Novel quick blasthole sealant

A sealing agent and a new type of technology, applied in blasting and other directions, can solve the problems of blind guns, difficult to deal with blind guns, and wear of gunpowder leads, so as to ensure the construction efficiency, shorten the waiting time, and improve the construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

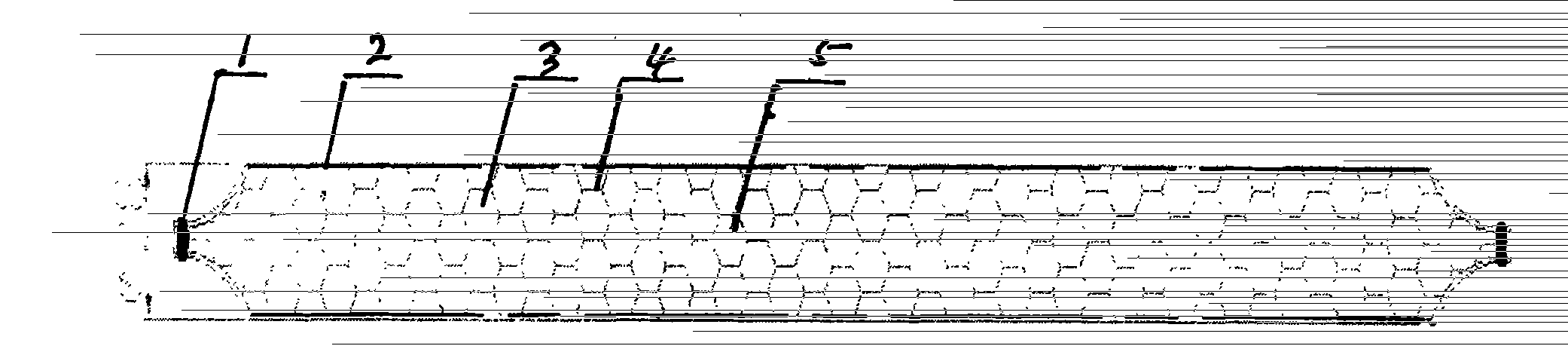

[0013] As shown in the accompanying drawing, the new rapid blasthole sealing agent has a structure of composite membrane material, a cylindrical blasthole sealing shell 2 with a diameter of 28mm and a length of 400mm, filled with barriers in the cylindrical blasthole sealing shell. Combustion agent 3, dust suppressant 4, and binder 5 are used to seal the two ends of the cylindrical blast hole sealing shell with aluminum card materials to form a cone 2.

[0014] First, mix the flame retardant 3, dust suppressant 4, and binder 5 evenly, and use a filling machine to pour them into the prepared composite film cylinder blasthole sealing shell 2, and then use aluminum clips to clamp both ends. Tight, the assembly is completed, and different specifications can be made according to different requirements.

Embodiment 2

[0016] Drill holes according to the hole diameter and depth required by the design, and use a blower to clean up the floating or accumulated water in the holes. After the gunpowder is tied to the lead wire, it is sent into the bottom of the blast hole with a gun stick. According to the depth of the blast hole, a new type of rapid blast hole sealing agent is inserted into the blast hole and tamped with a gun stick. At the outermost end, you can use 100mm - 150mm clay gun soil for compaction, or directly tear the outer package of the new rapid blast hole sealing agent according to actual needs, and use a gun stick for compaction to ensure a better blasting effect.

[0017] Even if you encounter a blind gun during use, it is easy to handle due to its one-piece feature. You only need to hook the aluminum card to pull it out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com