Novel waste aluminum smelting furnace

An aluminum smelting furnace, a new type of technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of pollution, large burning loss, low recovery rate, etc., achieve low energy consumption, eliminate temperature stratification, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention designs a new type of furnace suitable for smelting waste aluminum, breaks the traditional smelting process, abandons the practice of direct contact of flame with materials, and adopts a new technology of melting materials with aluminum water, which has high resistance to oxidation and burning loss , high yield, long service life of the furnace, and light environmental pollution.

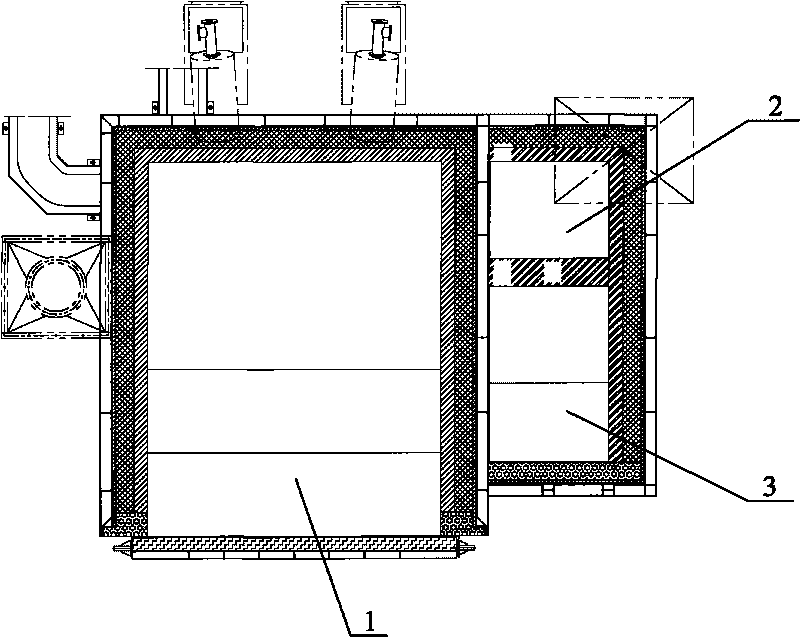

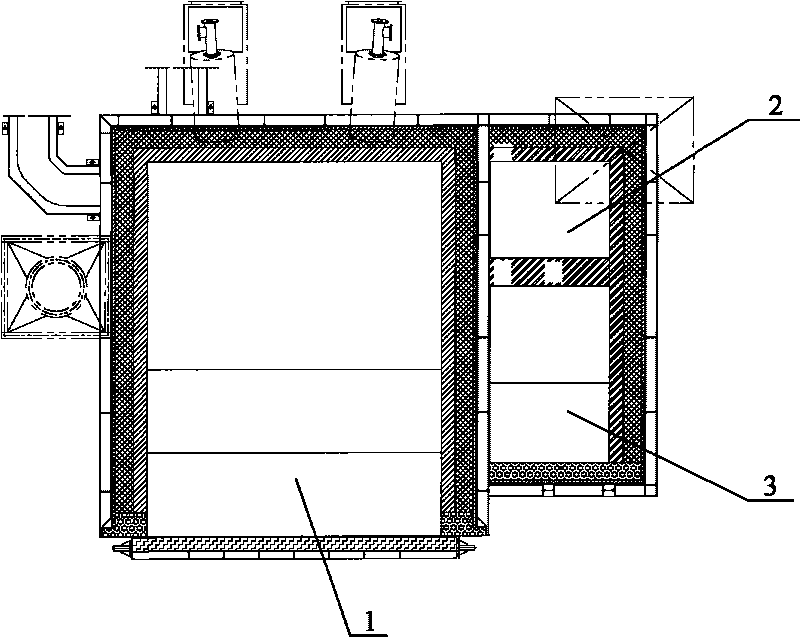

[0019] Such as figure 1 As shown, a new type of scrap aluminum smelting furnace includes a main smelting chamber 1 and a side well chamber, and a side well chamber is set on the side of the main smelting chamber. 2 and the feeding area 3 are connected with the main smelting chamber 1, and the pump area 2 is equipped with a circulation pump, and the type of the circulation pump is a mechanical circulation pump, an electromagnetic circulation pump or a permanent magnet circulation pump. There is a channel between the main smelting chamber 1 and the feeding area 3 and the pump are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com