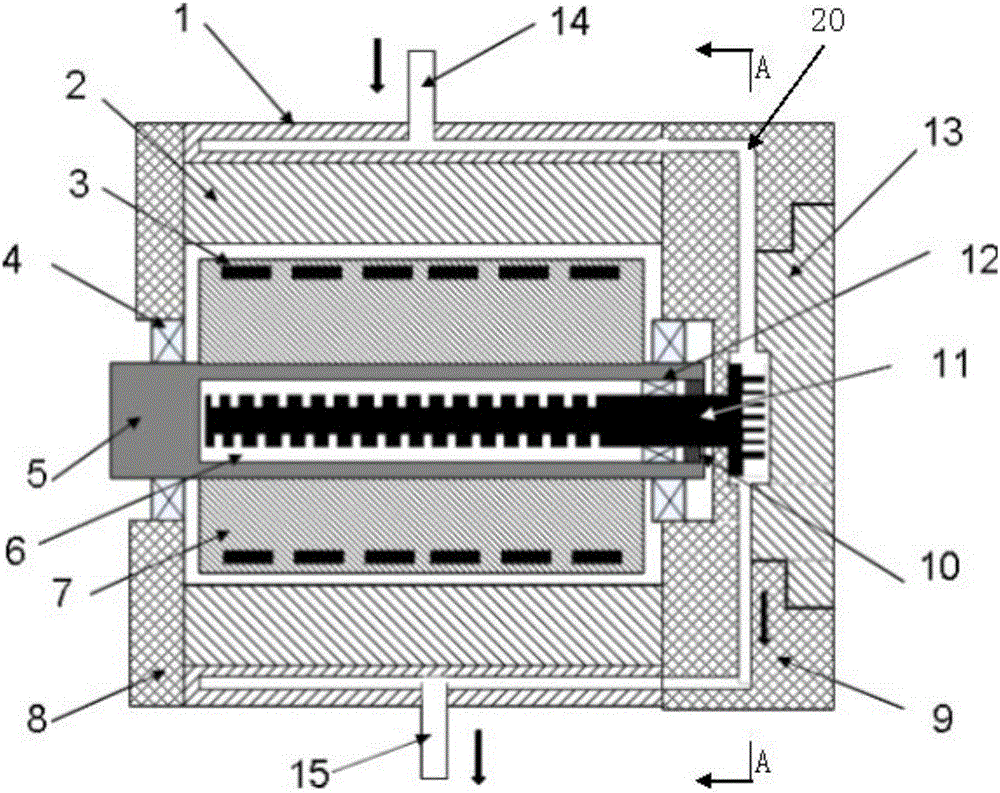

Cooling structure of inner rotor motor

An inner rotor motor and cooling structure technology, applied in cooling/ventilation devices, magnetic circuit shape/style/structure, electromechanical devices, etc. The effect of cooling effect is satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

