Tab pole piece and winding battery

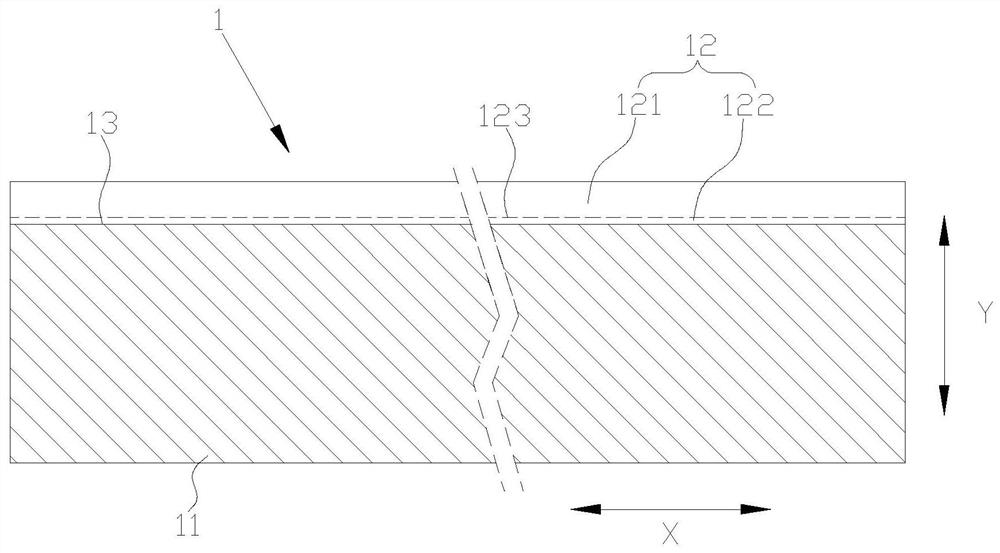

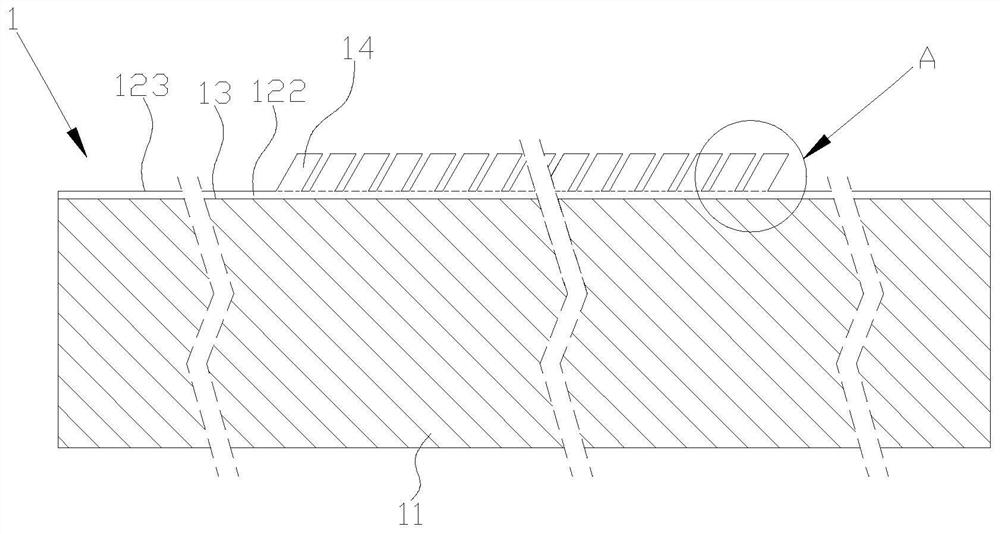

A technology of tabs and pole pieces, which is applied in the direction of secondary batteries, battery pack components, non-aqueous electrolyte battery electrodes, etc., can solve the problem of reducing the performance of wound batteries, deformation of internal pole pieces, active materials of positive and negative pole pieces, etc. Problems such as shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

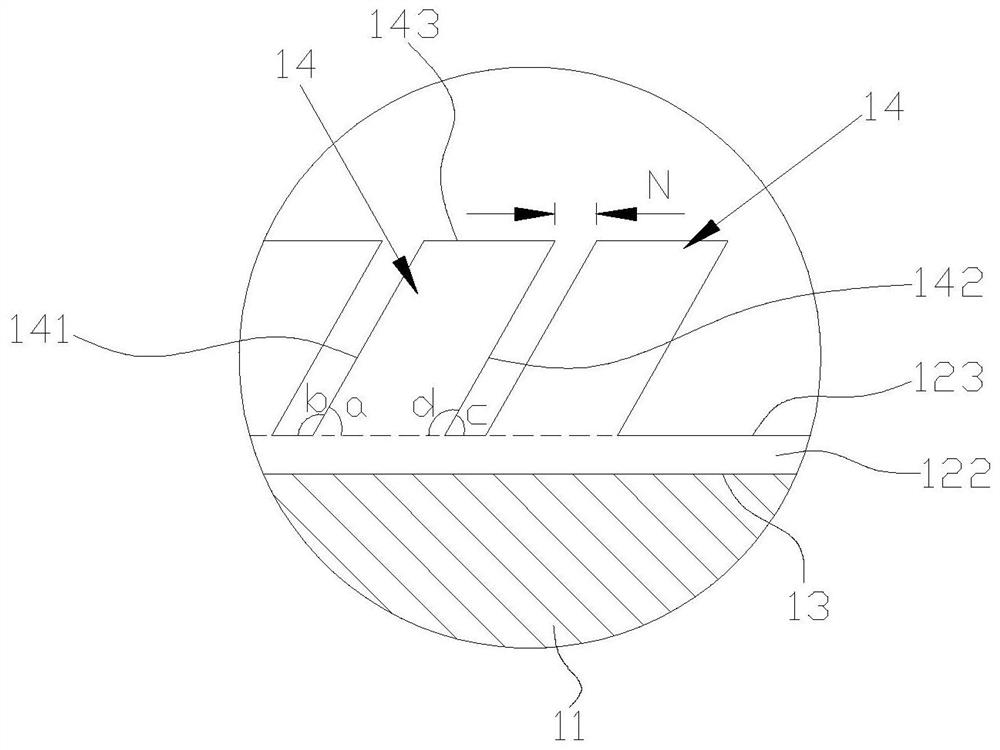

[0058] As an embodiment, the wound battery further includes a second separator 24, and the positive tab tab 21, the first diaphragm 23, the negative tab tab 22, and the second diaphragm 24 are stacked sequentially from the inside to the outside. The latter form the battery core 2 by winding after lamination.

[0059] As an embodiment, the distance between the tab 211 on the positive tab tab 21 and the top of the first diaphragm 23 is 0.5-5 mm after smoothing, and the tab 221 on the tab tab 22 on the negative tab is smoothed. The distance beyond the bottom end of the first diaphragm 23 is less than 5 mm.

[0060] As another embodiment, the tab 211 on the positive tab tab 21 exceeds the top of the first diaphragm 23 by less than 3mm after being smoothed, and the tab 221 on the negative tab tab 22 exceeds the distance after smoothing. The distance between the bottom ends of the first diaphragm 23 is less than 3mm.

[0061] As another embodiment, the distance of the tab 211 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com