High power motor over-voltage protection device

A protection device and overvoltage technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve problems such as fatigue damage, motor, electric arc furnace transformer damage, loss of vacuum switch, motor and transformer protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

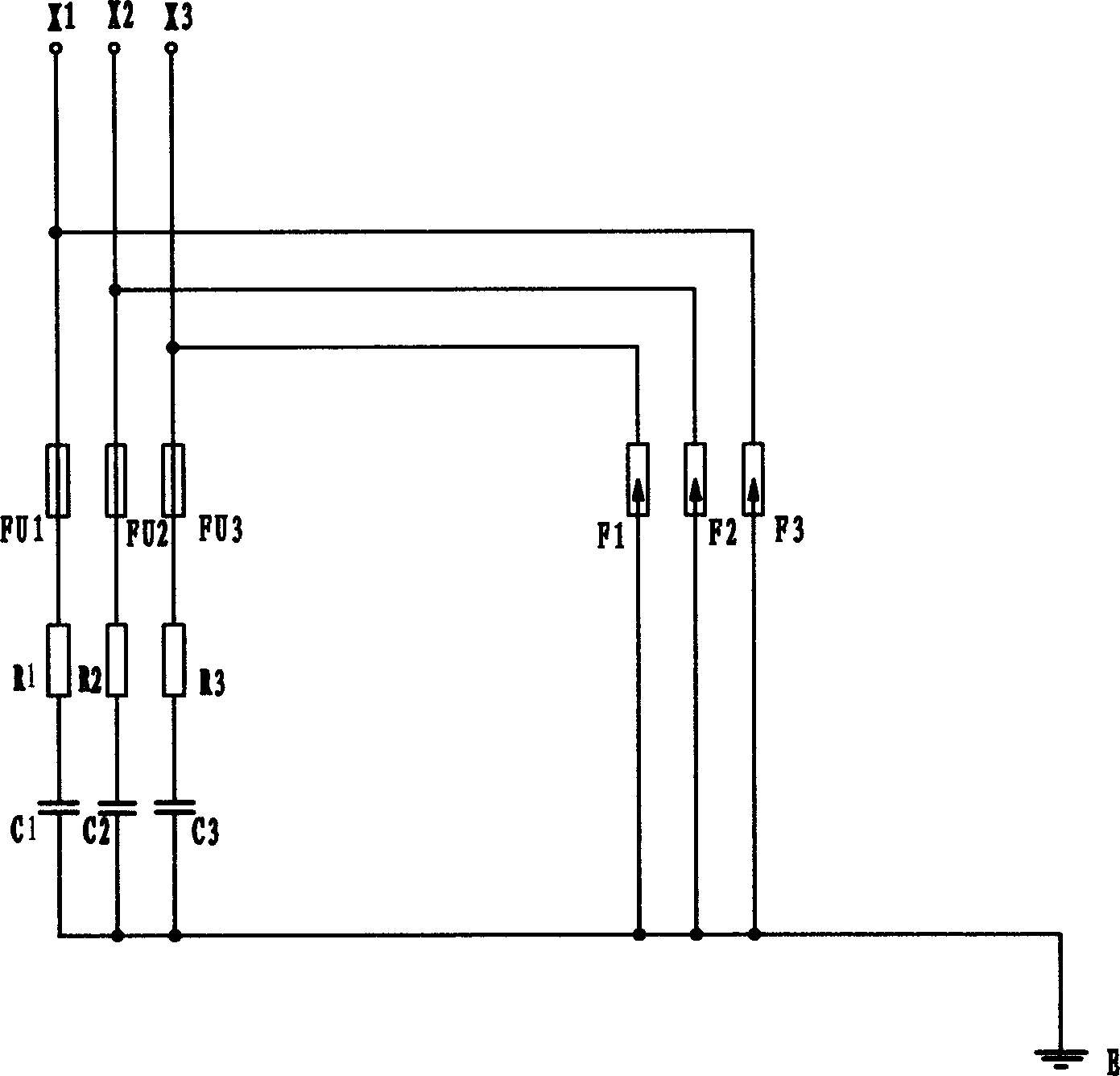

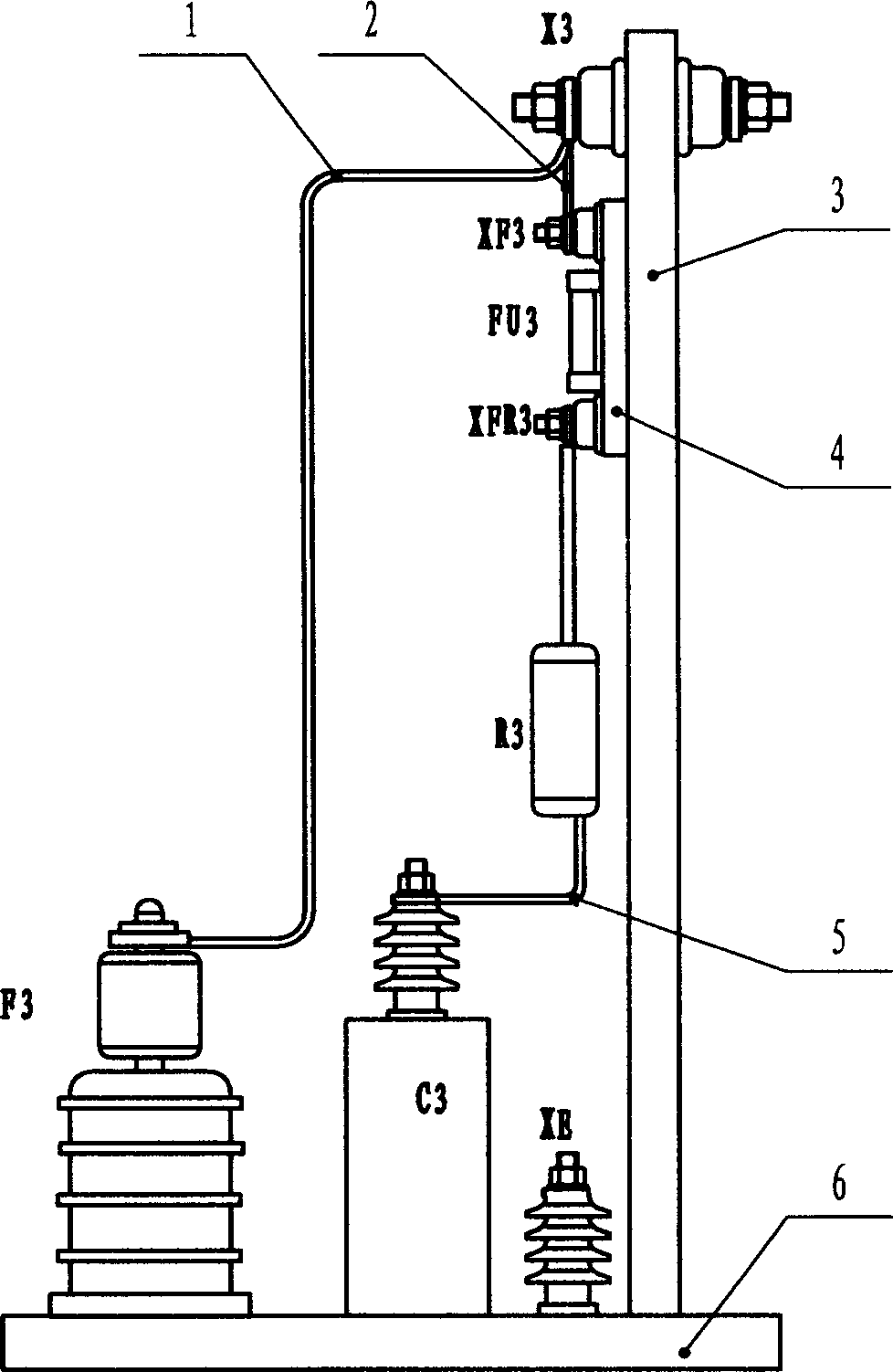

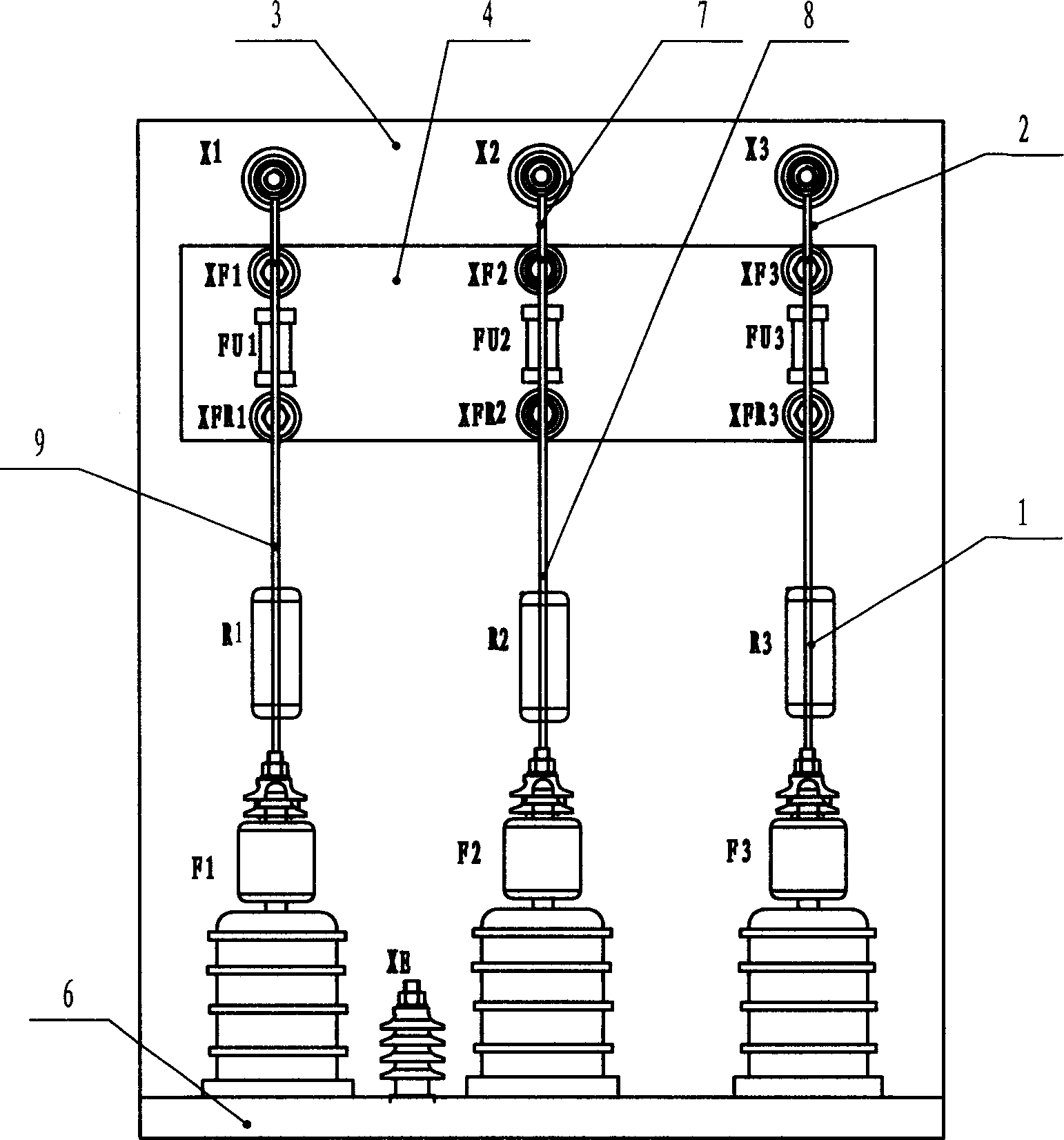

[0027] figure 1 , figure 2 and image 3 The described high-power motor overvoltage protection devices include zinc oxide arrester F1, zinc oxide arrester F2 and zinc oxide arrester F3, the negative poles of the three zinc oxide arresters are connected to the terminal XE for grounding, zinc oxide arrester F1, zinc oxide arrester F2, the positive electrode of the zinc oxide arrester F3 is connected to the terminal X1, the terminal X2, and the terminal X3 respectively with the lead wire such as lead 9, which is characterized in that three groups of resistors corresponding to the three-phase electricity are connected in series with the capacitor R-C resistance container, take R3-C3 resistance container