Aqueous emulsion type epoxy asphalt coating and preparation method thereof

A technology of epoxy asphalt and water-emulsion type, which is applied in the direction of asphalt paint, epoxy resin paint, coating, etc., to achieve the effects of highlighting environmental safety, good compatibility, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

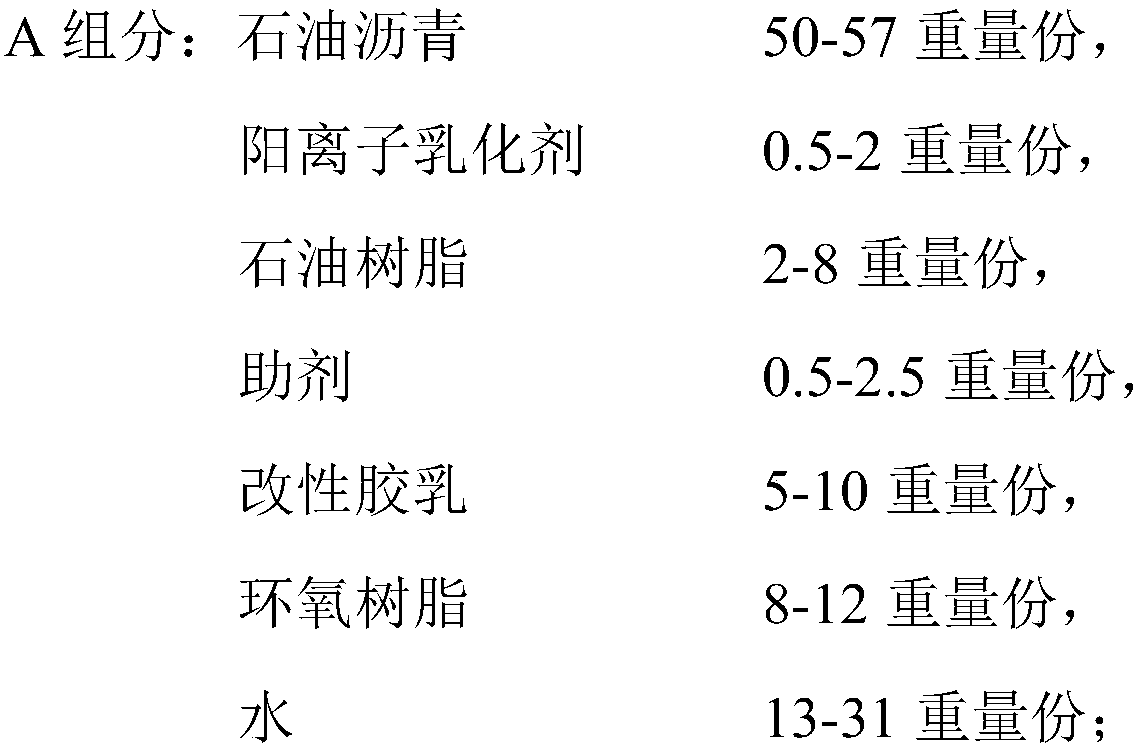

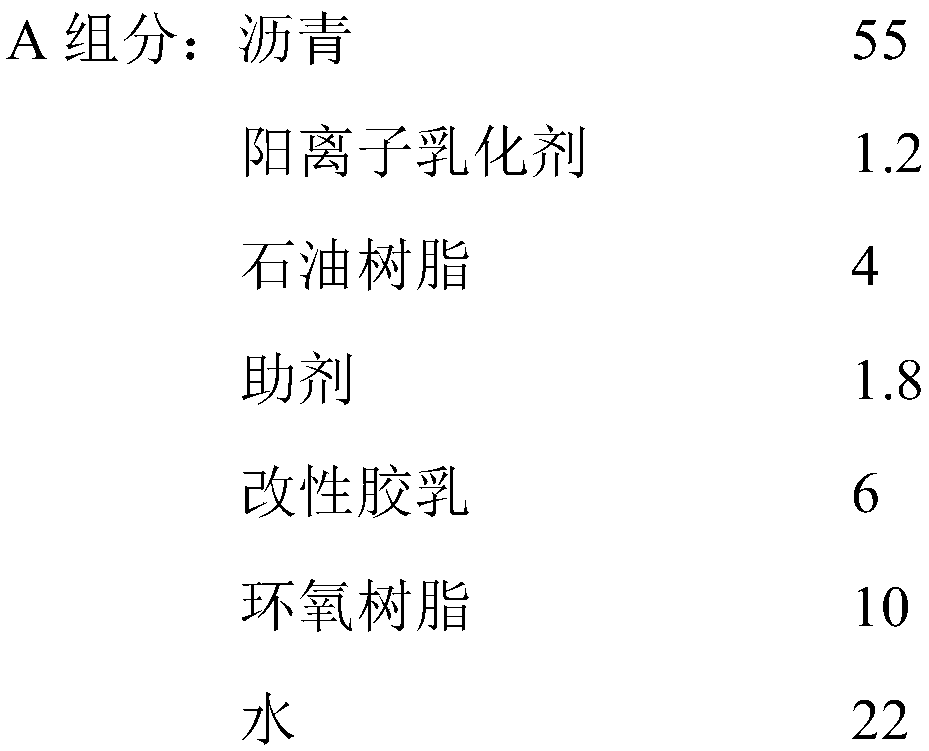

[0038] A kind of water-emulsion type epoxy asphalt paint, comprises the component of following parts by weight:

[0039]

[0040] B component: 593 curing agent 25

[0041] The preparation method is as follows:

[0042] 1) Heating the asphalt to 130°C;

[0043] 2) Add petroleum resin to the heated asphalt in step (1), stir for 1 hour until fully dissolved to form modified asphalt, then cool down to 130°C for later use;

[0044] 3) warming up the water to 55°C;

[0045] 4) Add cationic emulsifier, auxiliary agent, modified latex, and epoxy resin to the heated water in step (3), and stir for 1 hour until a soap liquid with a uniform dissolved state is formed;

