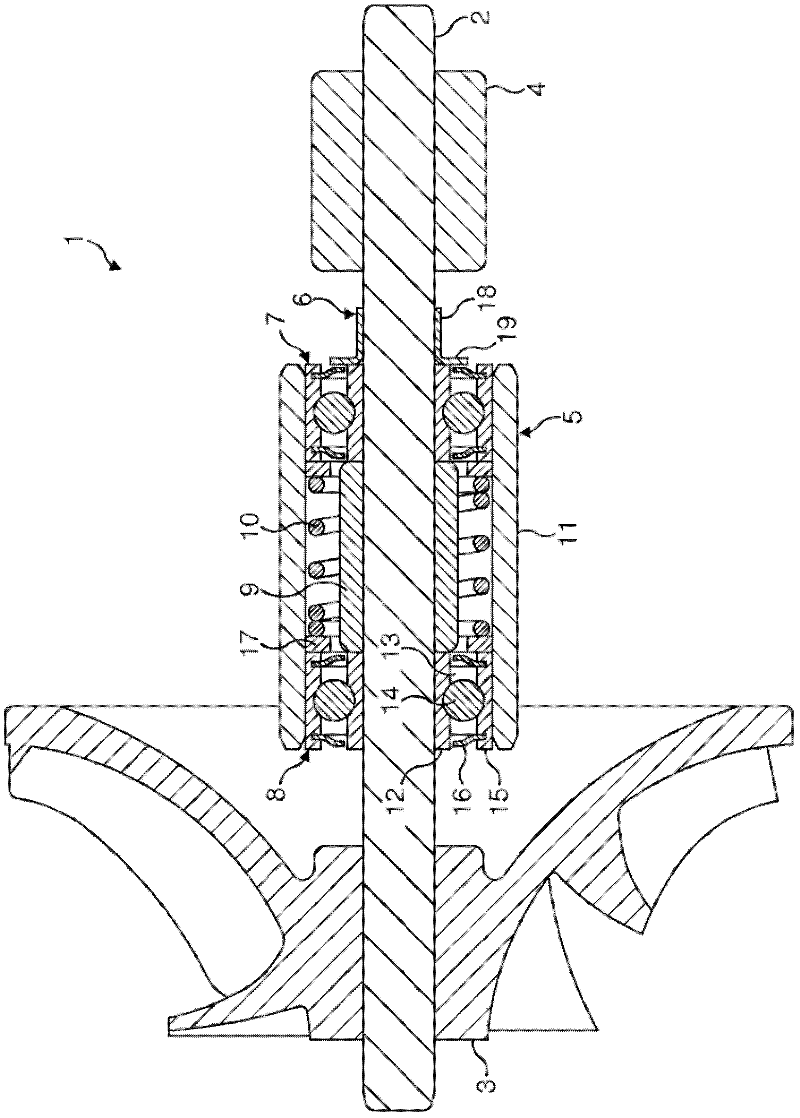

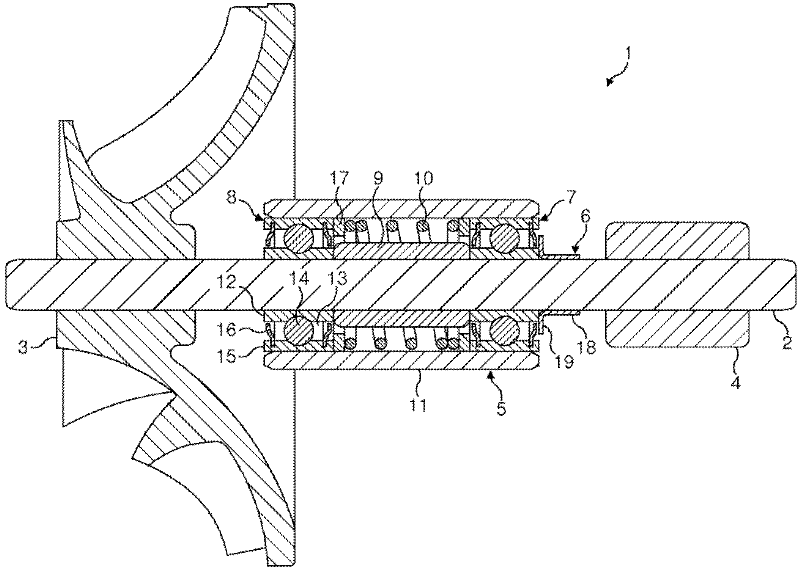

[0017] figure 1 The rotor assembly 1 includes a shaft 2, an impeller 3, a rotor core 4, a bearing cylinder 5 and a dust cover 6 are mounted to the shaft 2.

[0018] The impeller 3 is mounted to the first end of the shaft 2 . exist figure 1 The impeller 3 shown in is a centrifugal impeller. However, other types of impellers may equally be used depending on the intended application of the rotor assembly 1 .

[0019] A rotor core 4 is mounted to the second end of the shaft 2 . The rotor core 4 is formed of hard magnetic or soft magnetic material. The shaft 2 is formed of a soft magnetic material, which then reduces the reluctance of the magnetic circuit. However, a non-magnetic material could be used for the shaft 2 instead.

[0020] The bearing cartridge 5 is located between the impeller 3 and the rotor core 4 . The bearing cartridge 5 includes a pair of bearings 7 , 8 , a spacer 9 , a spring 10 and a sleeve 11 .

[0021] The bearings 7, 8 are identical, each comprising ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com