Common grounding structure and use method thereof

A technology of public grounding and grounding bolts, which is applied in the direction of connection, connection contact materials, electrical components, etc., can solve the problems that the conductive contact surface is not easy to corrode, the conductive contact surface is easy to corrode, and the electrical performance is easy to age and decline, and it is not easy to achieve electrical performance. , Solve the influence of electrical properties, reduce the effect of aging and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

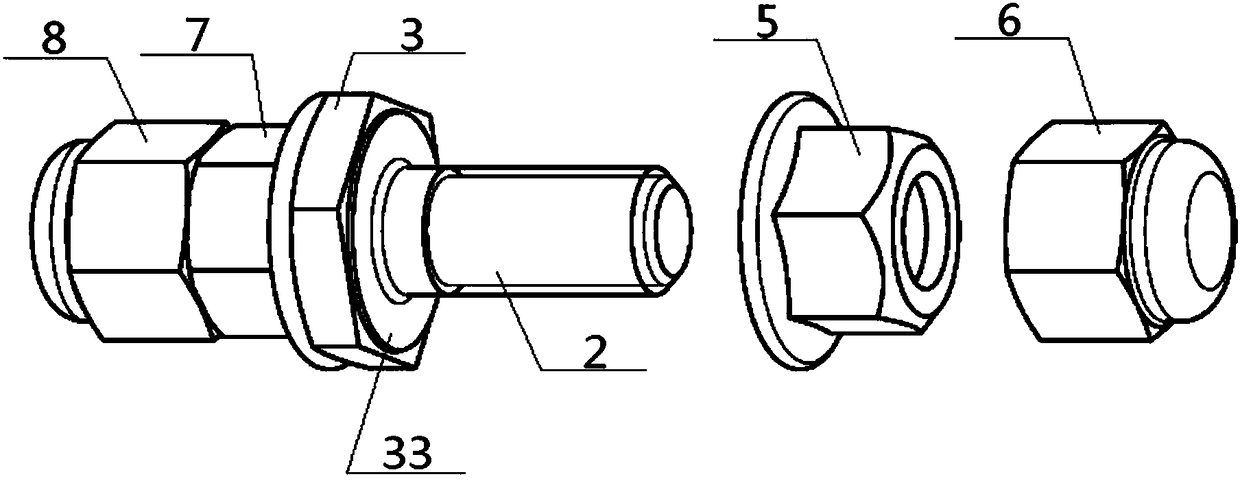

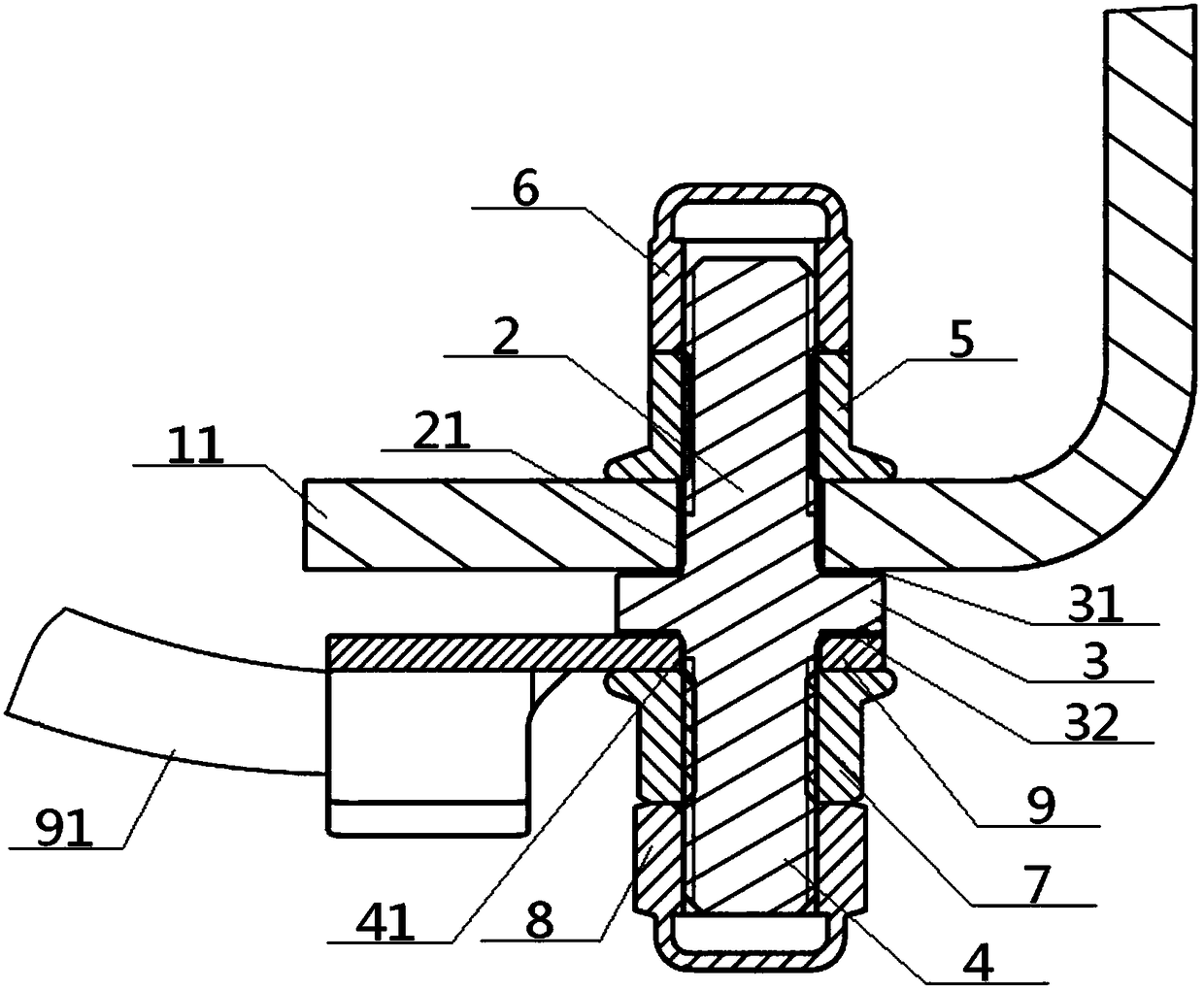

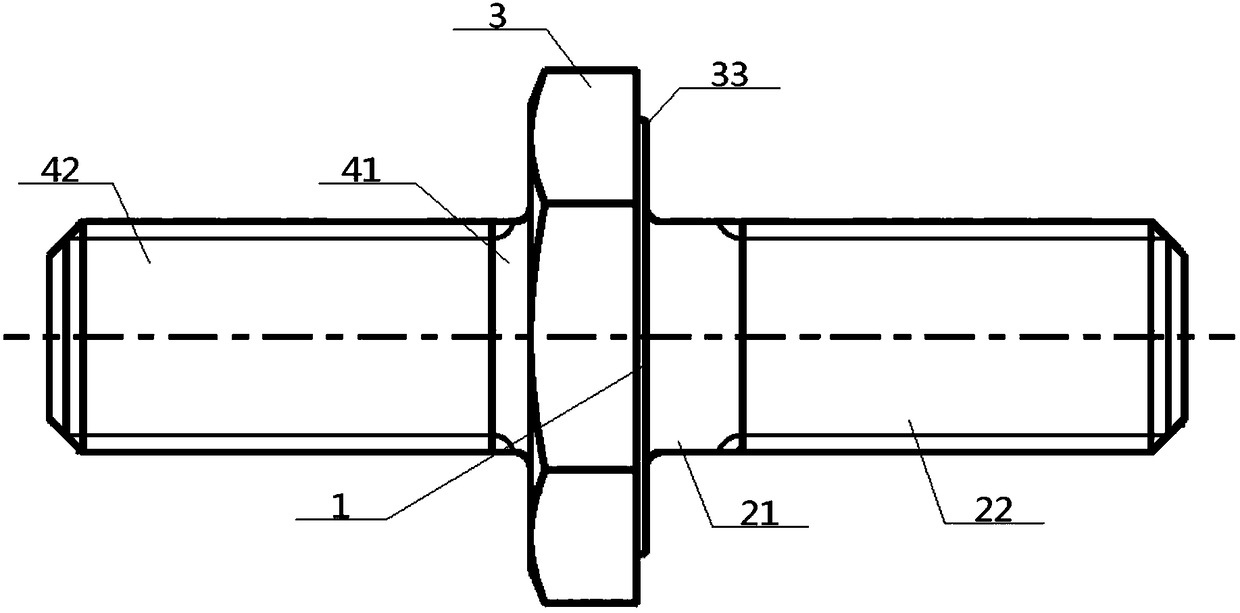

[0052] see Figure 1 to Figure 5 , a common grounding structure, including a mounting part, a wiring part and a terminal fixing part, one end of the mounting part is connected to the common grounding point 11, the other end of the mounting part is connected to one end of the connecting part, and the other end of the connecting part The terminal fixing part is connected with the negative line terminal 9; the installation part includes a mounting stud 2, the wiring part includes a connecting stud 4, the terminal fixing part includes a connecting nut 7, and the inner part of the mounting stud 2 The end is connected to the inner end of the boss 3 and the terminal stud 4 to form a double-headed grounding bolt 1 of an integrated structure. The side of the column 4 is the wiring conductive contact surface 32; the outer circumference of the mounting stud 2 is threadedly connected with the mounting nut 5 sleeved on the outside of the mounting stud 2, and the external extension of the m...

Embodiment 2

[0058] Basic content is the same as embodiment 1, the difference is:

[0059] The production of the grounding kit is carried out at the parts supplier, the production of the common grounding part is carried out at the production and assembly plant of the public grounding part, and the wiring assembly is carried out at the general assembly plant of the whole machine / vehicle.

Embodiment 3

[0061] Basic content is the same as embodiment 1, the difference is:

[0062] The diameters of the common conductive contact surface 31 and the wiring conductive contact surface 32 are both greater than or equal to the diameter of the negative wire terminal 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com