Method for improving biological activity of titanium nitride ceramic coating by ozone treatment

A bioactive technology of titanium nitride ceramics, applied in coatings, medical science, prostheses, etc., can solve the problem of reducing the hardness or wear resistance of titanium nitride ceramics, changing the color of titanium nitride ceramics, and not suitable for preclinical treatment To achieve the effect of maintaining color, high hardness, improving biocompatibility and bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

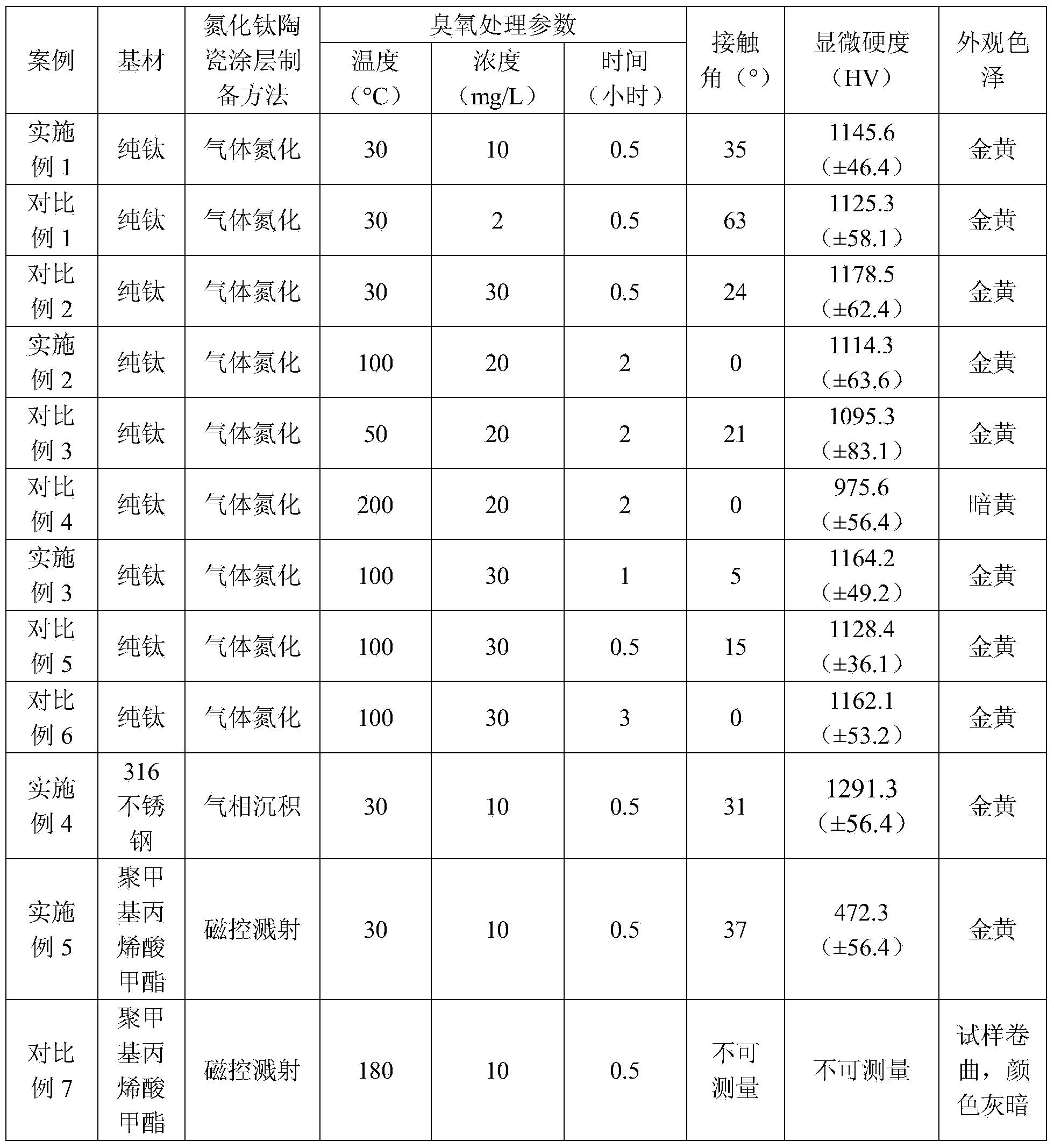

Embodiment 1

[0012] First, a titanium nitride ceramic layer is prepared on the surface of a disc-shaped pure titanium metal by gas nitriding method. The ceramic layer is golden yellow, the microhardness is HV1131.2 (±78.3), and the contact angle of distilled water on its surface is 70.1° . Secondly, the samples with titanium nitride ceramic coating can be ultrasonically cleaned and dried naturally. Next, put the sample into a fully cleaned and dried quartz tube. The quartz tube is placed horizontally, and silicon rubber plugs with reserved gas path holes are installed at both ends of the quartz tube. One end is connected to the ozone generator, and the other end is connected to the Ozone tail gas treatment device. After connecting the gas path, adjust the heating device to heat the quartz tube, and control the reaction temperature at 30°C. Introduce the gas generated by the oxygen source ozone generator, wherein the concentration of ozone is 10mg / L, the working pressure is maintained at ...

Embodiment 2

[0023] The treatment method is basically the same as in Example 1, except that the heating temperature is controlled at 100° C., the concentration of ozone is 20 mg / L, and the continuous gas supply time is 2 hours.

[0024] After treatment, the obtained sample is still golden yellow; the microhardness of the coating is HV1114.3 (±63.6), and there is no statistical difference compared with the untreated sample; while maintaining good wear resistance; the contact angle of distilled water is 0 °, significantly decreased compared with before treatment, which shows that the surface wettability of the titanium nitride ceramic layer treated by the method of the present invention is very good; the scanning electron microscope observation results show that the surface morphology of the sample treated with ozone does not occur. Variety.

Embodiment 3

[0033] The treatment method is basically the same as in Example 1, except that the heating temperature is controlled at 100° C., the concentration of ozone is 30 mg / L, and the continuous gas supply time is 1 hour.

[0034] After treatment, the obtained sample is still golden yellow; the microhardness of the coating is HV1164.2 (±49.27), which has no statistical difference compared with the untreated sample; while maintaining good wear resistance; the contact angle of distilled water is 5 °, and greatly decreased before the treatment, which shows that the surface wettability of the titanium nitride ceramic layer after the treatment of the method of the present invention is very good; the scanning electron microscope observation results show that the surface morphology of the sample treated with ozone has not changed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com