Preparation method for three-dimensional porous graphene for supercapacitor

A supercapacitor, three-dimensional porous technology, applied in the field of energy material graphene preparation, can solve the problems of restricting development, graphene specific surface size and surface structure, etc., to improve specific capacity and conductivity, reduce agglomeration degree, improve The effect of surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

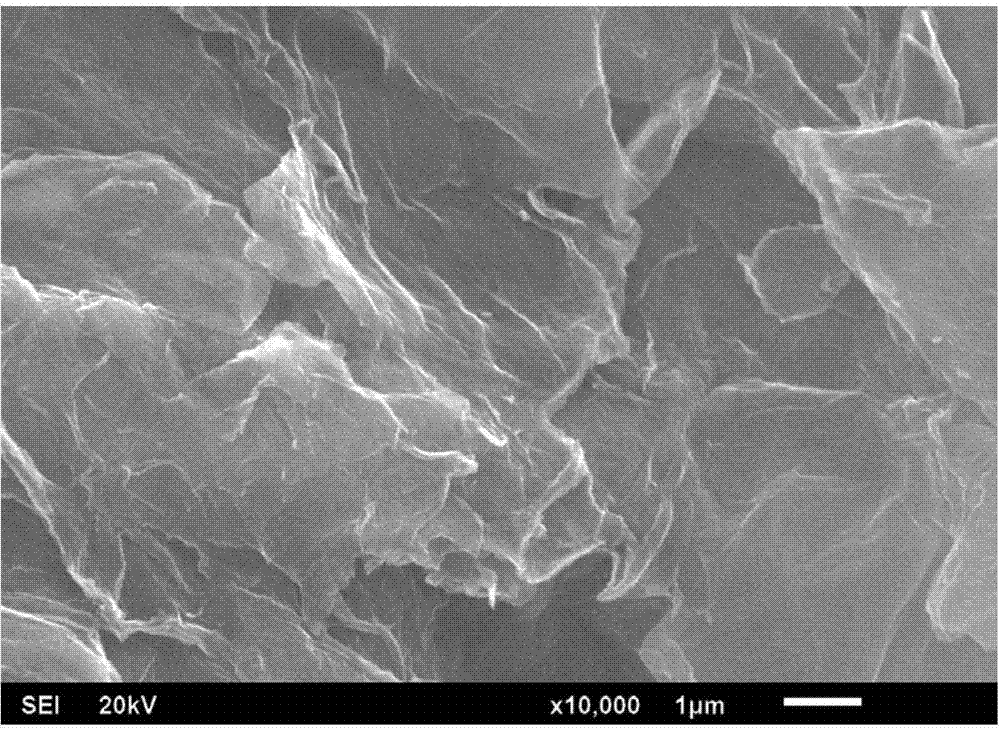

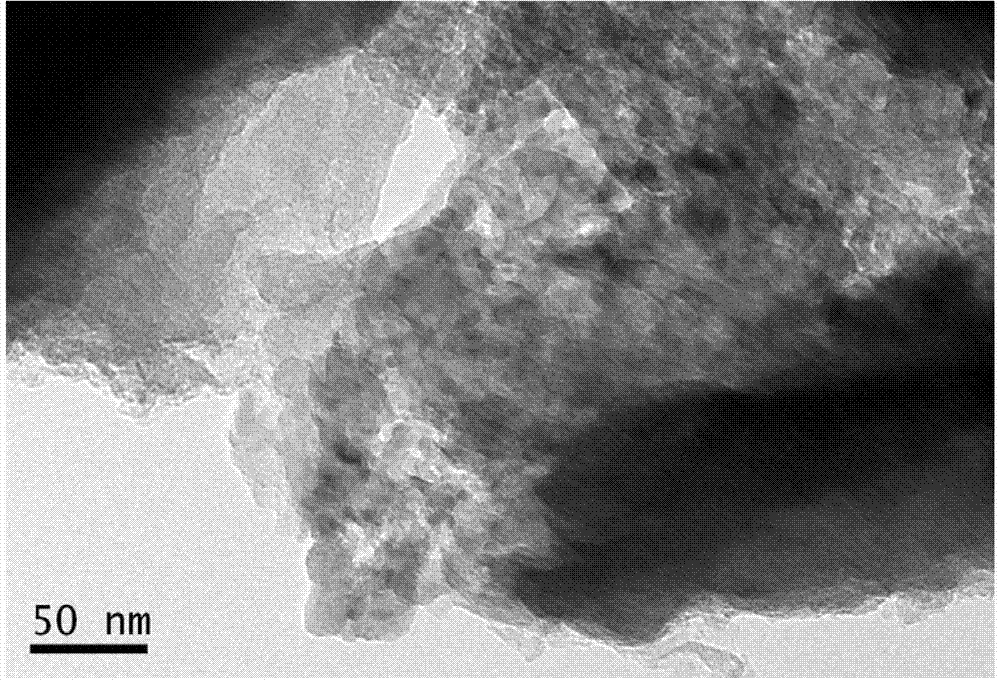

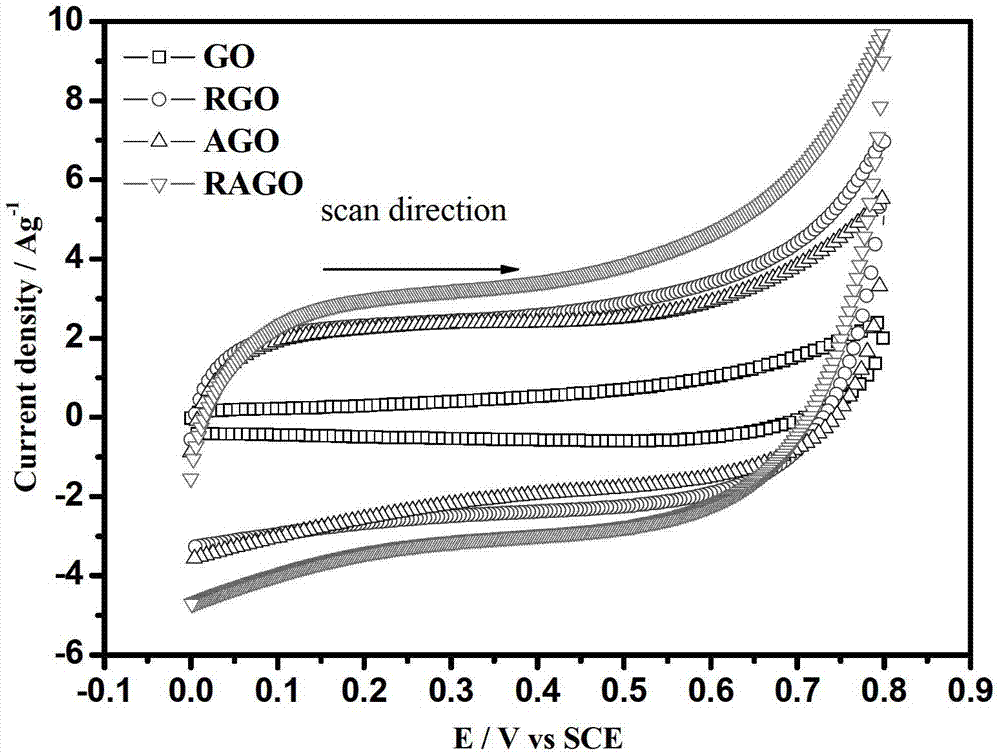

[0027] 50 mg of graphene oxide (GO) was weighed and ultrasonically dispersed in 2 mL of deionized water, and ultrasonically treated for 2 h. At the same time, a 7M KOH solution was prepared, and 5 mL of a strong alkali solution was added to the dispersed graphene oxide slurry, and ultrasonic treatment was continued for 2 h. The mixed solution was transferred to a high-temperature ceramic container, and air-dried at 50°C until the surface of the slurry was wet. Transfer the wet slurry to a vacuum drying oven at 180°C for 1 hour, then fully dissolve the obtained solid product in deionized water, and use the prepared 1M dilute hydrochloric acid solution to neutralize to a pH of about 7. The slurry obtained after neutralization was suction filtered and washed three times, and the obtained solid product was dried under vacuum at 50°C to obtain activated graphene oxide (AGO). SEM image of activated graphene oxide figure 1 As shown, the transmission electron microscope image is sho...

Embodiment 2

