Polymer/metal composite fibers and preparation method thereof

A metal composite and metal short fiber technology, applied in the direction of conductive/antistatic filament manufacturing, stretch spinning, single-component polyester rayon, etc., can solve the problem of no increase in elongation at break and the specific gravity of the core metal Increased fiber density and other problems, to achieve the effects of wide applicability, improved processability, and increased production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

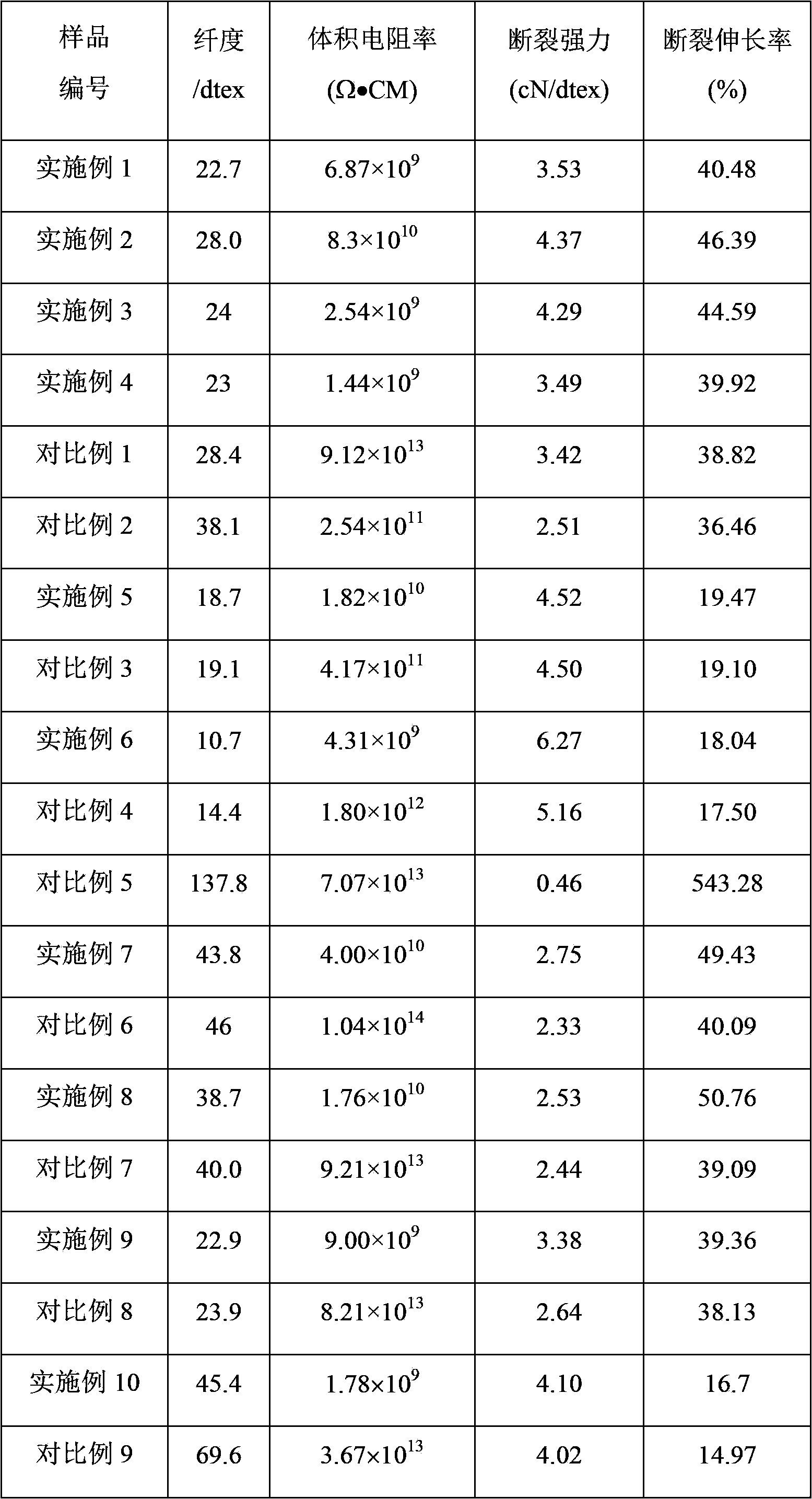

Examples

Embodiment 1

[0042] The polymer in this example is polypropylene (Sinopec Ningbo Zhenhai Refining & Chemical Co., Ltd., grade Z30S, melting point 167°C), the metal alloy is tin-bismuth alloy (melting point 138°C), and the volume ratio of tin-bismuth alloy to polypropylene is 2:100 , adding an appropriate amount of antioxidant 1010 (produced by Ciba-Geigy, Switzerland), antioxidant 168 (produced by Ciba-Geigy, Switzerland) and zinc stearate (commercially available); wherein the polypropylene is 100 parts by weight, the anti-oxidant Oxygen 1010 is 0.5 part, antioxidant 168 is 0.5 part, and zinc stearate is 1 part.

[0043] Mix uniformly in a high-speed mixer according to the above-mentioned raw materials and proportions of the polymer and the metal alloy. After that, extrude and granulate with the PolymLab twin-screw extruder of German HAAKE company. The temperature of each section of the extruder is: 190°C, 200°C, 210°C, 210°C, 210°C, 200°C (head temperature). The pellets were put into a c...

Embodiment 2

[0046] Except that the volume ratio of the metal alloy to the polymer was 0.5:100, the rest were the same as in Example 1. The obtained polymer / metal composite fiber was subjected to various tests, and the test results are listed in Table 1. Observed by an optical microscope, the diameter of short metal fibers in the composite fiber is less than 1.04 μm, and the length is greater than or equal to 4.12 μm.

Embodiment 3

[0048] Except that the volume ratio of the metal alloy to the polymer was 1:100, the rest were the same as in Example 1. The obtained polymer / metal composite fiber was subjected to various tests, and the test results are listed in Table 1. Observed by an optical microscope, the diameter of short metal fibers in the composite fiber is less than 2.15 μm, and the length is greater than or equal to 4.94 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com