Silane modified polyurethane sealing glue with quick surface dry as well as preparation and application thereof

A polyurethane sealant and silane modification technology, which is applied in engine seals, polyurea/polyurethane adhesives, sealing devices, etc., can solve the problems of long dry time of sealants, difficult quality control, and reduced construction efficiency. Achieve the effect of meeting the requirements of assembly process, fast surface drying speed and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

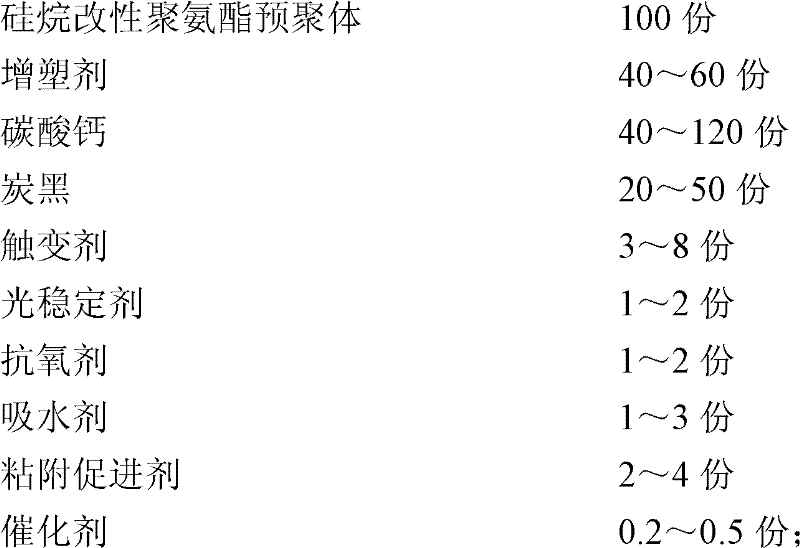

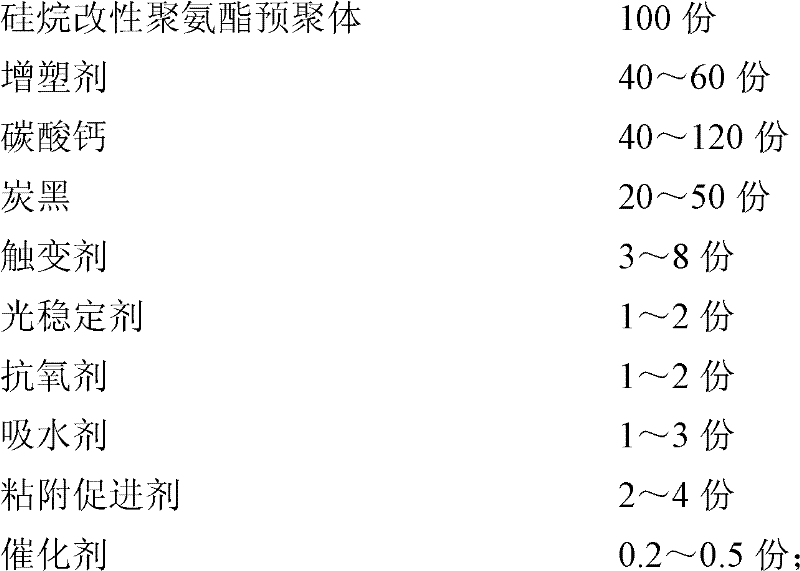

Method used

Image

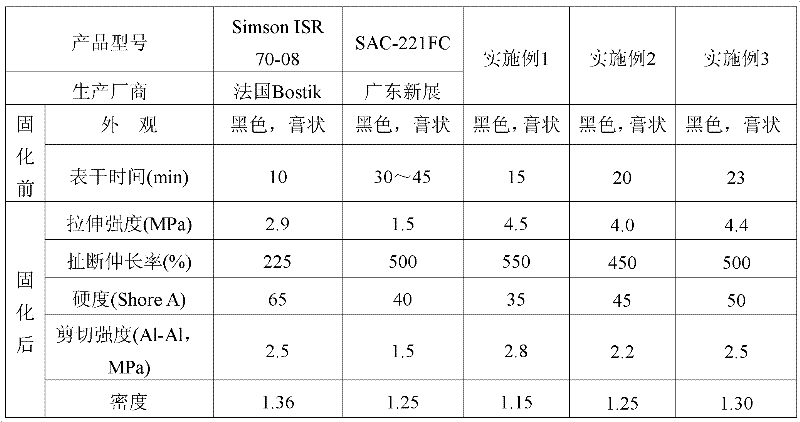

Examples

Embodiment 1

[0044] (1) First place calcium carbonate and carbon black in a constant temperature oven and dry at 120°C for 20 hours;

[0045] (2) 100 parts by weight of SPUR 1015LM, 20 parts by weight of light calcium carbonate, 20 parts by weight of heavy calcium carbonate, 50 parts by weight of carbon black, 40 parts by weight of dioctyl phthalate, 3 parts by weight of gas phase dioxide Silicon (the HB-215 product of Guangzhou Jibisheng Technology Industrial Co., Ltd., the same below), 1 part by weight of 2-(2-hydroxyl-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole, 1 Parts by weight of 2,6-tertiary butyl-4-methylphenol and 1 part by weight of vinyltrimethoxysilane are added to the reaction kettle of the planetary mixer, and the temperature is 80°C, and the vacuum degree is 0.090±0.005MPa. Rotate at 50rpm, maintain 80°C, 0.090±0.005MPa vacuum, stir for 180 minutes, mix well;

[0046] (3) Afterwards, the temperature in the kettle was lowered to 40±5°C, filled with nitrogen, added 2 parts...

Embodiment 2

[0050] (1) Dry calcium carbonate and carbon black in a constant temperature oven at 150°C for 5 hours;

