Dyeing wet steaming process

A process, wet steaming technology, applied in the field of dyeing wet steaming, can solve the problems of high energy consumption, pollution, long dyeing process flow, low color fixing rate, etc., and achieve the effect of ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

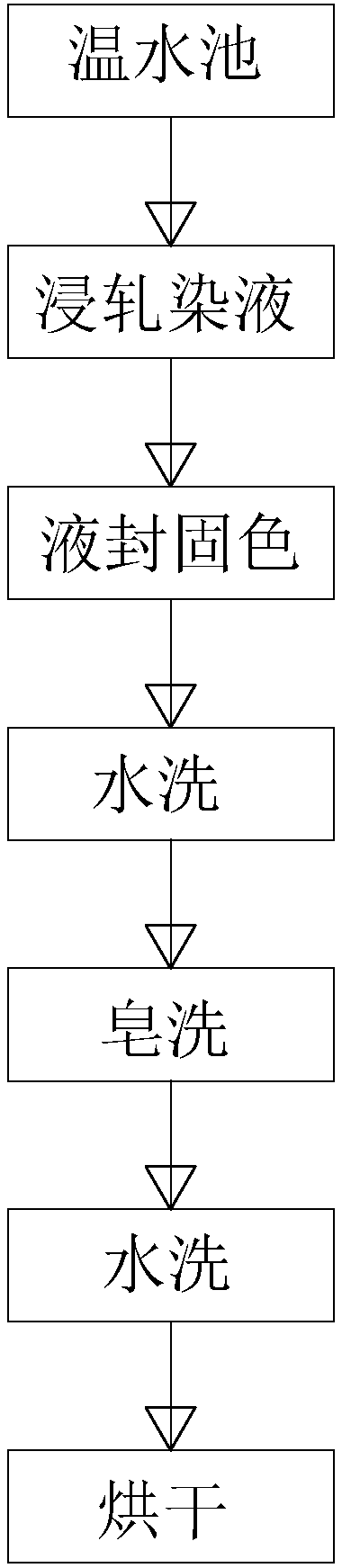

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] The dyeing wet steaming process is as follows;

[0035] 1. Put the fabric to be processed into the warm water pool for water to make the fabric moist. The optimal temperature of the warm water pool is controlled at 60°C;

[0036] 2. Transfer the wet fabric into the pad dyeing machine and soak it in the pad dyeing solution. The components of the pad dyeing solution include 20-100g / l of reactive dye, 20g / l of sodium sulfate, and 2g / l of diffusing agent. Soda ash 25 g / l, ECO penetrant 10ml / l, urea 50g / l, anti-swifting agent 5g / l (the square-swimming agent is seaweed sodium paste) and anti-staining salt S 5g / l; reactive dyes include reactive red K2G 5g / l, active orange KGN 10g / l and active brown KB3R 12g / l; the padding temperature is room temperature and the liquid rate is controlled at 80%, the water used in the padding liquid is soft water and the liquo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com