Sulfide solid electrolyte stable to lithium, preparation method thereof and solid-state battery with solid electrolyte

A solid electrolyte and solid-state battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as explosion, unusable, spontaneous combustion, etc., and achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

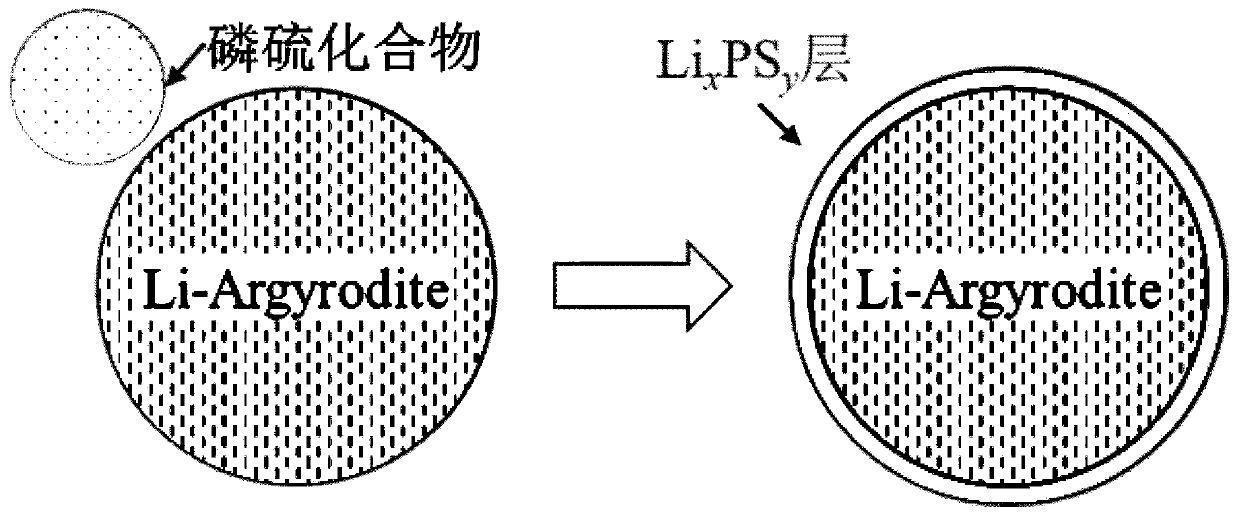

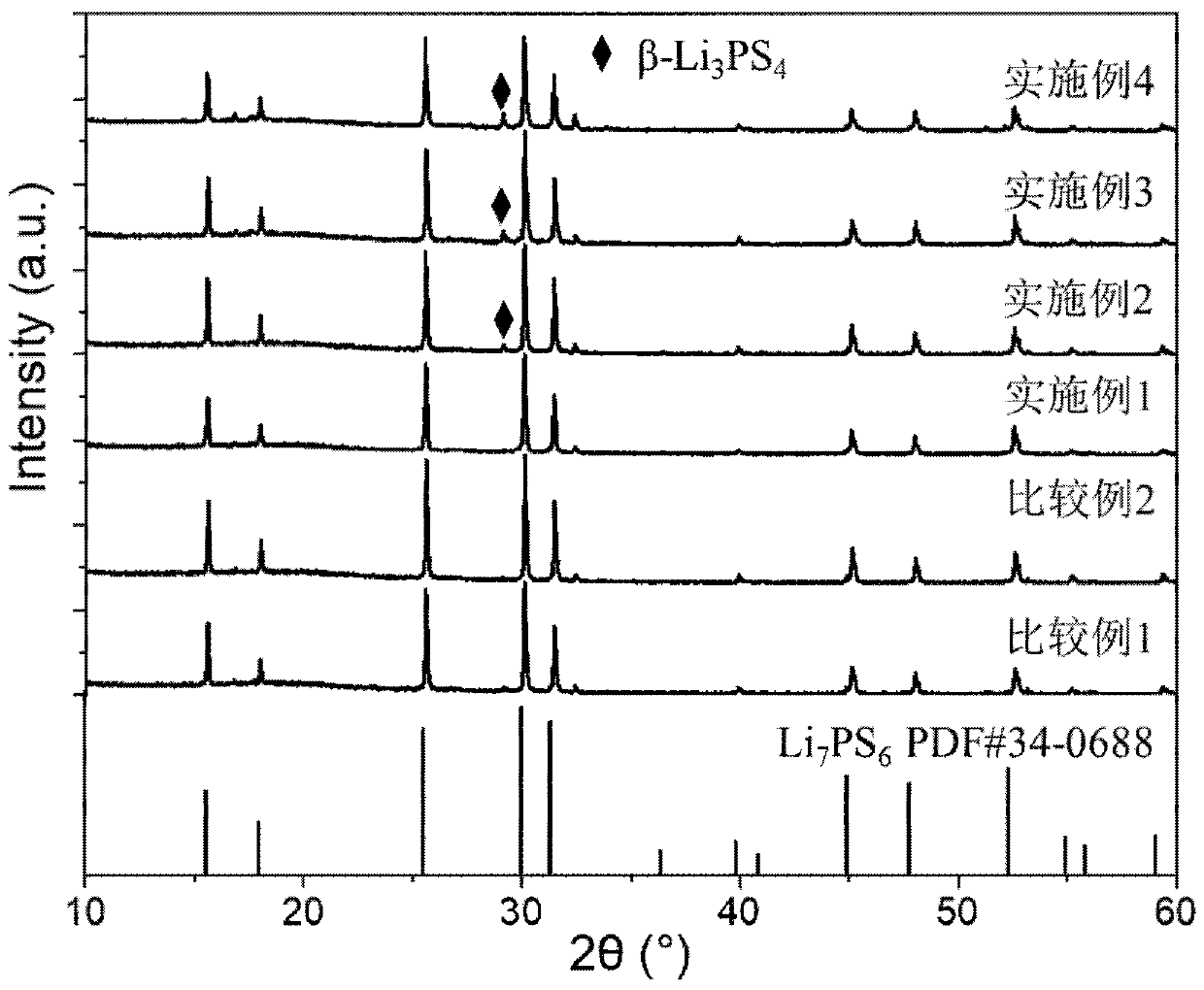

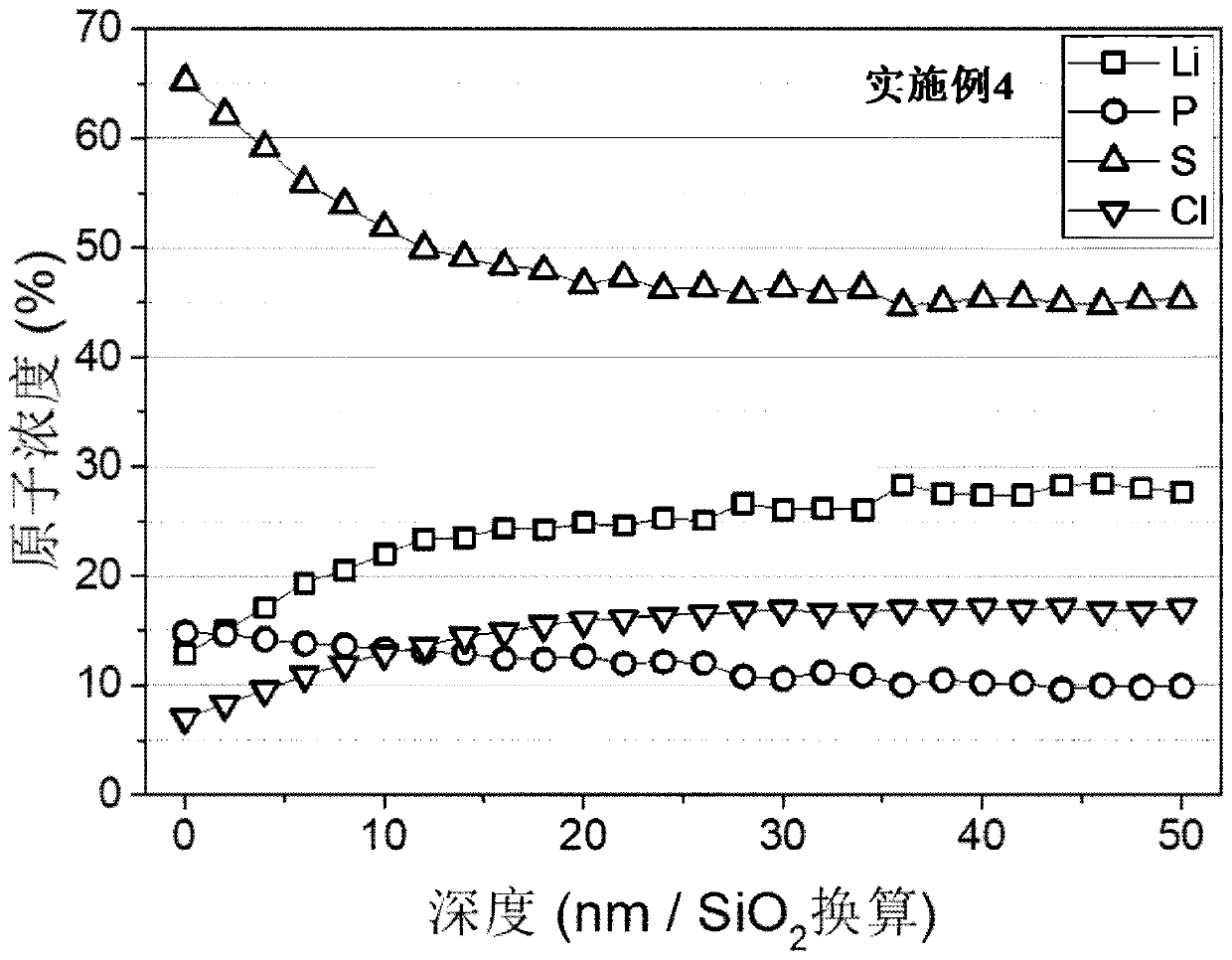

[0048] Gained Li in 2g comparative example 1 6 P.S. 5 Cl with 0.0331g P 2 S 5 (2mol%) into a 50mL agate-lined ball mill jar, add 50g of zirconia grinding medium balls with a diameter of 5mm, and mix evenly with a planetary ball mill at a speed of 250rpm under the condition that the water content is less than 10ppm, then take out the powder and pass through