Flue gas recirculation high temperature air energy-saving and environmental protection combustion technology

A high-temperature air, energy-saving and environmentally-friendly technology, applied in the field of combustion technology, can solve problems such as no quantitative indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Flue gas circulation high-temperature air energy-saving and environmentally friendly combustion technology is to mix the flue gas after fuel combustion with combustion-supporting air and then heat them together to form high-temperature gas, which is then burned with fuel.

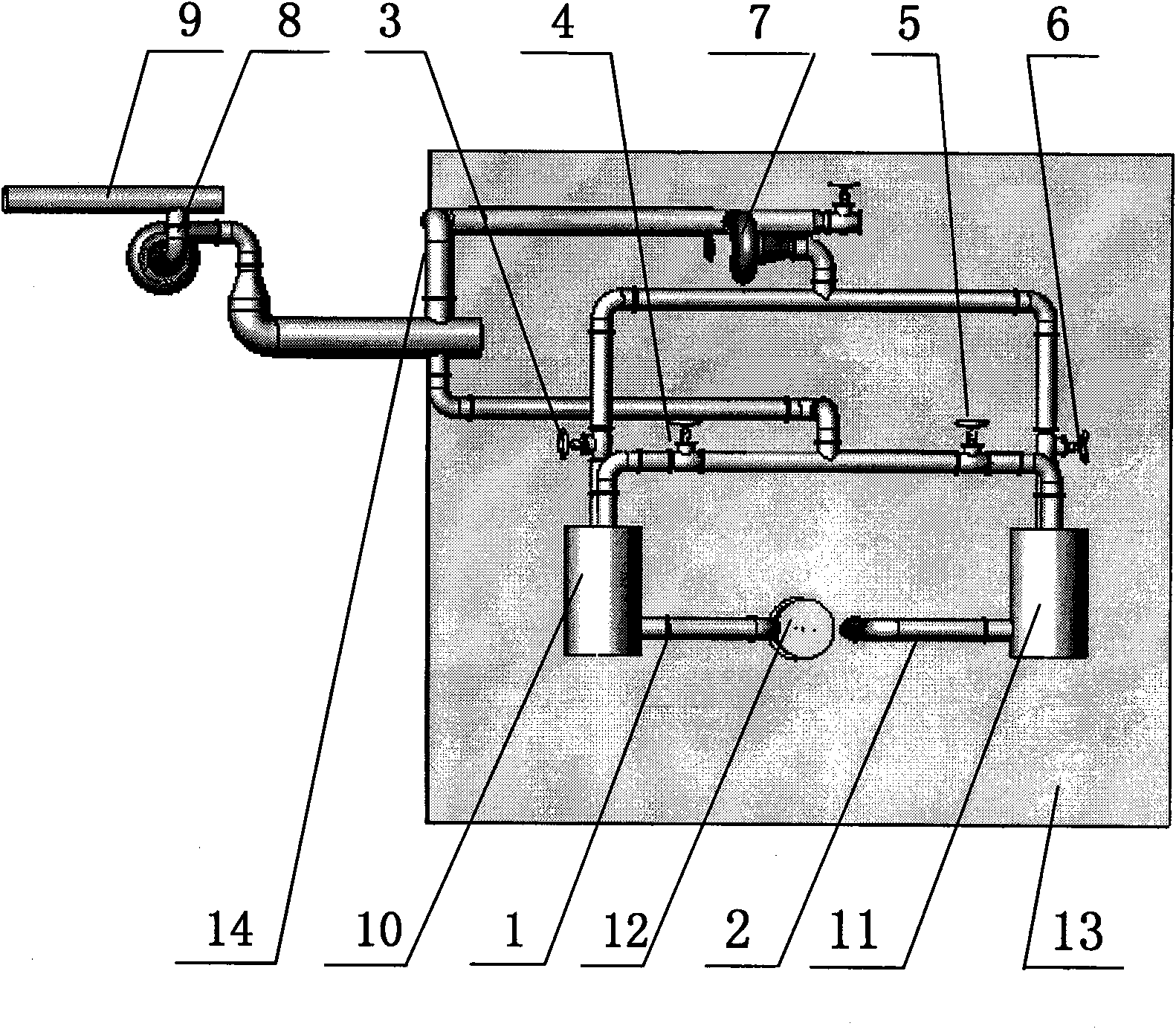

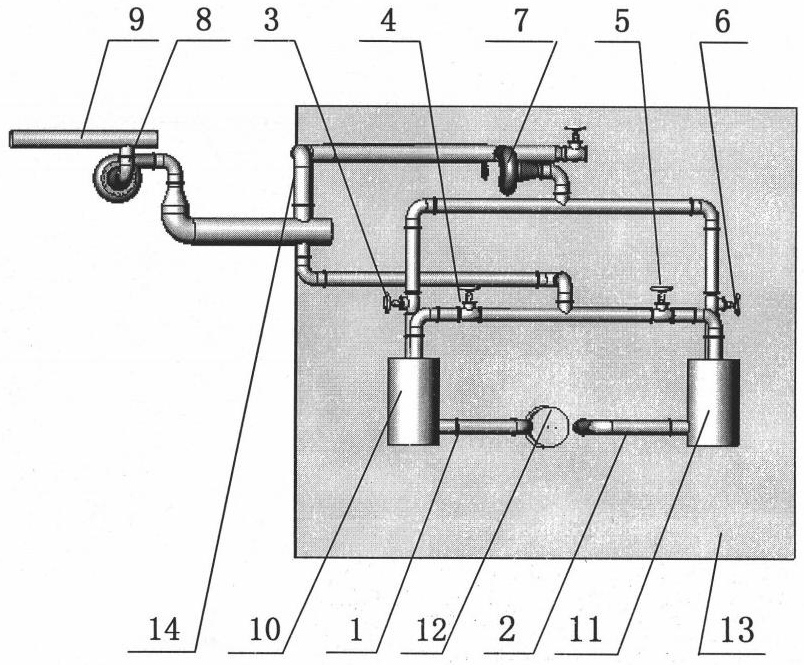

[0009] Below with reference to accompanying drawing, content of the present invention is further elaborated:

[0010] As shown in the figure, a duplex airflow channel is closely arranged on the left and right sides of the original burner position of the boiler furnace wall 13, which are channel 1 and channel 2 respectively. The two channels adopt full-duplex working mode. When the work starts, the control The valve 3 is opened, and the channel 1 starts to suck the high-temperature flue gas on the left side of the burner 12 under the action of the induced draft fan 7. , after a certain period of time, the control valve 6 is opened, and under the guidance of the induced draft fan 7, the channel 2 start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com