Polymer composite membrane, preparation method thereof, polymer composite membrane prepared by method, gel electrolyte and lithium ion battery

A polymer and composite film technology, applied in the field of lithium-ion batteries, can solve the problems of poor adhesion of fiber layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

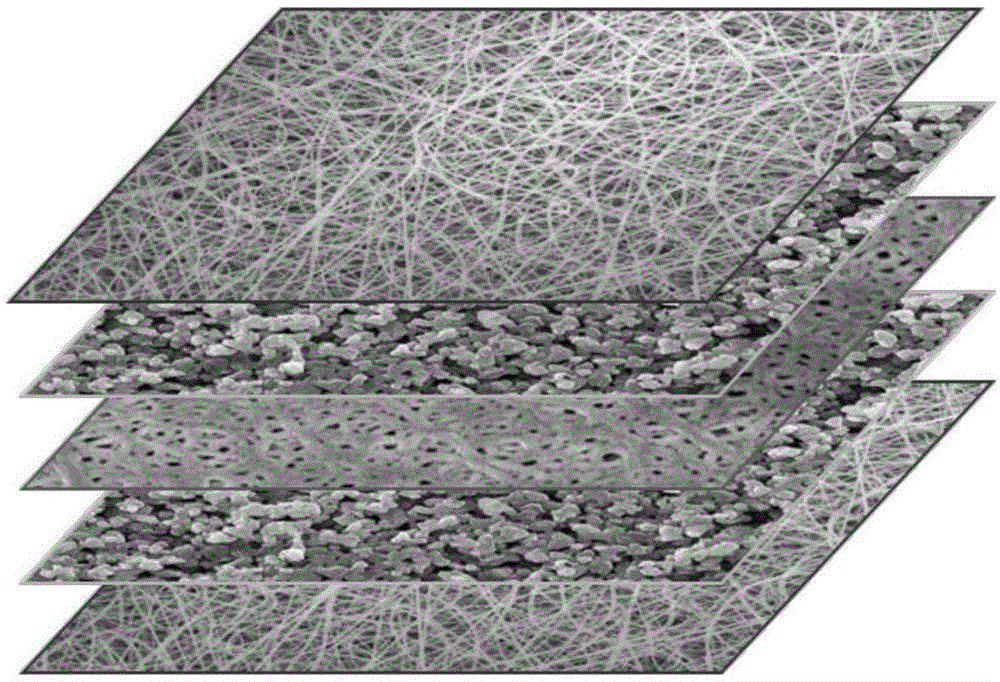

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method for the above-mentioned polymer composite film, comprising the steps of:

[0046] S1, provide diaphragm;

[0047] S2. Provide a spinning solution, the spinning solution includes a mixed solvent and a spinning polymer dissolved in the mixed solvent; the mixed solvent includes a low boiling point solvent with a boiling point of 150-170°C and a boiling point of 175- A high boiling point solvent at 220°C, the mass ratio of the low boiling point solvent to the high boiling point solvent is 7:3-3:7;

[0048] S3. Using the spinning solution to perform electrospinning on the separator, and obtain a polymer composite membrane with a fiber layer on the separator after drying.

[0049] According to the present invention, as in step S1 above, a diaphragm is firstly provided, and subsequent operations are performed on the surface of the diaphragm using the diaphragm as a substrate. As mentioned above, the separator can be a ...

Embodiment 1

[0085] This example is used to illustrate the polymer composite membrane disclosed in the present invention and its preparation method, gel electrolyte and lithium ion battery.

[0086] 1. Preparation of multilayer film

[0087] SiO with an average particle size of 1 μm 2 Granules, binder (PVDF) and coating solvent (NMP) are mixed into a slurry at a weight ratio of 19:1:200, and SiO is coated on both sides of a 11 μm thick PE diaphragm by coating method 2 Particle layer, after drying, a three-layer film A1 with a thickness of 15 μm is formed, in which the thickness of the PE separator is 11 μm, and both sides of the PE separator are SiO with a thickness of 2 μm 2 Inorganic particle layer.

[0088] 2. Preparation of spinning solution

[0089] Mix NMP and DMF uniformly at a mass ratio of 7:3 to form a mixed solvent, then add PVDF, stir magnetically in a water bath at 50°C to fully dissolve, and form a spinning solution with a concentration of 15wt% P(VDF-HFP) B1.

[0090] 3...