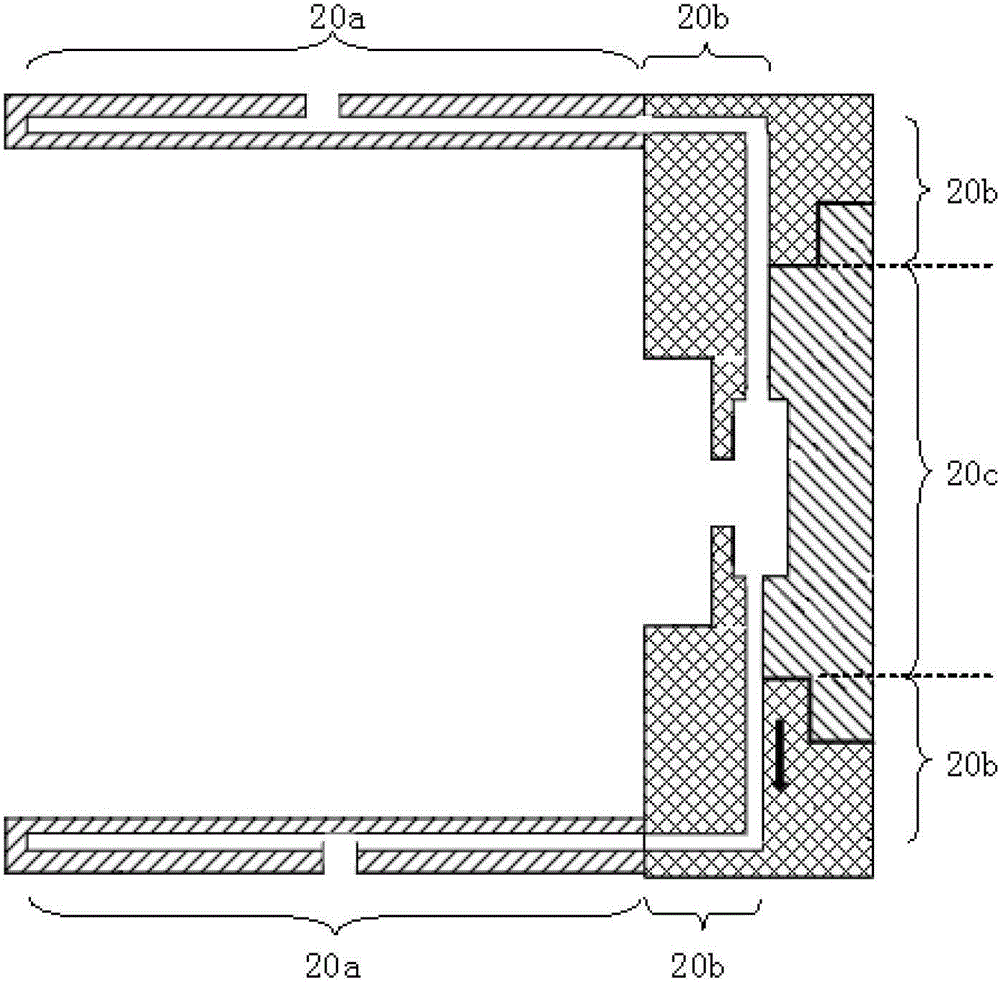

[0053] The shape of the third cavity 20c of the second embodiment can be the same as that of the first embodiment, such as Figure 2d Shown; It can also be only a simple tubular shape, so as to be connected with the second cavity 20b.

[0054] In the above two embodiments, the separation design of the cover 13 and the front cover 9 is mainly for the convenience of assembling the heat conducting rod 11 . Alternatively, the cover 13 and the front end cover 9 can also be integrated, and at this time the second cavity and the third cavity are both in the integrated front end cover.

[0055] The technical advantages of the cooling structure of the inner rotor motor described in the above two embodiments are:

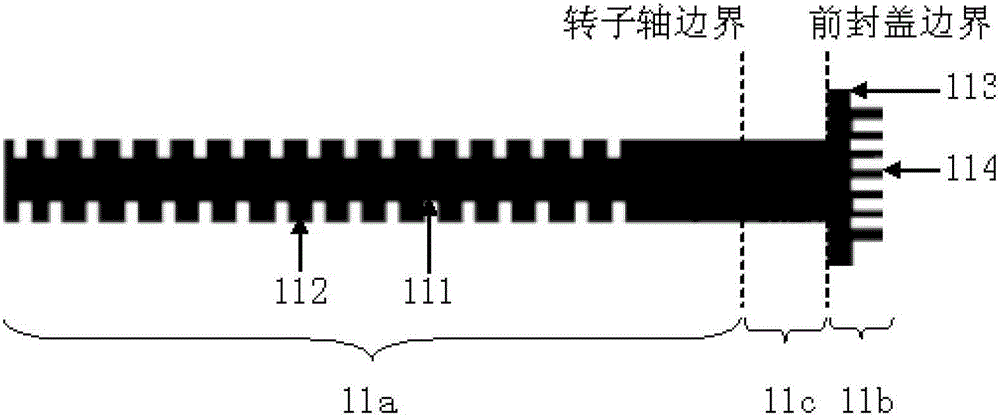

[0056] 1. Avoid the hidden danger of short circuit inside the motor. This is because the heat conduction chamber 6 is filled with non-conductive heat conduction oil, even if the dynamic seal between the rotor shaft 5 and the heat conduction rod 11 fails slightly, a small am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com