[0046] 5) Mix the cooled modified asphalt with the soap solution, carry out shearing and emulsification through a colloid mill according to a ratio of 5:5, cool down to room temperature, and obtain the epoxy emulsified asphalt A component;

[0047] 6) Mix component A and component B according to the mass ratio of 4:...

Embodiment 2

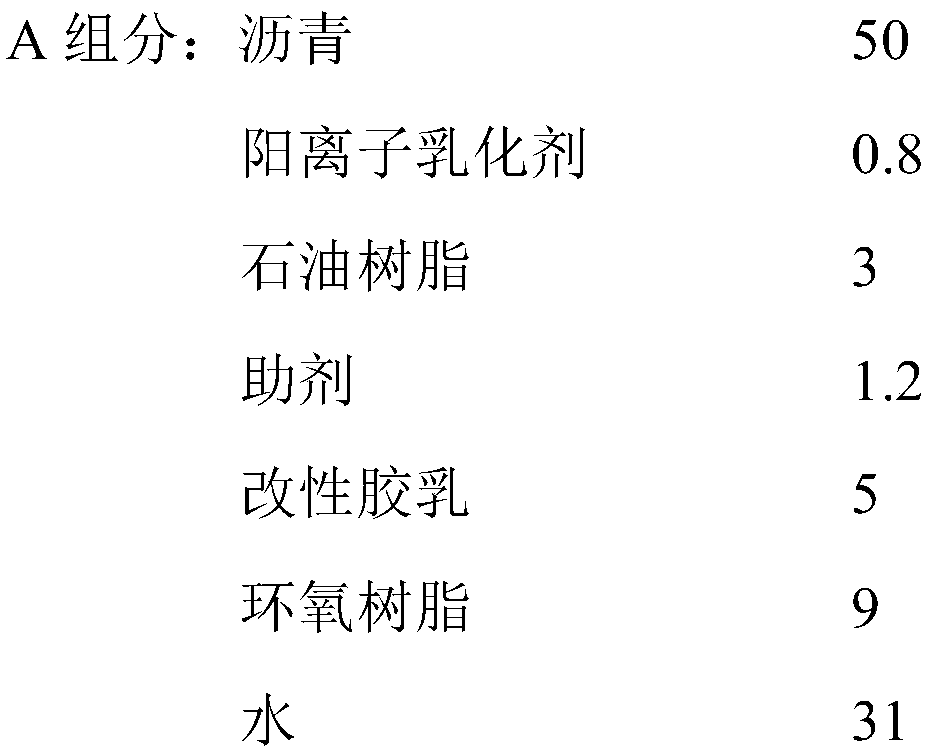

[0049] A kind of water-emulsion type epoxy asphalt paint, comprises the component of following parts by weight:

[0050]

[0051] B component: 593 curing agent 20

[0052] Preparation method is consistent with embodiment 1, only there is following difference:

[0053] In the step (5) of Example 2, the ratio of the modified asphalt to the soap solution is 5:4, and the ratio of the A component to the B component in the step (6) is 5:1.

Embodiment 3

[0055] A kind of water-emulsion type epoxy asphalt paint, comprises the component of following parts by weight:

[0056]

[0057] B component: 593 curing agent 16.7

[0058] Preparation method is consistent with embodiment 1, only there is following difference:

[0059] In the step (5) of Example 2, the ratio of modified asphalt to soap liquid is 5:3, and the ratio of component A to component B in step (6) is 6:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com