Preparation method of lithium ion battery pole piece containing PTC coating

A lithium-ion battery and pole piece technology, applied in electrode manufacturing, battery electrodes, batteries, etc., can solve the problems of battery fire or explosion, high electrochemical reaction activity, etc., achieve reduced transfer speed, good conductivity, and prevent reaction from heating up Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

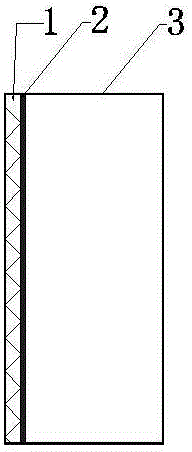

[0022] The preparation method of the lithium-ion battery pole sheet containing PTC coating provided by the present invention, the lithium-ion battery is provided with positive and negative electrode sheets formed by coating a slurry containing positive and negative active materials on the current collector 1, Contains the following steps.

[0023] Step 1, add the binder, positive temperature type material, and conductive agent in the solvent according to the weight percentage of 20%~80%, 10%~80%, 0%~70%, and mix evenly to make a precoat 2 coating ; Precoat 2 coating, wherein the solid content is 5-20% by weight; the solvent is preferably an organic solvent, more preferably N-methylpyrrolidone (NMP); and preferably, the binder and the solvent Mix, then add positive temperature type material and conductive agent respectively and mix evenly to prepare precoat 2 coating with solid content of 10% by weight.

[0024] Step 2, coating the precoat 2 coating obtained in step 1 on the c...

Embodiment 1

[0035] Pre-coating 2 mixture: Weigh the materials according to the ratio of 50% wt%, 45% wt%, and 5% wt% of binder PVDF, polyethylene-based composite conductive polymer material, and conductive carbon black Super P, respectively. First, the binder PVDF was dissolved in the solvent NMP, and then polyethylene-based composite conductive polymer material and conductive carbon black Super P were added respectively, and the pre-coating 2 coating with a solid content of 10% wt% was prepared after mixing evenly.

[0036] The above-mentioned pre-coating 2 paint is coated on the aluminum foil, and dried to form a conductive aluminum foil with temperature characteristics.

[0037]The positive electrode is made of ternary material NCM111, and the negative electrode is made of artificial graphite. The positive and negative electrode slurries are prepared respectively. The prepared positive electrode slurry is coated on the above-mentioned conductive aluminum foil with temperature characteri...

Embodiment 2

[0039] Pre-coat 2 mixture: 50% wt%, 40% wt%, 5% wt%, 5% by binder PFTE, polyethylene-based composite conductive polymer material, conductive carbon black Super P, and conductive graphite Ks-6, respectively The ratio of % wt% is weighed material. Mix the binder PFTE with the solvent NMP, then add polyethylene-based composite conductive polymer material, conductive carbon black Super P, and conductive graphite Ks-6, and mix well to form a pre-coat with a solid content of 10% wt%. 2 paints.

[0040] The above-mentioned pre-coating 2 paint is coated on the aluminum foil, and dried to form a conductive aluminum foil with temperature characteristics.

[0041] The positive electrode is made of lithium iron phosphate material, and the negative electrode is made of artificial graphite. The positive and negative electrode slurries are prepared respectively, and the prepared positive electrode slurry is coated on the above-mentioned conductive aluminum foil with temperature characterist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com