a 100-mesh sieve net, placed in an electric furnace, and heat-treated at 270 ° C for 4 hours to prepare the Li-Argyrodite electrolyte material of Example 1 with a core-shell structure, as shown in the attached figure 1 shown.

Embodiment 1b

[0050] The wet grinding method can also be used here, such as the obtained Li in 2g Comparative Example 1 6 P.S. 5 Cl with 0.0331g P 2 S 5 (2mol%) into a 50mL agate-lined ball mill jar, add 50g of zirconia grinding media balls with a diameter of 5mm and 6g of n-heptane, mix evenly with a planetary ball mill at a speed of 250rpm under the condition that the water content is less than 10ppm, and then take out the slurry , Dry at 80-120°C to obtain powder. Pass through a 100-mesh sieve, place in an electric furnace, and heat-treat at 270° C. for 4 hours to prepare the Li-Argyrodite electrolyte material of Example 1a with a core-shell structure. Both methods can obtain core-shell structure electrolyte particles with similar properties, and the test is based on Example 1a.

Embodiment 2

[0052] Gained Li in 2g comparative example 1 6 P.S. 5 Cl with 0.0662g P 2 S 5 (4mol%) into a 50mL agate-lined ball mill jar, add 50g of zirconia grinding medium balls with a diameter of 5mm, mix evenly with a planetary ball mill at a speed of 250rpm under the condition that the water content is less than 10ppm, take out the powder, and pass through a 100-mesh sieve The mesh was placed in an electric furnace and heat-treated at 270° C. for 4 hours to prepare the Li-Argyrodite electrolyte material of Example 2 with a core-shell structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com