Preparation of enviroment protective ceramic water permeable brick

A technology of permeable bricks and ceramics, applied in the field of building materials, can solve the problems of high cost, difficulty in forming, and unfavorable mass production, etc., and achieve the effects of overcoming warping deformation, cost saving, and stable and regular dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

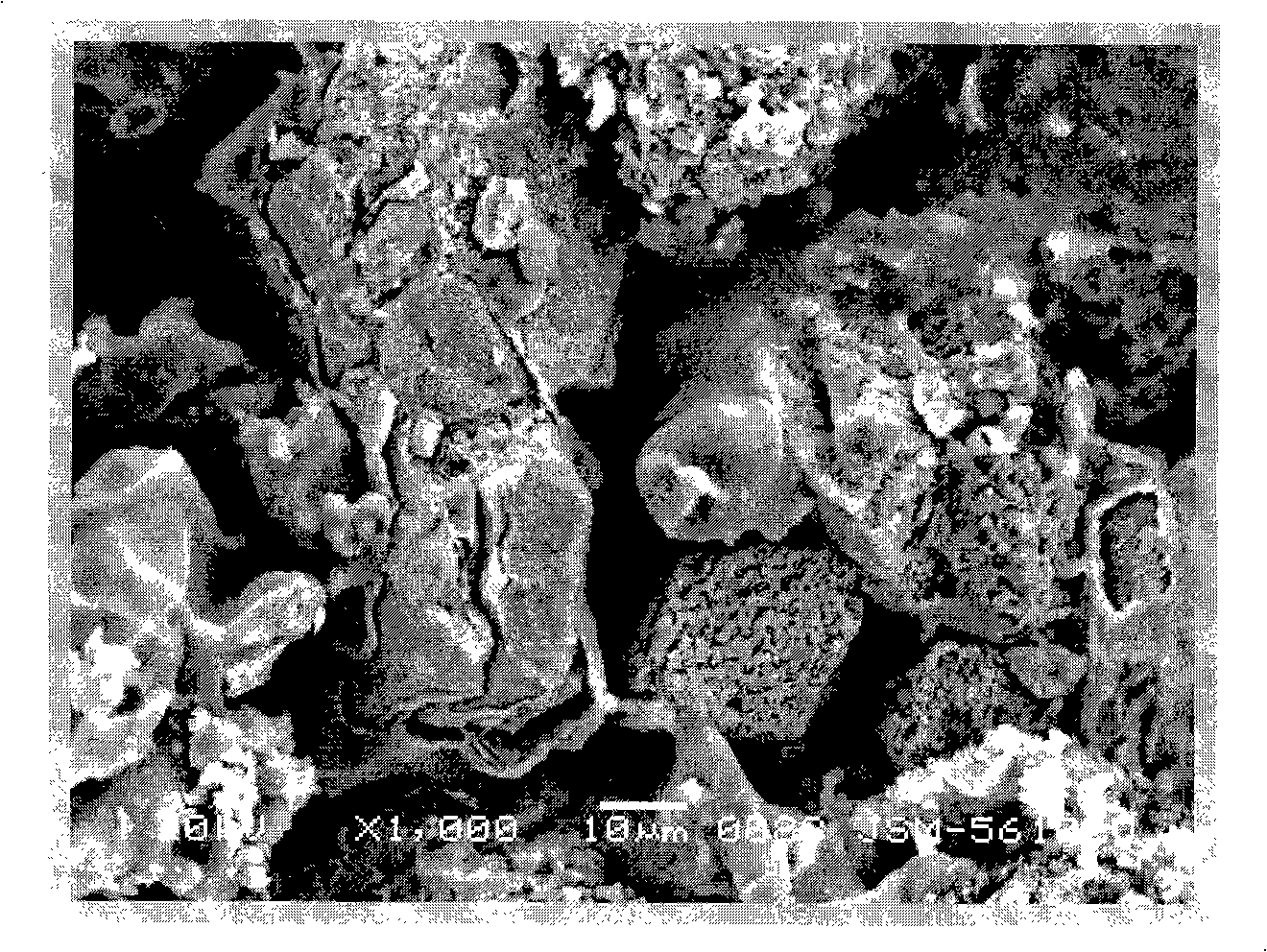

Image

Examples

Embodiment 1

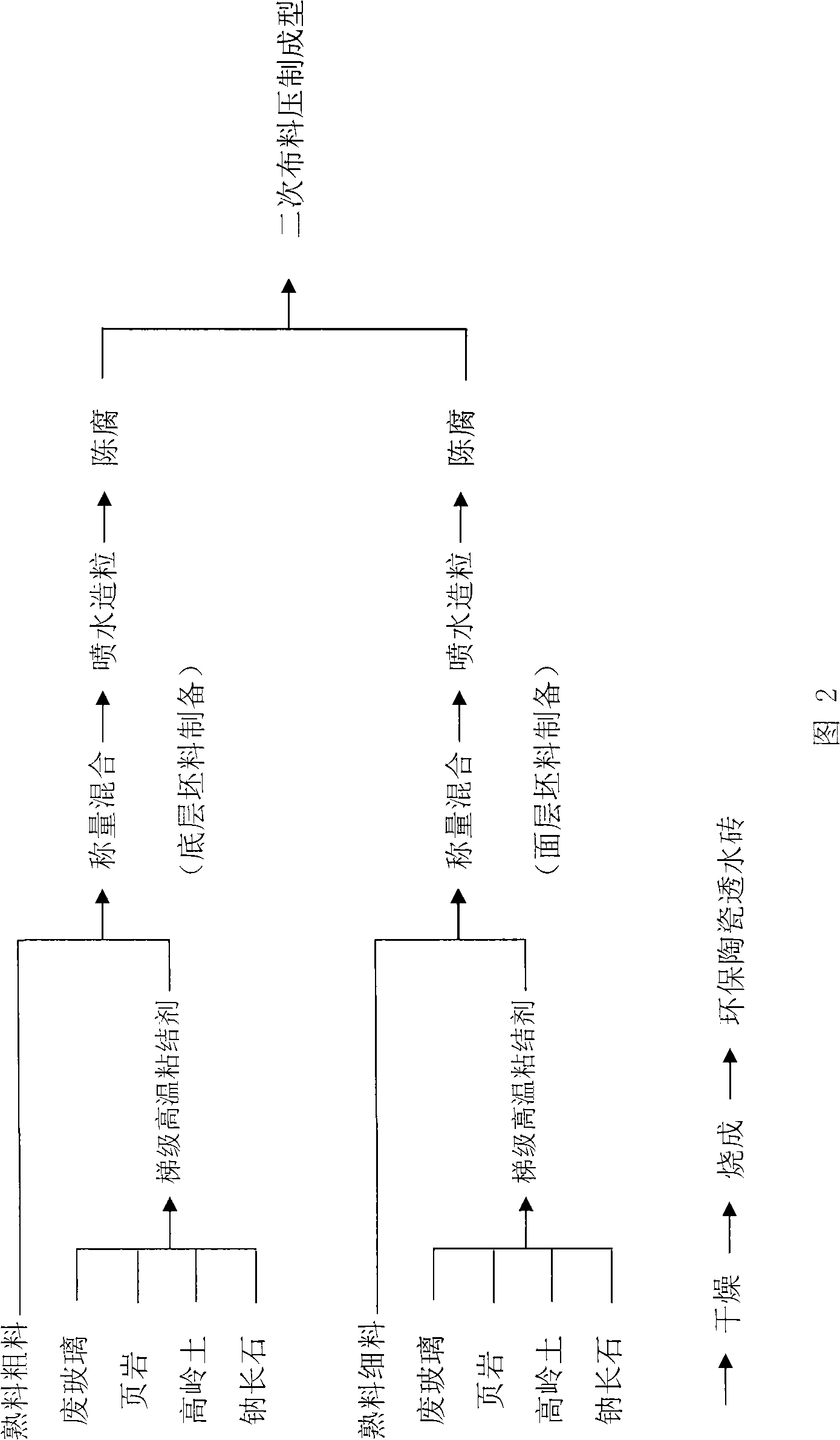

[0031] As shown in Figure 2, the preparation method of environmentally friendly ceramic permeable bricks includes the following steps:

[0032] 1) Preparation of the bottom blank:

[0033] 1. the solid waste clinker is crushed, sieved into coarse particles with a particle diameter of 3mm, and the coarse solid waste clinker (that is, the clinker coarse material in Fig. 2) is obtained for subsequent use; the solid waste clinker is ceramic waste (sanitary ceramics waste);

[0034] ②Crush waste glass, shale, kaolin, and albite to pass through a 100-mesh sieve respectively; use it as a raw material for cascade high-temperature binder; any of the waste glass, shale, kaolin, and albite raw materials If the seed is wet, dry it at 60-80°C for 24-48 hours; the shale is black shale;

[0035] 3. Percentage by weight: 70% of coarse-grained solid waste clinker, 30% of cascaded high-temperature binder passing through a 100-mesh sieve. ; Wherein, the cascaded high-temperature binder is a m...

Embodiment 2

[0048] The preparation method of environment-friendly ceramic permeable brick, it comprises the following steps:

[0049] 1) Preparation of the bottom blank:

