Pole sheet roll forming method and device

A roll forming and pole piece technology, applied in the field of pressure forming, can solve problems such as deterioration of rate performance and low temperature cycle performance, reduction of electrochemical performance of battery cells, increase of pole piece thickness, etc., so as to improve production efficiency and facilitate absorption. And the effect of wetting and reducing roller pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The pole piece roll forming method and device according to the present invention will be described in detail below with reference to the accompanying drawings.

[0024] Firstly, the pole piece roll forming method according to the first aspect of the present invention will be described.

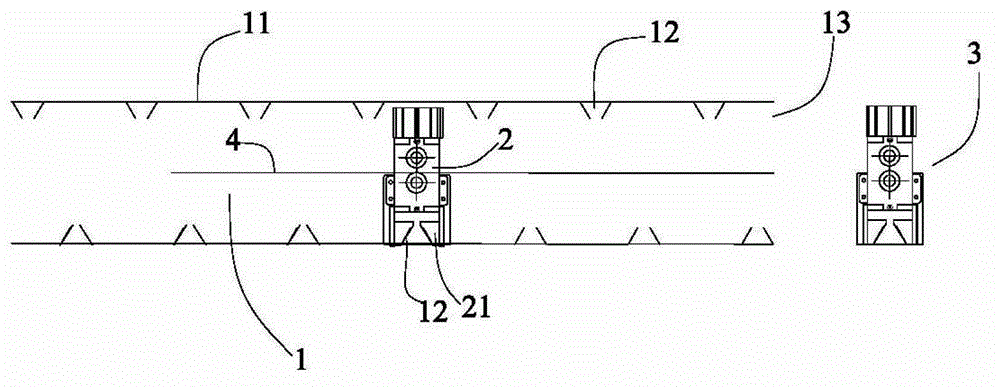

[0025] refer to figure 1 According to the pole piece roll forming method of the present invention, the method includes the steps of: coating the slurry on the surface of the current collector to make the pole piece 4; the pole piece 4 enters the coating machine oven 1 and is dried; the dried The pole piece 4 is pulled into the rolling mechanism 2 for rolling; wherein, the drying treatment of the pole piece 4 and the rolling of the rolling mechanism 2 are both carried out in the oven 1 of the coating machine.

[0026] Since the pole piece 4 is gradually dried from the outside to the inside during the drying process, the pole piece 4 can be rolled by selecting the position where the pole...

PUM

| Property | Measurement | Unit |

|---|---|---|

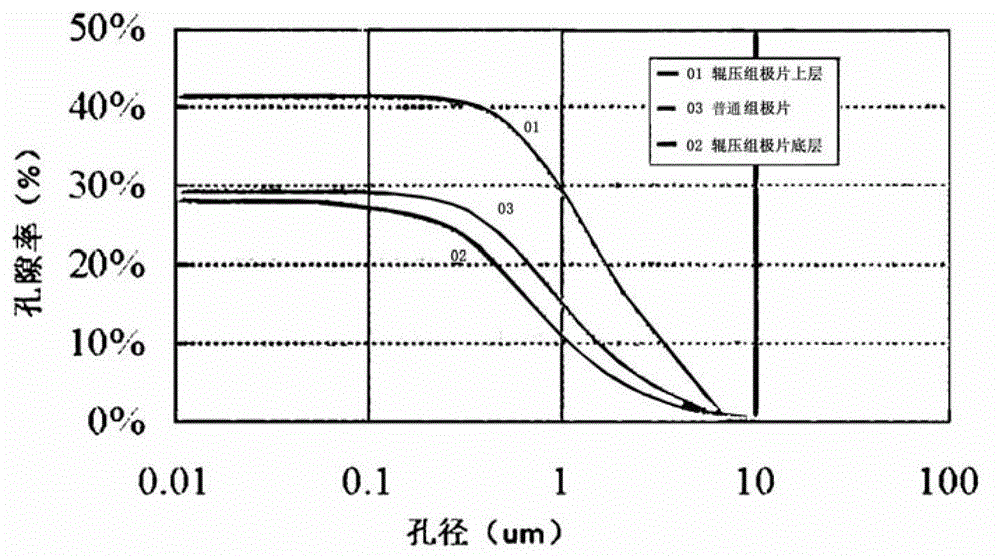

| porosity | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com