Method for insulating AlGaN / GaN HEMT device

A device and substrate technology, applied in the field of microelectronics, can solve problems such as poor electrical isolation, material damage, and large leakage, and achieve good electrical isolation, avoid damage, and achieve good isolation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

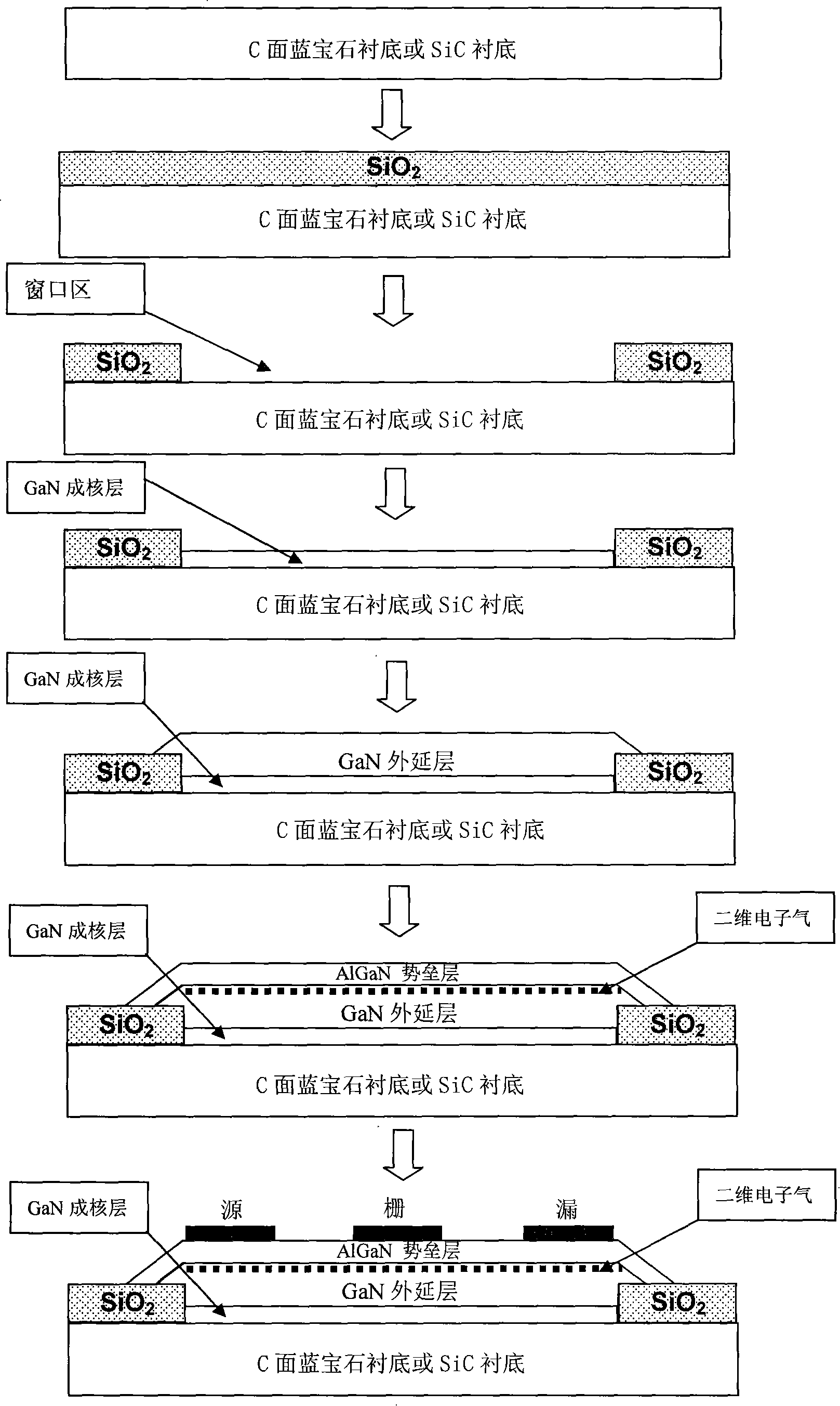

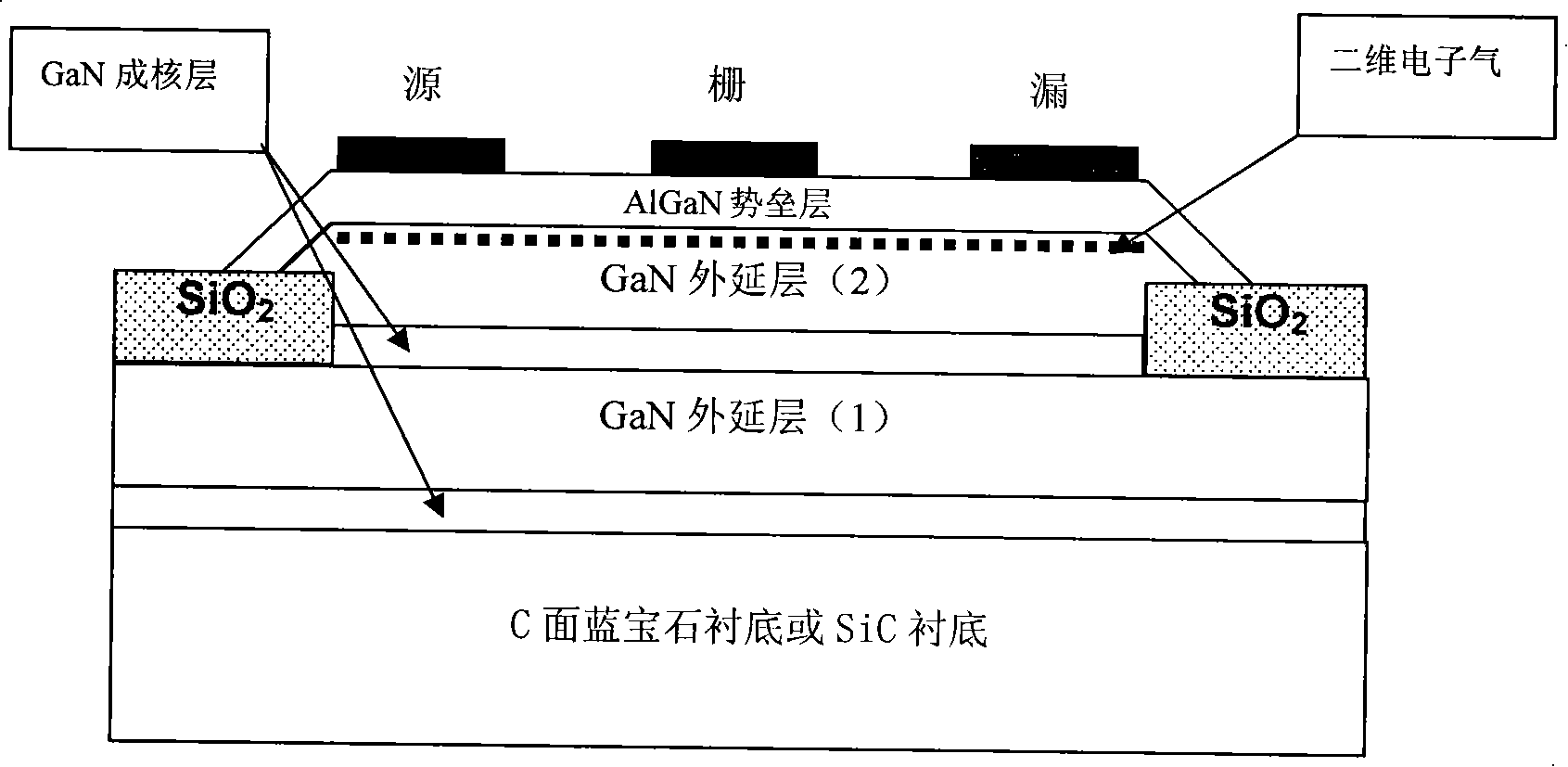

[0025] refer to figure 1 , which is a schematic diagram of the manufacturing process of an AlGaN / GaN HEMT device realized by the isolation method of the present invention. In the manufacturing process, the materials used are: the epitaxial materials are AlGaN and GaN; the substrate material is single crystal sapphire or SiC; the metal material It is Ti / Al / Ni / Au, Ni / Au; the dielectric material is SiO 2 . The process of making a device using the isolation method of the present invention is as follows:

[0026] 1. To Al 2 o 3 The substrate or SiC substrate uses PECVD equipment to deposit SiO with a thickness of about 250nm 2 Layer, PECVD deposition film formation RF frequency is 13.56MHz, power density is 0.011W / cm 2 , the substrate temperature is 350°C, and the reaction chamber pressure is 46.55Pa;

[0027] 2. Spin the glue on the sample at a speed of 5000 rpm, then bake in an oven at 80°C for 10 minutes, and form the window required for etching through photolithography an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com