Anode or cathode pole piece of lithium ion battery and coating method thereof

A lithium-ion battery and negative pole piece technology, which is applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrode manufacturing, etc., can solve problems such as easy powder drop of battery electrode pole pieces, high production raw material costs, and increased battery internal resistance , to achieve the effect of reducing powder shedding, improving market competitiveness and reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation of positive pole piece of lithium ion battery:

[0032] (1) Accurately weigh 100 grams of PVDF, 100 grams of conductive carbon black, and 1000 grams of NMP.

[0033] (2) The preparation of conductive adhesive, first, add 1000 grams of NMP into the vacuum mixer, then slowly add 100 grams of PVDF, stir, make PVDF dissolve completely, after mixing evenly, then add 100 grams of conductive carbon black, stir and mix evenly Make positive electrode conductive adhesive emulsion.

[0034] (3) Preparation of positive electrode material slurry: 94.5 grams of lithium cobaltate, 3.0 grams of conductive carbon black, 2.5 grams of PVDF and 50 grams of NMP were mixed evenly to prepare a positive electrode material slurry.

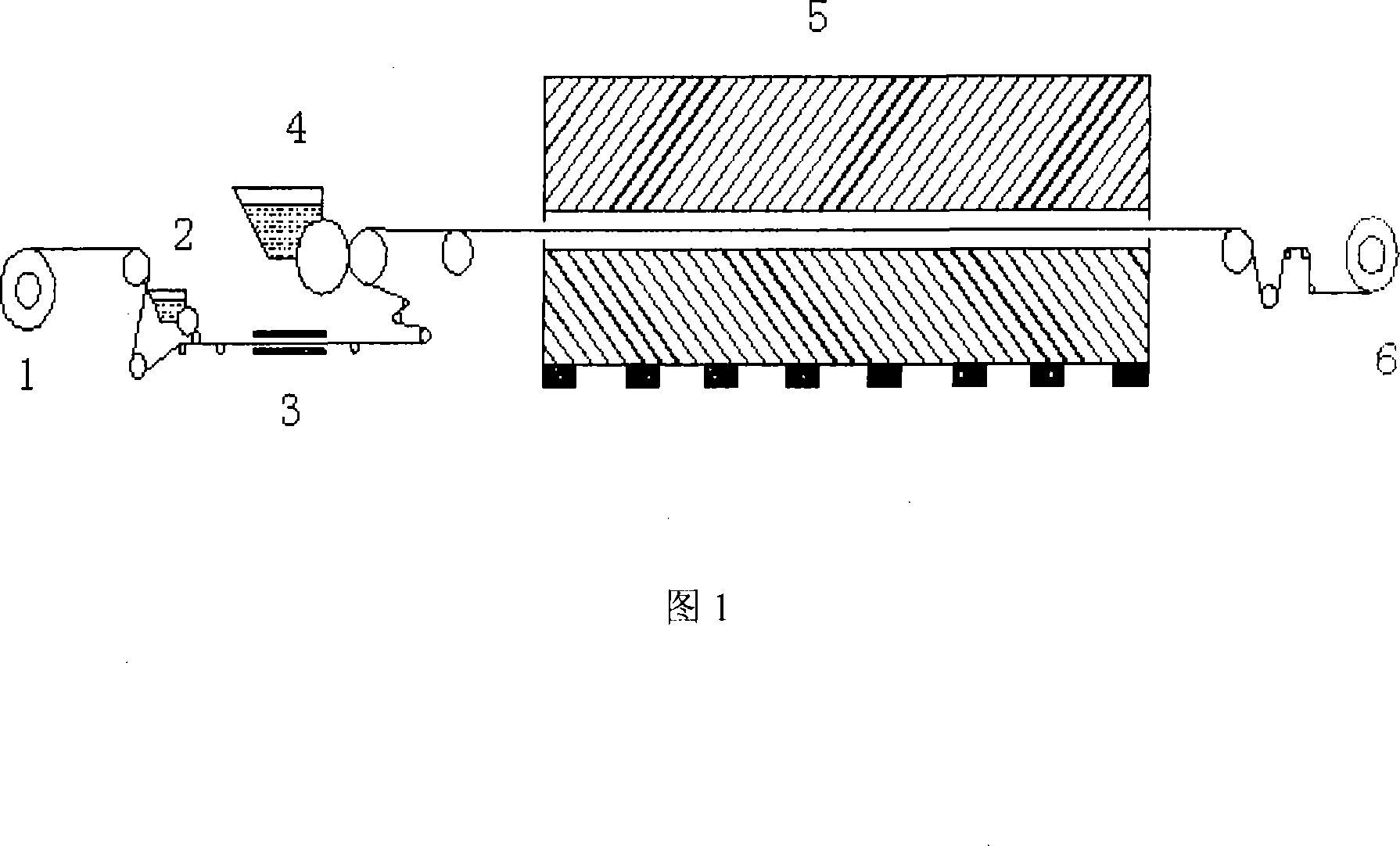

[0035] (4) Put the prepared conductive adhesive emulsion into the conductive adhesive tank 2 in Figure 1, install aluminum foil (thickness 0.018mm±0.002mm×width 260mm±1.0mm) on the unwinding device 1, and put the positive electrode material sl...

Embodiment 2

[0037] A kind of preparation of negative pole piece of lithium ion battery:

[0038] (1) Accurately weigh 50 grams of CMC, 100 grams of SBR emulsion, 100 grams of conductive carbon black, and 1000 grams of pure water.

[0039] (2) The preparation of conductive glue, at first, add 1000 grams of pure water in the vacuum mixer, then slowly add 50 grams of CMC, after stirring evenly, add 100 grams of SBR emulsion, after mixing evenly, then add 100 grams of conductive carbon black, Stir and mix evenly to make negative electrode conductive adhesive emulsion.

[0040] (3) Negative electrode material slurry preparation: 95.4 grams of artificial graphite, 1 gram of conductive carbon black, 1.6 grams of CMC, 2 grams of SBR and 100 grams of pure water were mixed evenly to prepare negative electrode material slurry.

[0041] (4) Put the prepared conductive adhesive emulsion into the conductive adhesive tank 2 in Figure 1, install copper foil (thickness 0.012mm ± 0.002mm × width 240mm ± 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com