Silicon rod glue joint machine with single clamping bracket

A technology of clamping mechanism and silicon rod, which is applied in the direction of manufacturing tools, stone processing equipment, working accessories, etc., can solve the problems of difficult normal production, uneconomical, waste of energy, etc., and achieve the reduction of adjustment distance, simple structure, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

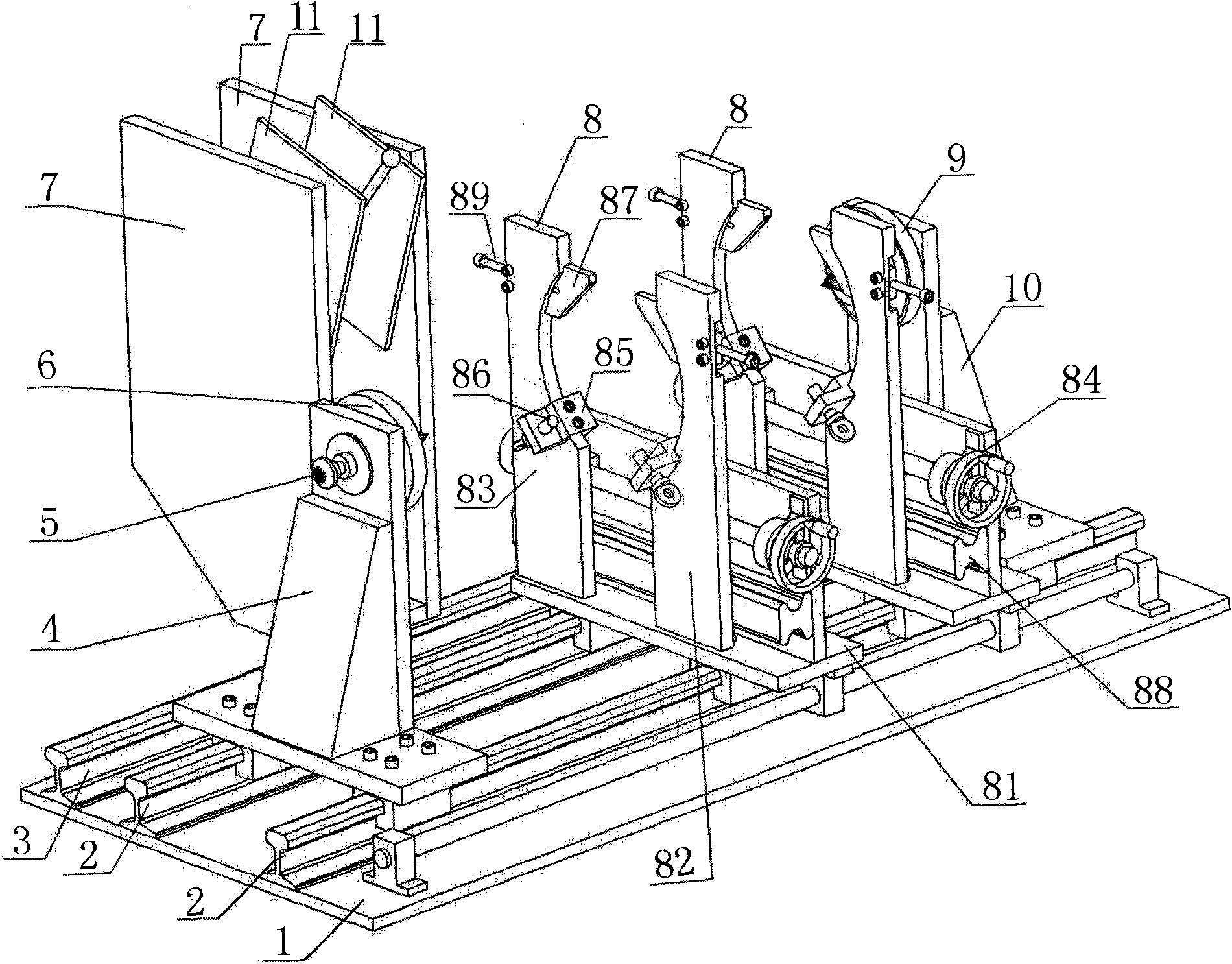

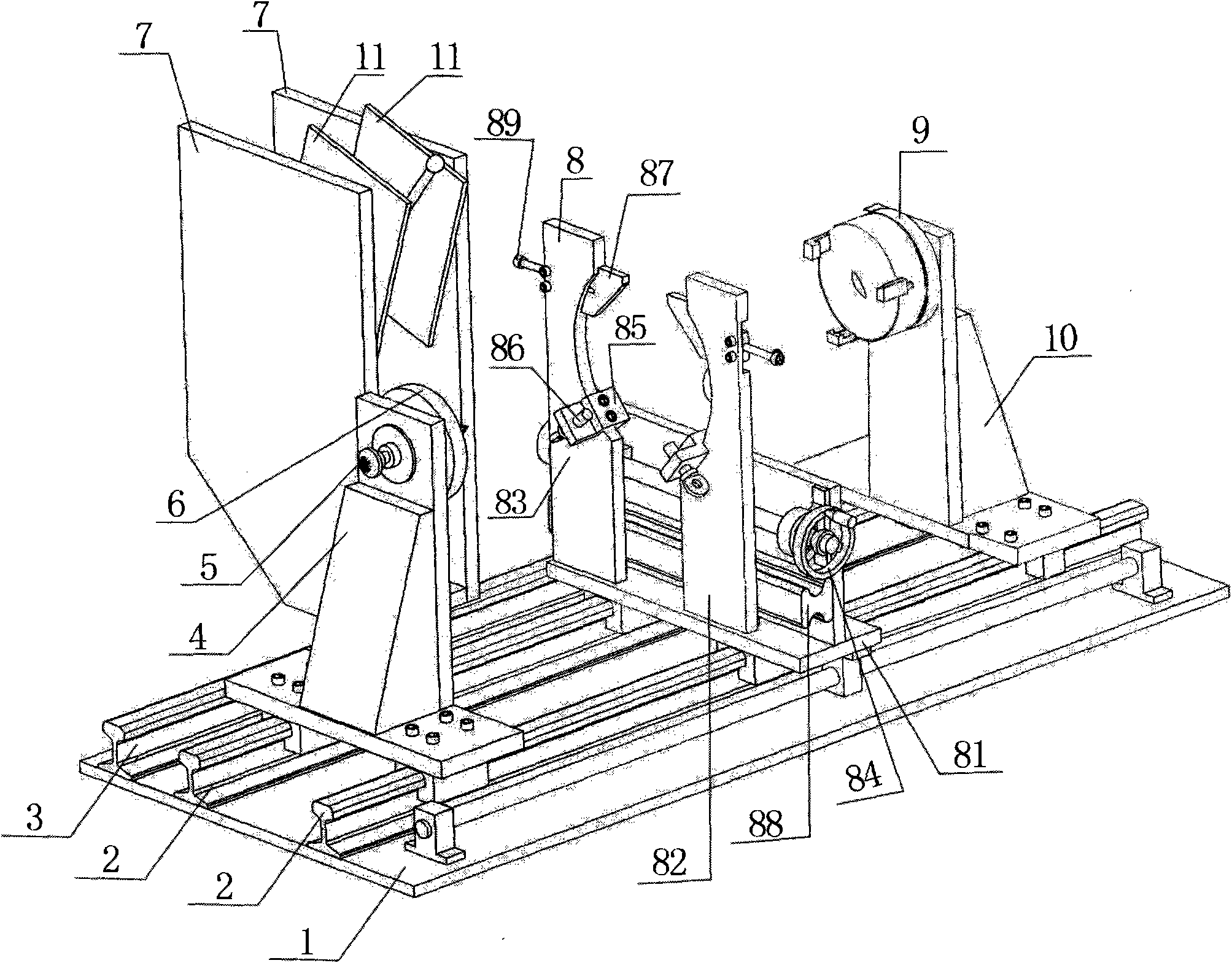

