Method for casting high-quality aluminum part through chips of aluminum-silicon pistons

An aluminum-silicon-based, high-quality technology, which is applied in the field of casting high-quality aluminum parts using aluminum-silicon-based piston chips, can solve the problems of aluminum chip oxidation corrosion and waste of raw materials, and achieve the effect of reducing oxidation burning loss and satisfying mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

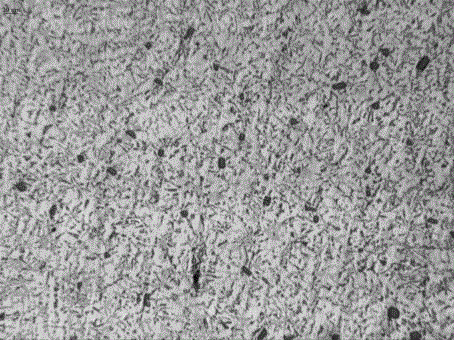

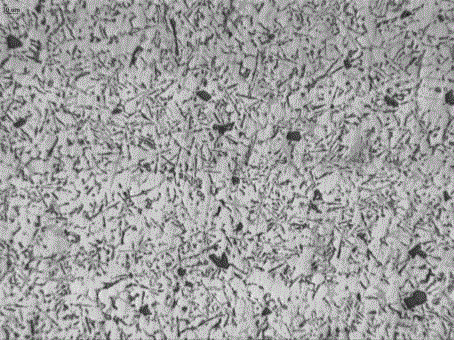

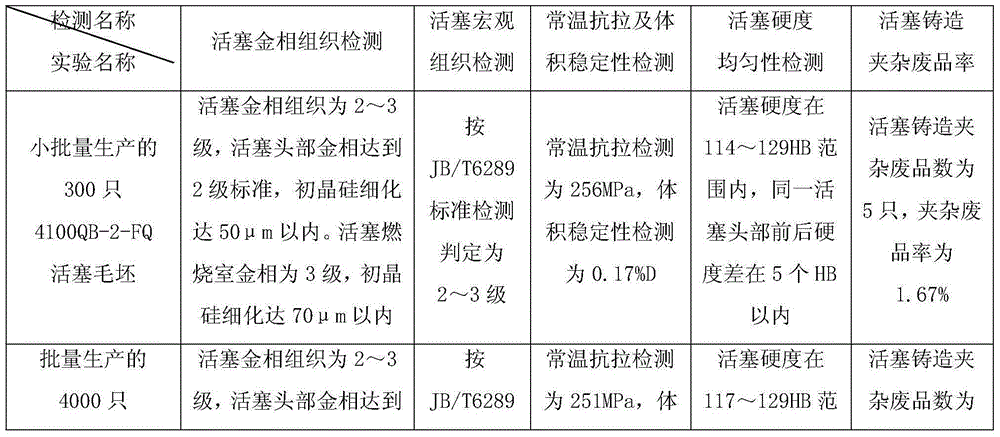

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of method utilizing aluminum-silicon series piston cuttings to cast high-quality aluminum parts, it comprises the following steps:

[0025] S1. Encapsulation and melting: After recovering the mechanically processed aluminum-silicon piston chips, dry them in time, and after the magnetic separation process, quickly add the chips to the natural gas reverberatory furnace for inclusion melting. The feeding time is 5 minutes, and the melting temperature is 740°C;

[0026] S2. Stand still at high temperature: heat up the natural gas reverberatory furnace to 850°C, keep it warm for 50 minutes, and generate aluminum liquid;

[0027] S3. Composition detection: Add slag cleaning agent JLAZ powder to the natural gas reverberatory furnace to remove slag. After removing slag, press metal magnesium into the bottom of the aluminum liquid. After standing still for 5 minutes, take samples for analysis and adjust until the content of each component in the aluminum liqu...

Embodiment 2

[0030] Embodiment 2: A kind of method utilizing aluminum-silicon series piston cuttings to cast high-quality aluminum parts, it comprises the following steps:

[0031] S1. Encapsulation and melting: After recovering the mechanically processed aluminum-silicon piston chips, dry them in time, and after the magnetic separation process, quickly add the chips into the natural gas reverberatory furnace for inclusion melting. The feeding time is 4 minutes, and the melting temperature is 780°C;

[0032] S2. Standing at high temperature: the natural gas reverberatory furnace is heated to 930°C and kept for 90 minutes to generate molten aluminum;

[0033] S3. Composition detection: Add slag cleaning agent JLAZ powder to the natural gas reverberatory furnace to remove slag. After removing slag, press metal magnesium into the bottom of the aluminum liquid. After standing still for 9 minutes, take samples for analysis and adjust until the content of each component in the aluminum liquid mee...

Embodiment 3

[0036] Embodiment 3: A kind of method utilizing aluminum-silicon series piston cuttings to cast high-quality aluminum parts, it comprises the following steps:

[0037] S1. Encapsulation and melting: After recovering the mechanically processed aluminum-silicon piston chips, dry them in time. After the magnetic separation process, quickly add the chips into the natural gas reverberatory furnace for inclusion melting. The feeding time is 3 minutes, and the melting temperature is 750°C. ;

[0038]S2. Standing at high temperature: the natural gas reverberatory furnace is heated to 865°C and kept for 58 minutes to generate molten aluminum;

[0039] S3. Composition detection: Add slag cleaning agent JLAZ powder to the natural gas reverberatory furnace to remove slag. After removing slag, press metal magnesium into the bottom of the aluminum liquid. After standing still for 6 minutes, take samples for analysis and adjust until the content of each component in the aluminum liquid meets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com