[0051] (2) 100 parts by weight of SPUR 1050MM, 60 parts by weight of light calcium carbonate, 60 parts by weight of heavy calcium carbonate, 20 parts by weight of carbon black, 60 parts by weight of dibutyl phthalate, 8 parts by weight of gas phase dioxide Silicon, 2 parts by weight of 2-(2-hydroxy-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole, 2 parts by weight of bis(3,5-tertiary butyl-4-hydroxyphenyl ) thioether and 2 parts by weight of vinyltriethoxysilane are added to the reaction kettle of the planetary mixer, at a temperature of 90°C and a vacuum of 0.090±0.005MPa at a revolution speed of 50rpm to maintain a temperature of 90°C and a vacuum of 0.090±0.005MPa Vacuum, stir for 120 minutes, mix well;

[0052] (3) After that, the temperature in the kettle was lowered to 40±5°C, filled with nitrogen, added 3 parts by weight of γ-aminopropyltriethoxysilane, and stirred a...

Embodiment 3

[0056] (1) Dry calcium carbonate and carbon black in a constant temperature oven at 140°C for 12 hours;

[0057] (2) 100 parts by weight of SPUR 1050MM, 40 parts by weight of light calcium carbonate, 40 parts by weight of heavy calcium carbonate, 50 parts by weight of carbon black, 50 parts by weight of didecyl phthalate, 4 parts by weight of gas phase dioxide Silicon, 1 part by weight of 2-(2-hydroxy-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole, 1 part by weight of 2,6-tertiary butyl-4-methylphenol and 3 Add vinyltriethoxysilane in parts by weight to a planetary mixer reactor, and stir for 150 minutes at a temperature of 85°C and a vacuum of 0.090±0.005MPa at a revolution speed of 50rpm, maintaining a temperature of 85°C and a vacuum of 0.090±0.005MPa ,well mixed;

[0058] (3) After that, the temperature in the kettle was lowered to 40±5°C, filled with nitrogen, added 4 parts by weight of 3-(2,3-glycidoxy)propyltrimethoxysilane, and stirred at a revolution speed of 50 rpm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com