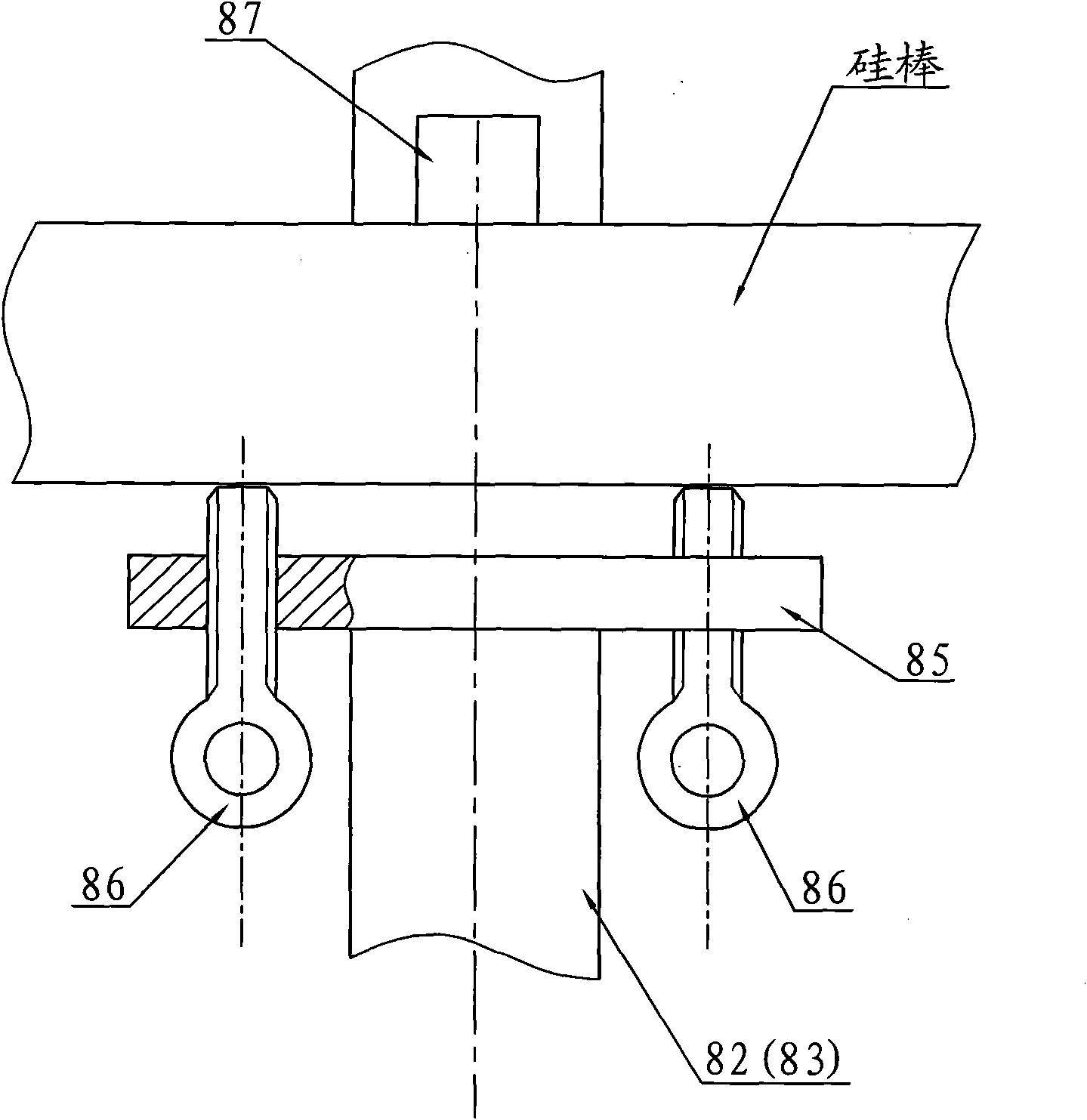

[0014] A single clamping frame silicon rod gluing machine, as attached figure 2 , image 3 As shown, it consists of a base 1, a silicon rod support guide rail 2, a heating device guide rail 3, a left slide seat 4, an adjusting screw 5, a circle center calibration disc 6, a heating device 7, a silicon rod clamping mechanism 8, a three-jaw chuck 9, The right slide 10 is composed of a crystal holder 11, the silicon rod support rail 2 and the heating device guide rail 3 are fixed on the base 1 in parallel, the left slide 4 is installed on the silicon rod support guide 2, and is located on the left side of the base 1, the center of the circle The calibration disc 6 is installed on the left sliding seat 4 through the adjusting screw 5; the right sliding seat 10 is also installed on the silicon rod support guide rail 2, and is located on the right side of the base 1, and the three-jaw chuck 9 is installed on the right sliding seat 10, And the center of the three-jaw chuck 9 is coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com