Method and device for improving MCVD deposition efficiency and quality of low-temperature refrigeration

A technology of deposition efficiency and low-temperature gas, which is applied in glass deposition furnaces, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of low deposition efficiency and loss, and achieve the effects of low refrigeration temperature, easy operation, and easy temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

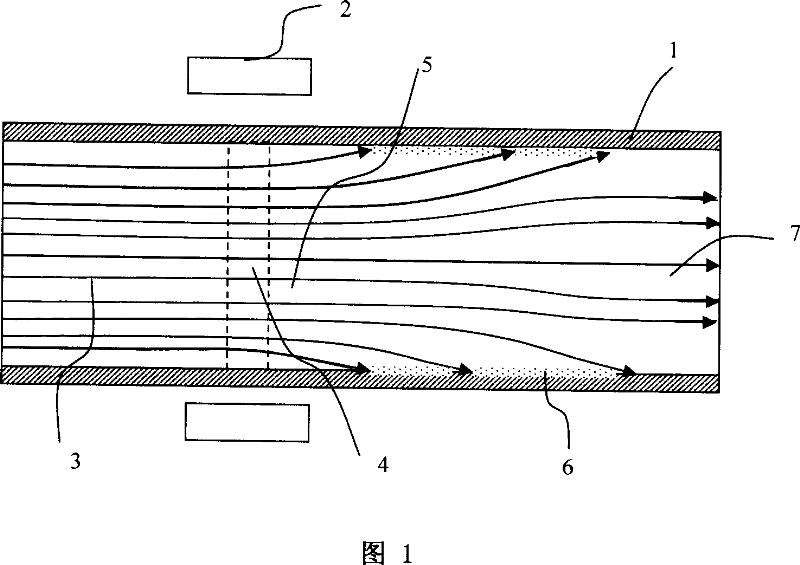

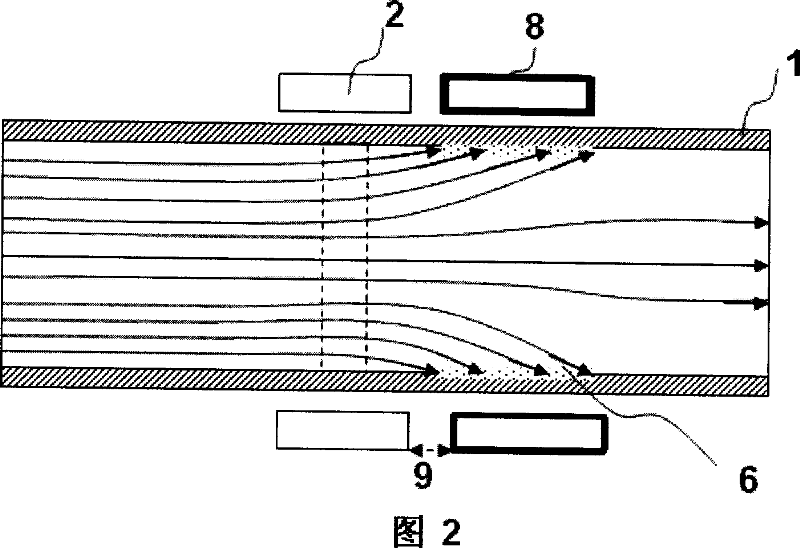

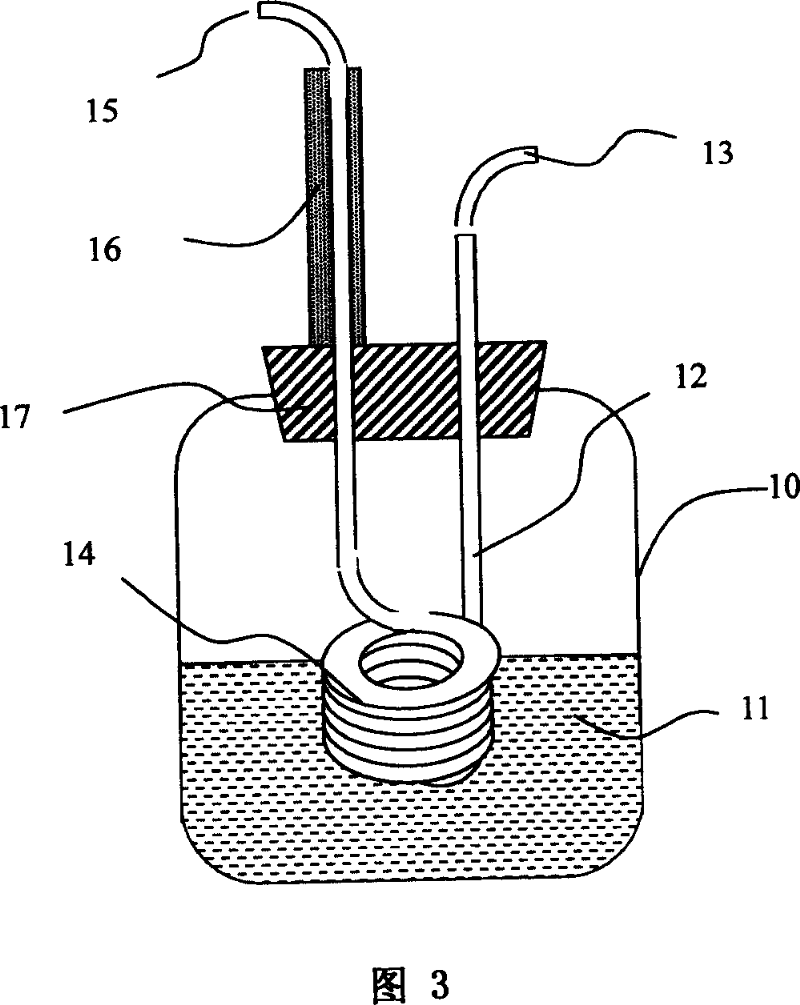

[0028] The specific embodiment of the present invention will be described in detail below in conjunction with accompanying drawing 1-7:

[0029] The low-temperature blowing gas adopts high-purity inert gas, such as argon, nitrogen and helium, to avoid the influence on the heating area. Refrigerant gas (helium, argon or nitrogen) is output from a steel cylinder (or other gas source) through a pressure reducing valve to adjust the pressure and is controlled by a flowmeter. The gas temperature at this time is basically room temperature. The refrigerated gas output by the flowmeter is input into the low-temperature-resistant heat-conducting stainless steel pipe (12), and enters the heat-insulating container (10) filled with low-temperature cooling medium liquid nitrogen or other low-temperature substances (11) through the stainless steel pipe. In order to make the refrigerant gas fully cool down, the stainless steel pipe in the container is bent into a spiral (14) and submerged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com