[0050] 1. The solid waste clinker is crushed, sieved into coarse grains with a particle size of 3mm, and the coarse solid waste clinker is obtained for subsequent use; the solid waste clinker is the waste refractory brick of the iron and steel plant;

[0051] ② Broken waste glass, shale, kaolin, and albite to pass through a 100-mesh sieve, and use them as raw materials for cascade high-temperature binders; any of the waste glass, shale, kaolin, and albite raw materials If the seed is wet, dry at 60-80°C for 24-48 hours; the shale is siliceous shale;

[0052] 3. Percent by weight: 80% of coarse-grained solid waste clinker, 20% of cascaded high-temperature binder passing through a 100-mesh sieve. ; Wherein, the cascaded high-temperature binder is a mixture of waste glass, shale, kaolin and albite, and the mass ratio of ...

Embodiment 3

[0064] The preparation method of environment-friendly ceramic permeable brick, it comprises the following steps:

[0065] 1) Preparation of the bottom blank:

[0066] ① breaking the solid waste clinker and sieving it into coarse grains with a particle size of 2 mm to obtain coarse solid waste clinker; the solid waste clinker is the waste refractory brick of the cement plant; standby;

[0067] ② Broken waste glass, shale, kaolin, and albite to pass through a 100-mesh sieve, and use them as raw materials for cascade high-temperature binders; any of the waste glass, shale, kaolin, and albite raw materials If the seed is wet, dry it at 60-80°C for 24-48 hours; the shale is black shale;

[0068] 3. Percentage by weight: 60% of coarse-grained solid waste clinker, 40% of cascaded high-temperature binder passing through a 100-mesh sieve. ; Wherein, the cascaded high-temperature binder is a mixture of waste glass, shale, kaolin and albite, and the mass ratio of waste glass, shale, ka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com