[0030] 50 mg of graphene oxide (GO) was weighed and ultrasonically dispersed in 2 mL of deionized water, and ultrasonically treated for 2 h. At the same time, a 7M KOH solution was prepared, and 5 mL of a strong alkali solution was added to the dispersed graphene oxide slurry, and ultrasonic treatment was continued for 2 h. Transfer the mixed solution to a high-temperature ceramic container, and directly transfer it to a vacuum drying oven at 180°C for 1 h, then fully dissolve the obtained solid product in deionized water, and use a prepared 1M dilute hydrochloric acid solution for Neutralize until pH is around 7. The slurry obtained after neutralization was suction filtered and washed three times, and the obtained solid product was dried under vacuum at 50°C to obtain activated graphene oxide (AGO). 50 mg of activated graphene oxide was redispersed in 100 mL of deionized water, 2 mL of 80% hydrazine hydrate was added and refluxed for 20 h under the condition of 100 ° C oil b...

Embodiment 3

[0033] A 7M KOH solution was prepared and 50mg of graphene oxide (GO) was ultrasonically dispersed in 5mL of strong alkali solution, and ultrasonically treated for 2h. The mixed solution was transferred to a high-temperature ceramic container, and air-dried at 50°C until the surface of the slurry was wet. Transfer the wet slurry to a vacuum drying oven at 180°C for 1 hour, then fully dissolve the obtained solid product in deionized water, and use a prepared 1M dilute hydrochloric acid solution to neutralize to a pH of about 7. The slurry obtained after neutralization was suction filtered and washed three times, and the obtained solid product was dried under vacuum at 50°C to obtain activated graphene oxide (AGO). 50 mg of activated graphene oxide was redispersed in 100 mL of deionized water, 2 mL of 80% hydrazine hydrate was added and refluxed for 20 h under the condition of 100 ° C oil bath, the obtained product was subjected to suction filtration and washing, and dried under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com