as an example to illustrate the connection of R-C resistance container, Electricity Negative pole of container C3 Connect with terminal XE, the positive pole of capacitor C3 is connected with one end of resistor R3, the other end of resistor R3 is connected with one end of fus...

Embodiment 2

[0032] The circuit diagram of this embodiment and the connection entity diagram of the corresponding electrical components are shown in figure 1 , figure 2 , the rated voltage of the power supply in this embodiment is 12KV, the rated capacitances of capacitor C1, capacitor C2 and capacitor C3 are all 0.10μF±10%, and the rated resistance values of resistor R1, resistor R2 and resistor R3 are all 100Ω± 10%, the technical parameters of zinc oxide arrester F1, zinc oxide arrester F2, and zinc oxide arrester F3 are all in the second line of Table 2 (the system rated voltage is 10KV).

[0033] This embodiment can be used as a configuration device for a high-power electric arc furnace power supply transformer, see Figure 4 and Figure 5 , the rated capacity of the air switch is 800-1250A, and the rated capacity of the transformer T is 5500-6000KVA.

[0034] This embodiment can also be used as a configuration device for a high-power motor, and the connection with the motor M an...

Embodiment 3

[0036] The circuit diagram of this embodiment and the connection entity diagram of the corresponding electrical components are shown in figure 1 , figure 2, the rated power supply voltage of this embodiment is 40.5KV, the rated capacitance of capacitor C1, capacitor C2 and capacitor C3 is 0.05μF±10%, and the rated resistance value of resistor R1, resistor R2 and resistor R3 is 100Ω± 10%, the technical parameters of zinc oxide arrester F1, zinc oxide arrester F2, and zinc oxide arrester F3 are all in the fourth row in Table 2 (the system rated voltage is 35KV).

[0037] This embodiment can be used as a configuration device for a high-power electric arc furnace power supply transformer, see Figure 4 and Figure 5 , the rated capacity of the air switch is 1000-4000A, and the rated capacity of the transformer T is 40-150MVA. This embodiment can also be used as a configuration device for a high-power motor, and the connection with the motor M and the air switch Q1 is shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com