Embodiment 2

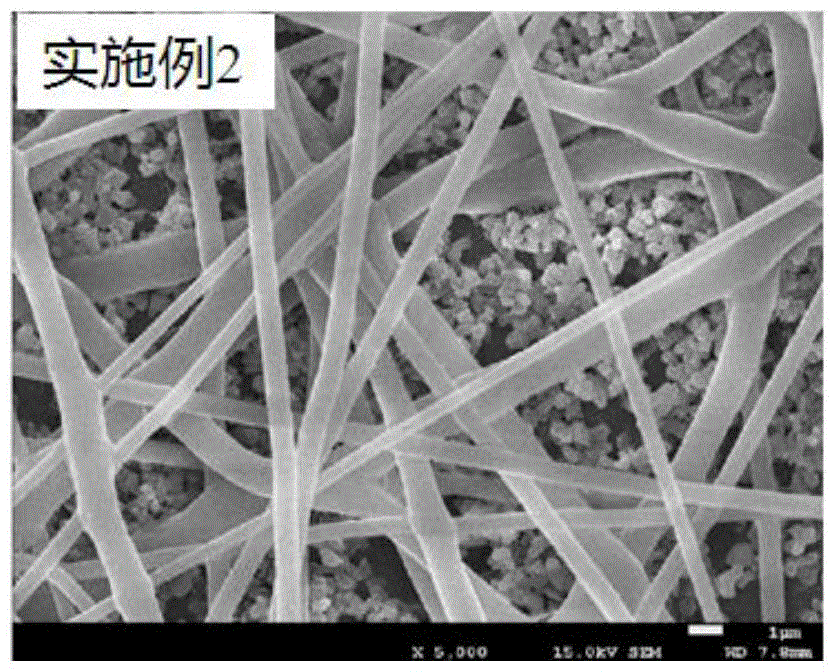

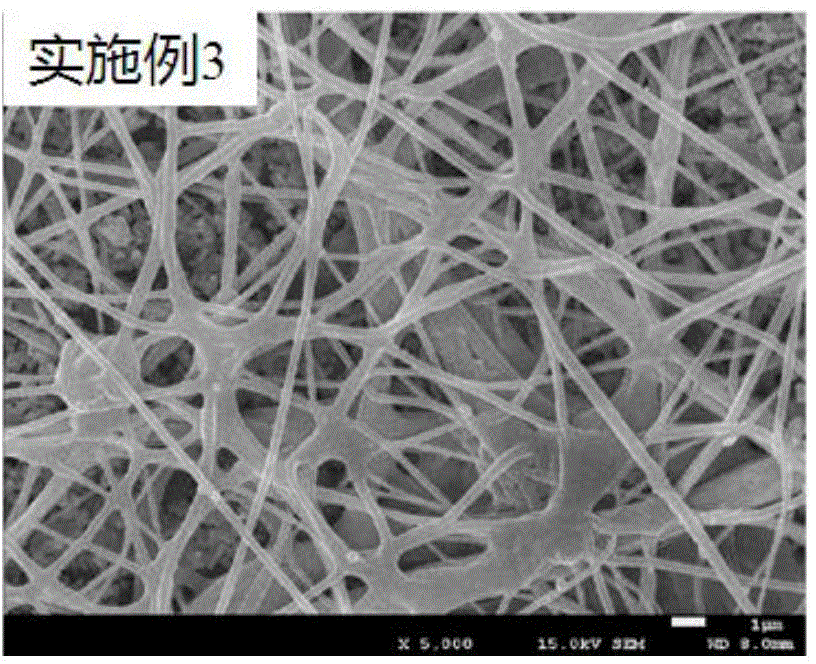

[0096] This example is used to illustrate the polymer composite membrane disclosed in the present invention and its preparation method, gel electrolyte and lithium ion battery.

[0097] 1. Preparation of multilayer film

[0098] Al with an average particle size of 615nm 2 o 3 Granules, binder (PEO) and coating solvent (deionized water) were mixed into a slurry at a weight ratio of 9:1:67, and Al was coated on both sides of a 11 μm thick PE diaphragm by coating method 2 o 3 Particle layer, after drying, a three-layer film A2 with a thickness of 15 μm is formed, in which the thickness of the PE separator is 11 μm, and both sides of the PE separator are Al with a thickness of 2 μm 2 o 3 Inorganic particle layer.

[0099] 2. Preparation of spinning solution

[0100] Mix NMP and DMF uniformly at a mass ratio of 5:5 to form a mixed solvent, then add P(VDF-HFP), wherein the content of HFP copolymerization units is 5wt%, and magnetically stir in a water bath at 50°C to fully dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com